xxxxxx - Alfa Laval

xxxxxx - Alfa Laval

xxxxxx - Alfa Laval

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

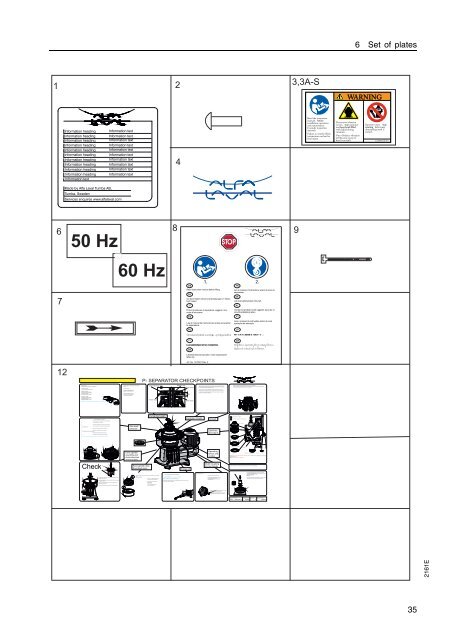

Before start-upIf the separator has been out of operation for:1 months or longerPre-lubricate the spindle bearings.6 months or longerPerform an Inspection serviceand make sure to pre-lubricatethe spindle bearings.Change the oil before starting.18 months or longerPerform an Overhaul serviceand make sure to pre-lubricatethe spindle bearings.Change the oil before starting.After service always run the separator continuously for at least 1 hour to ensure proper lubrication.Check the disc stack as follows1. Remove bowl hood, top disc and in- and outlet pipe.2. Add one disc to the disc stack.3. Fit the disc without caulks, top disc and bowl hood.4. Fit lock ring and fully compress disc stack with thecompression tool.5. If the lock ring enters the groove, repeat 1-4.6. If the lock ring does not enter the groove,this indicates correct stack pressure.7. Dismantle the bowl and remove one disc.8. Assemble the bowl with inlet and outlet pipe.NOTE! The number of discs stated in the SPC is a nominal value that might vary.Position the flat belt so that the spindle assembly can passthrough when lowering.Check the direction arrows on the belt and the machine platefor correct position.Make sure that the belt does not get smudged with oil orgrease during handling.Never use Molykote on any part on the spindle assembly.If the separator is out of operation for more than1 month:- Lift out the bowl.- Protect the spindle taper fromcorrosion by lubricating it withoil.- Keep the separator and bowlwell stored, dry and protectedfrom mechanical damage.Check for impact marks and corrosion on bowl body nave and spindlebore.Remedy as follows;1. Remove any impact marks usinga scraper and/or a whetstone.2. Remove rust using a fine-grinemery cloth(e.g. No.320).3. Finish with polishing paper(e.g. Number 600).Check the oil level. Top up when necessary.Don not overfill!Always remove the oil pin and plug before filling.Make sure that correct oil type is being used!Always follow the instructions in the Separator Manual and make sure thatthe oil bath is free from deposits.Always contact your <strong>Alfa</strong> <strong>Laval</strong> representative if you suspect that the depthof the corrosion damage exceeds 0,2 mm for bowl body and bowl hood (0,5for other parts) or if cracks have been found.Also Check for cracks. It is particulary important to inspect for cracks onrotating parts and especially between the discharge holes in the bowl wall.Do not continue to use the separator until it has been inspected and givenclearance for operation by <strong>Alfa</strong> <strong>Laval</strong>.If the blocks are worn;1. Clean the inside of the belt pulley.2. Fit new friction blocks. Make sure thatit is mounted as illustrated.All friction blocks should be replacedat the same time.When handling friction blocks wear a dust maskto make sure not to inhalate dust.Do not use compressed air for removal of anydust. Remove dust by vacuum or wet cloth.Check for erosion damages. Replace parts if erosion is suspected.Contact your <strong>Alfa</strong> <strong>Laval</strong> representative if you suspect that the depth of the damage exceeds0,2 mm bowl body, bowl hood. (0.5 mm for other parts).= Molykote 1000= Slide laquer + MolykoteBowl bodyDischarge slideOperating slideHolderClean the nozzle on the operating slide using a soft iron wire or a similar object.Approved / Date:Bowl hoodScrewOperating water ringNOTE! Replace screws and washers for holder with new ones included in IS-kit. Replace screws (IS-kit) foroperating water ring.Tighten with correct torque: = 30 Nm + 2Departement:Press the ball bearings down one at a time into thecoupling hub, preferably using a hydraulic press. Placethe spacing ring between them.Never re-fit used ballbearings.The ball bearings must not be heated as they are packedwith grease and sealed with plastic membranes.Revision:NutDocument No.6 Set of plates1 2 3,3A-S!WARNINGInformation headingInformation headingInformation headingInformation headingInformation headingInformation headingInformation headingInformation headingInformation headingInformation headingInformation textInformation textInformation textInformation textInformation textInformation textInformation textInformation textInformation textInformation textInformation text4Read the instructionmanuals beforeinstallation, operationand maintenance.Consider inspectionintervals.Failure to strictly followinstructions can lead tofatal injury.If excessive vibrationoccurs, stop separatorand keep bowl filledwith liquid duringrundown.Out of balance vibrationwill become worse ifbowl is not full.Separator must stoprotating before anydismantling work isstarted.1270018-02-V5Made by <strong>Alfa</strong> <strong>Laval</strong> Tumba AB,Tumba, SwedenServices enquires www.alfalaval.com6750 Hz60 Hz1.8 92.GBFRRead instruction manual before lifting.Lire le manuel d´instructions avant de lever leséparateur.DESEVor dem Heben immer erst Anleitungen im Handbuchlesen!Läs instruktionsboken före lyft.ITNLPrima di sollevare il separatore, leggere il manualed´istruzione.structihandleidingVordat het produkt wordt opgetild, eerst de in-lezen.ESLea el manual de instrucciones antes de levantarla separadora.RUPTLeia o manual de instruções antes de umaoperaçõo de elevaçõo.JPOeoednmdyekmk nomvhq aÄ qe hlpqoriuh lm.FILue käyttöohjeet ennen nostamista.DKGRDiabaste to egceiridio me tiz odhgiez protouBgalete th suskeuh apo to kibwtio.Læsinstruktionsmanualen, inden separatorenløftes op.Art. No. 1270001 Rev. 212P- SEPARATOR CHECKPOINTSHeight adjusting ringsSupport ringGuide screwAFrame hoodBowl hoodParing disc heightCorrosion / CracksErosionDisc stackpressureLubricatebowl partsCheckClean spindleassembly andcheck directionarrow on beltBowl spindle coneBowl body naveChange oilOperatingdevice andnozzlesClutch couplingFriction blocksSZM /2009-08-19PCDD35759392161E35