No. 1031 - Miljøstyrelsen

No. 1031 - Miljøstyrelsen

No. 1031 - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

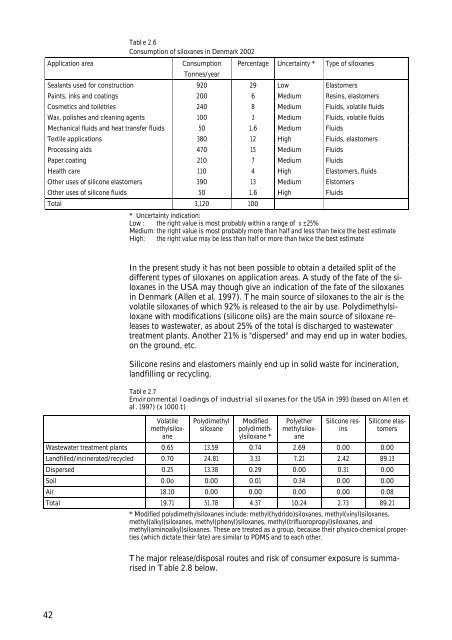

Table 2.6<br />

Consumption of siloxanes in Denmark 2002<br />

Application area Consumption Percentage Uncertainty * Type of siloxanes<br />

42<br />

Tonnes/year<br />

Sealants used for construction 920 29 Low Elastomers<br />

Paints, inks and coatings 200 6 Medium Resins, elastomers<br />

Cosmetics and toiletries 240 8 Medium Fluids, volatile fluids<br />

Wax, polishes and cleaning agents 100 3 Medium Fluids, volatile fluids<br />

Mechanical fluids and heat transfer fluids 50 1.6 Medium Fluids<br />

Textile applications 380 12 High Fluids, elastomers<br />

Processing aids 470 15 Medium Fluids<br />

Paper coating 210 7 Medium Fluids<br />

Health care 110 4 High Elastomers, fluids<br />

Other uses of silicone elastomers 390 13 Medium Elstomers<br />

Other uses of silicone fluids 50 1.6 High Fluids<br />

Total 3,120 100<br />

* Uncertainty indication:<br />

Low : the right value is most probably within a range of x ±25%<br />

Medium: the right value is most probably more than half and less than twice the best estimate<br />

High: the right value may be less than half or more than twice the best estimate<br />

In the present study it has not been possible to obtain a detailed split of the<br />

different types of siloxanes on application areas. A study of the fate of the siloxanes<br />

in the USA may though give an indication of the fate of the siloxanes<br />

in Denmark (Allen et al. 1997). The main source of siloxanes to the air is the<br />

volatile siloxanes of which 92% is released to the air by use. Polydimethylsiloxane<br />

with modifications (silicone oils) are the main source of siloxane releases<br />

to wastewater, as about 25% of the total is discharged to wastewater<br />

treatment plants. Another 21% is "dispersed" and may end up in water bodies,<br />

on the ground, etc.<br />

Silicone resins and elastomers mainly end up in solid waste for incineration,<br />

landfilling or recycling.<br />

Table 2.7<br />

Environmental loadings of industrial siloxanes for the USA in 1993 (based on Allen et<br />

al. 1997) (x 1000 t)<br />

Volatile<br />

methylsiloxane<br />

Polydimethyl<br />

siloxane<br />

Modified<br />

polydimethylsiloxane<br />

*<br />

Polyether<br />

methylsiloxane<br />

Silicone resins<br />

Silicone elastomers<br />

Wastewater treatment plants 0.65 13.59 0.74 2.69 0.00 0.00<br />

Landfilled/incinerated/recycled 0.70 24.81 3.33 7.21 2.42 89.13<br />

Dispersed 0.25 13.38 0.29 0.00 0.31 0.00<br />

Soil 0.0o 0.00 0.01 0.34 0.00 0.00<br />

Air 18.10 0.00 0.00 0.00 0.00 0.08<br />

Total 19.71 51.78 4.37 10.24 2.73 89.21<br />

* Modified polydimethylsiloxanes include: methyl(hydrido)siloxanes, methyl(vinyl)siloxanes,<br />

methyl(alkyl)siloxanes, methyl(phenyl)siloxanes, methyl(trifluoropropyl)siloxanes, and<br />

methyl(aminoalkyl)siloxanes. These are treated as a group, because their physico-chemical properties<br />

(which dictate their fate) are similar to PDMS and to each other.<br />

The major release/disposal routes and risk of consumer exposure is summarised<br />

in Table 2.8 below.