Electrical and Electronics - Lingaya's University

Electrical and Electronics - Lingaya's University

Electrical and Electronics - Lingaya's University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

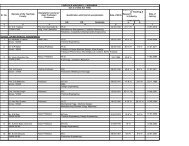

B.Tech. <strong>Electrical</strong> & <strong>Electronics</strong> Engineering (Regular)5 SIMPLE STRESSES AND STRAINS: Resistanceto deformation; Hook‘s law <strong>and</strong> stress-straindiagram; types of stresses; stresses <strong>and</strong> strains inbars of varying sections; stresses in compositebars; lateral strain <strong>and</strong> Poisson‘s ratio; volumetricstrain, modulus of rigidity <strong>and</strong> bulk modulus;relation between elastic constants.5. TORSION OF CIRCULAR SHAFTS, TORSIONFORMULA POWER TRANSMISSION6. SHEAR FORCE AND BENDING MOMENTS:Definitions: SF <strong>and</strong> BM diagrams forcantilevers, simply supported beams with orwithout overhang <strong>and</strong> calculation of max. BM<strong>and</strong> SF <strong>and</strong> point of contra-flexture under i)concentrated loads, ii) uniformly distributedloads over whole span or part of it iii)combination of concentrated <strong>and</strong> uniformlydistributed loads, iv) uniformly varying loads <strong>and</strong>application of moments; relationship betweenrate of loading, shear force <strong>and</strong> bendingmoments.7. KINEMATICS / KINETICS OF PARTICLES:Velocity <strong>and</strong> acceleration under rectilinear <strong>and</strong>circular motion; Newton‘s Second Law; D‘Alembertprinciple; Inertial system; Newton‘s Second Lawapplied to bodies under rectilinear <strong>and</strong> circularmotion; solutions of problems using D‘AlembertPrinciple <strong>and</strong> free-body diagrams.TEXT BOOKMeriam, J. L. ―Engineering Mechanics‖, John Wiley &Sons.REFERENCE BOOKS1. Beer, F.P. <strong>and</strong> Johnston, E.R. ―Mechanics ofMaterials‖, Tata McGraw Hill2. Shames, I.H. ―Engineering Mechanics‖, 4thEdition, Pearson Education, 20033. Pytel, A <strong>and</strong> Kiusalaas, J. Thomsom, ―Mechanicsof Materials‖, Brooks & Cole, 2003WEB REFERENCESwww.eCourses.ou.eduME-151ENGINEERINGMECHANICS LABL T P Cr0 0 2 1LIST OF EXPERIMENTS1. To study various forces <strong>and</strong> moments.2. Prove polygon law of coplanar forces, experimentswith pulley systems.3. Find support reactions for simply supported beam4. Find Forces in Truss elements5. Measuring forces in members of jib crane.6. Finding C.G. <strong>and</strong> MOI of various parts likeconnecting rod. Flywheel using various methods7. To find mechanical advantage <strong>and</strong> mechanicalefficiency of compound screw jack.8. To study various simple machines including geartrains e.g. Wedge; clock; sewing machine, etc.9. To conduct tensile test <strong>and</strong> determining ultimatetensile strength percentage elongation of steelspecimen10. To conduct compression test <strong>and</strong> determinecompressive strength of specimen11. To calculate VR, MA <strong>and</strong> efficiency of single,doubles <strong>and</strong> triple start worm <strong>and</strong> worm wheel12. To study slider crank mechanism of 2 stroke <strong>and</strong> 4stroke IC engine models13. To study <strong>and</strong> analyze gear trainsME-152WORKSHOP PRACTICEL T P Cr0 0 4 2OBJECTIVETo provide an overview of the basic productiontechniques <strong>and</strong> allied / supporting techniques used toproduce finished products from raw materials. In additionto theory, students will be given practical training onvarious basic production techniques. After going throughthis course, the students will be in a position tounderst<strong>and</strong> the working of a mechanical workshop.1. INTRODUCTION: Basic manufacturing processes<strong>and</strong> safety in workshop.2. ENGINEERING MATERIALS: Classification ofmaterials–their general mechanical properties <strong>and</strong>their selection3. CASTING PROCESSES: S<strong>and</strong> casting process;pattern making; types of moulding s<strong>and</strong>s, cores,mould making, melting <strong>and</strong> pouring of metal;Casting defects.4. MACHINING PROCESSES: Production ofcomponents involving turning; facing; taper turning;milling; shaping; planning <strong>and</strong> drilling operations.5. METAL FORMING PROCESSES: Sheet metalforming operations; shearing, bending, punching<strong>and</strong> blanking, forging processes as upsetting,drawing down, bending etc.6. JOINING PROCESSES: Metal arc welding; gaswelding; resistance welding; soldering <strong>and</strong>mechanical fastening processes.7. FITTING AND MAINTENANCE: Study of fittingtools, marking tools <strong>and</strong> measuring instrumentslike micrometer, vernier calipers <strong>and</strong> height gauge;introduction to some basic maintenancetechniques/processes.TEXT BOOKRaghuwanshi, B.S., ―A course in WorkshopTechnology, Vol. I & II‖, Dhanpatrai & Co.REFERENCE BOOKHazra & Chaudhary, ―Workshop Technology Vol. I & II‖,Asian Book Co.NOTES1. In all sections of workshop, students will studyabout the tools used, different operationsperformed <strong>and</strong> main parts of the machine2. Term final evaluation will be done on the basis ofdoing a practical job <strong>and</strong> viva-voce. There will beno theory paper on this subject.JOBS TO BE DONEA. Machine Shop1. To prepare a job on a lathe involving facing,turning, taper turning, step turning, radiusmaking <strong>and</strong> parting off.2. To prepare horizontal surface/ verticalsurface/ curved surface/ slot or v-grooves ona shaper / planer.36