No. 1031 - Miljøstyrelsen

No. 1031 - Miljøstyrelsen

No. 1031 - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Curing of one-component RTV silicones starts<br />

when the compounds are exposed to atmospheric<br />

moisture during application. The crosslinking<br />

agents are tri- or tetrafunctional silanes<br />

containing hydrolyseable Si-O or Si-N bonds.<br />

Depending on the used cross-linking agent different<br />

compounds are formed as cleavage product<br />

and will be released during the curing process<br />

(see Table 1.1)<br />

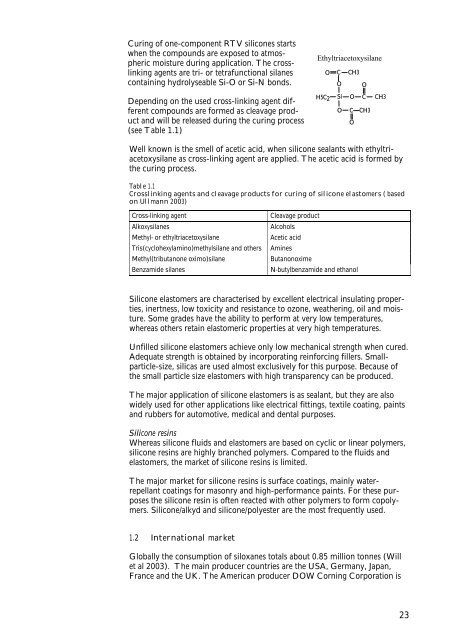

Well known is the smell of acetic acid, when silicone sealants with ethyltriacetoxysilane<br />

as cross-linking agent are applied. The acetic acid is formed by<br />

the curing process.<br />

Table 1.1<br />

Crosslinking agents and cleavage products for curing of silicone elastomers ( based<br />

on Ullmann 2003)<br />

Cross-linking agent Cleavage product<br />

Alkoxysilanes Alcohols<br />

Methyl- or ethyltriacetoxysilane Acetic acid<br />

Tris(cyclohexylamino)methylsilane and others Amines<br />

Methyl(tributanone oximo)silane Butanonoxime<br />

Benzamide silanes N-butylbenzamide and ethanol<br />

Silicone elastomers are characterised by excellent electrical insulating properties,<br />

inertness, low toxicity and resistance to ozone, weathering, oil and moisture.<br />

Some grades have the ability to perform at very low temperatures,<br />

whereas others retain elastomeric properties at very high temperatures.<br />

Unfilled silicone elastomers achieve only low mechanical strength when cured.<br />

Adequate strength is obtained by incorporating reinforcing fillers. Smallparticle-size,<br />

silicas are used almost exclusively for this purpose. Because of<br />

the small particle size elastomers with high transparency can be produced.<br />

The major application of silicone elastomers is as sealant, but they are also<br />

widely used for other applications like electrical fittings, textile coating, paints<br />

and rubbers for automotive, medical and dental purposes.<br />

Silicone resins<br />

Whereas silicone fluids and elastomers are based on cyclic or linear polymers,<br />

silicone resins are highly branched polymers. Compared to the fluids and<br />

elastomers, the market of silicone resins is limited.<br />

The major market for silicone resins is surface coatings, mainly waterrepellant<br />

coatings for masonry and high-performance paints. For these purposes<br />

the silicone resin is often reacted with other polymers to form copolymers.<br />

Silicone/alkyd and silicone/polyester are the most frequently used.<br />

1.2 International market<br />

Ethyltriacetoxysilane<br />

C CH3<br />

Globally the consumption of siloxanes totals about 0.85 million tonnes (Will<br />

et al 2003). The main producer countries are the USA, Germany, Japan,<br />

France and the UK. The American producer DOW Corning Corporation is<br />

O<br />

H5C2<br />

O<br />

Si<br />

O<br />

O C CH3<br />

O C CH3<br />

O<br />

23