Hydrogen and its competitors, 2004

Hydrogen and its competitors, 2004

Hydrogen and its competitors, 2004

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

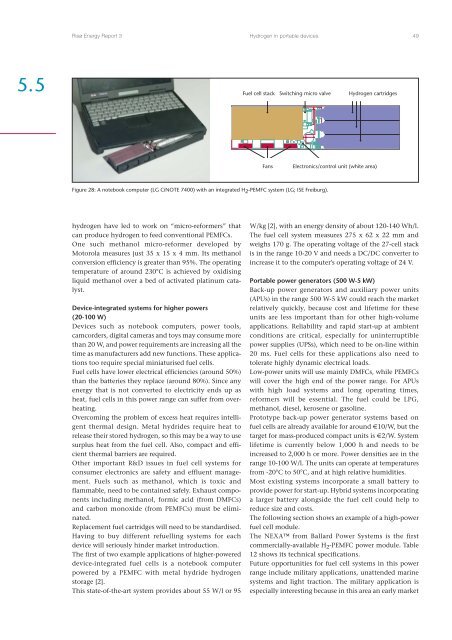

Risø Energy Report 3<strong>Hydrogen</strong> in portable devices 495.5Fuel cell stack Switching micro valve<strong>Hydrogen</strong> cartridgesFansElectronics/control unit (white area)Figure 28: A notebook computer (LG CiNOTE 7400) with an integrated H 2 -PEMFC system (LG; ISE Freiburg).hydrogen have led to work on “micro-reformers” thatcan produce hydrogen to feed conventional PEMFCs.One such methanol micro-reformer developed byMotorola measures just 35 x 15 x 4 mm. Its methanolconversion efficiency is greater than 95%. The operatingtemperature of around 230°C is achieved by oxidisingliquid methanol over a bed of activated platinum catalyst.Device-integrated systems for higher powers(20-100 W)Devices such as notebook computers, power tools,camcorders, digital cameras <strong>and</strong> toys may consume morethan 20 W, <strong>and</strong> power requirements are increasing all thetime as manufacturers add new functions. These applicationstoo require special miniaturised fuel cells.Fuel cells have lower electrical efficiencies (around 50%)than the batteries they replace (around 80%). Since anyenergy that is not converted to electricity ends up asheat, fuel cells in this power range can suffer from overheating.Overcoming the problem of excess heat requires intelligentthermal design. Metal hydrides require heat torelease their stored hydrogen, so this may be a way to usesurplus heat from the fuel cell. Also, compact <strong>and</strong> efficientthermal barriers are required.Other important R&D issues in fuel cell systems forconsumer electronics are safety <strong>and</strong> effluent management.Fuels such as methanol, which is toxic <strong>and</strong>flammable, need to be contained safely. Exhaust componentsincluding methanol, formic acid (from DMFCs)<strong>and</strong> carbon monoxide (from PEMFCs) must be eliminated.Replacement fuel cartridges will need to be st<strong>and</strong>ardised.Having to buy different refuelling systems for eachdevice will seriously hinder market introduction.The first of two example applications of higher-powereddevice-integrated fuel cells is a notebook computerpowered by a PEMFC with metal hydride hydrogenstorage [2].This state-of-the-art system provides about 55 W/l or 95W/kg [2], with an energy density of about 120-140 Wh/l.The fuel cell system measures 275 x 62 x 22 mm <strong>and</strong>weighs 170 g. The operating voltage of the 27-cell stackis in the range 10-20 V <strong>and</strong> needs a DC/DC converter toincrease it to the computer's operating voltage of 24 V.Portable power generators (500 W-5 kW)Back-up power generators <strong>and</strong> auxiliary power un<strong>its</strong>(APUs) in the range 500 W-5 kW could reach the marketrelatively quickly, because cost <strong>and</strong> lifetime for theseun<strong>its</strong> are less important than for other high-volumeapplications. Reliability <strong>and</strong> rapid start-up at ambientconditions are critical, especially for uninterruptiblepower supplies (UPSs), which need to be on-line within20 ms. Fuel cells for these applications also need totolerate highly dynamic electrical loads.Low-power un<strong>its</strong> will use mainly DMFCs, while PEMFCswill cover the high end of the power range. For APUswith high load systems <strong>and</strong> long operating times,reformers will be essential. The fuel could be LPG,methanol, diesel, kerosene or gasoline.Prototype back-up power generator systems based onfuel cells are already available for around €10/W, but thetarget for mass-produced compact un<strong>its</strong> is €2/W. Systemlifetime is currently below 1,000 h <strong>and</strong> needs to beincreased to 2,000 h or more. Power densities are in therange 10-100 W/l. The un<strong>its</strong> can operate at temperaturesfrom -20°C to 50°C, <strong>and</strong> at high relative humidities.Most existing systems incorporate a small battery toprovide power for start-up. Hybrid systems incorporatinga larger battery alongside the fuel cell could help toreduce size <strong>and</strong> costs.The following section shows an example of a high-powerfuel cell module.The NEXA from Ballard Power Systems is the firstcommercially-available H 2 -PEMFC power module. Table12 shows <strong>its</strong> technical specifications.Future opportunities for fuel cell systems in this powerrange include military applications, unattended marinesystems <strong>and</strong> light traction. The military application isespecially interesting because in this area an early market