- Page 1:

ProductGuideRev. 06 12/06

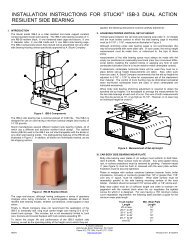

- Page 4 and 5:

Table of Contents4. Hydraulic Stabi

- Page 6 and 7:

1. ScopeThis pocket guide provides

- Page 8:

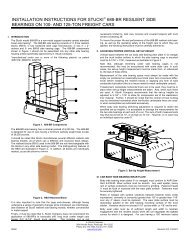

Side BearingsFig. 2.1 — Shear Sid

- Page 14:

Side BearingsFig. 2.7 — RetroXT S

- Page 25 and 26:

Side Side Bearings BearingsFig. 2.1

- Page 27 and 28:

Side Side Bearings BearingsFig. 2.2

- Page 29 and 30:

Side Side Bearings BearingsFig. 2.2

- Page 31 and 32:

Side Side Bearings BearingsFig. 2.2

- Page 33 and 34:

End Closure: End closures must be i

- Page 36:

Side BearingsShop SET UP5-1/8" ± 1

- Page 40 and 41:

Side BearingsYard Inspection: Verti

- Page 42 and 43:

Side BearingsShop SET UP3/4" ± 1/1

- Page 44 and 45:

Side BearingsShop InspectionGeneral

- Page 46 and 47:

Side BearingsResilient Element: Res

- Page 48 and 49:

Side BearingsLoad Cell Testing: A s

- Page 50 and 51:

Side BearingsThese measurements ass

- Page 52 and 53:

Side BearingsFig. 2.32 — Vertical

- Page 54 and 55:

Side BearingsFig. 2.34 — Setup He

- Page 56 and 57:

Side BearingsTo increase the setup

- Page 58 and 59:

Table 3.1Friction Elements*Requires

- Page 60 and 61:

Friction ElementsFig. 3.3 — RFE-5

- Page 62 and 63:

Friction ElementsFig. 3.7 — Wear

- Page 64 and 65:

Friction ElementsThe upper corners

- Page 66 and 67:

Friction ElementsIf wedge rise meas

- Page 68 and 69:

4. Hydraulic StabilizersStucki hydr

- Page 70 and 71:

Yard and Shop InspectionHydraulic S

- Page 72 and 73:

Condition A. The oil level in the r

- Page 74 and 75:

HS-7 and HS-7100 units removed onac

- Page 76 and 77:

International ProductsAustralia, Ne

- Page 78 and 79:

International ProductsFig. 5.3 —

- Page 80 and 81:

International Products675-RXL Side

- Page 82 and 83:

International Products656-CRL Side

- Page 84 and 85:

International ProductsThe JOEY Seri

- Page 86 and 87:

International ProductsSeveral sligh

- Page 88 and 89:

International ProductsSA-5000-2R Si

- Page 90 and 91:

International ProductsAustralia and

- Page 92 and 93:

International ProductsRFE-3262 Resi

- Page 94 and 95:

6. Brake BeamsBrake BeamsFig. 6.1

- Page 96 and 97:

Brake BeamsInspectionReplacement of

- Page 98 and 99:

PinRetainerBrake BeamsStrutLeverSlo

- Page 100 and 101:

Reconditioning Services7. Reconditi

- Page 102 and 103:

Reconditioning ServicesFig. 7.1 —

- Page 104 and 105:

Reconditioning ServicesFriction Com

- Page 106 and 107:

Reconditioning ServicesGears which

- Page 108 and 109:

Reconditioning ServicesNew parts in

- Page 110 and 111:

Product Index (continued)Product In

- Page 114 and 115:

Reconditioning ServicesImproving Ri

- Page 116 and 117:

Table of Contents4. Hydraulic Stabi

- Page 118 and 119:

1. ScopeThis pocket guide provides

- Page 120 and 121:

Side BearingsFig. 2.1 — Shear Sid

- Page 122 and 123:

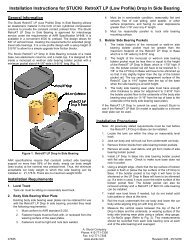

Side BearingsFig. 2.3 — Compact C

- Page 124 and 125:

Side BearingsFig. 2.5 — RetroXT L

- Page 126 and 127:

Side BearingsFig. 2.7 — RetroXT S

- Page 128 and 129:

Side BearingsFig. 2.9 — RetroXT 5

- Page 130 and 131:

Side BearingsFig. 2.11 — 656-CR,

- Page 132 and 133:

Side BearingsFig. 2.13 — 690-RL,

- Page 134 and 135:

Side BearingsFig. 2.15 — 675-RL,

- Page 136 and 137:

Side BearingsFig. 2.17 — ISB-9DR,

- Page 138 and 139:

Side BearingsFig. 2.19 — ISB-10,

- Page 140 and 141:

Side BearingsFig. 2.21 — 656-SLB,

- Page 142 and 143:

Side BearingsFig. 2.23 — 688-BNot

- Page 144 and 145:

Side BearingsYard InspectionGeneral

- Page 146 and 147:

Side BearingsRocker: Rockers may no

- Page 148 and 149: Side BearingsShop SET UP5-1/8" ± 1

- Page 150 and 151: Side BearingsIf reasonably level tr

- Page 152 and 153: Side BearingsYard Inspection: Verti

- Page 154 and 155: Side BearingsShop SET UP3/4" ± 1/1

- Page 156 and 157: Side BearingsShop InspectionGeneral

- Page 158 and 159: Side BearingsResilient Element: Res

- Page 160 and 161: Side BearingsLoad Cell Testing: A s

- Page 162 and 163: Side BearingsThese measurements ass

- Page 164 and 165: Side BearingsFig. 2.32 — Vertical

- Page 166 and 167: Side BearingsFig. 2.34 — Setup He

- Page 168 and 169: Side BearingsTo increase the setup

- Page 170 and 171: Table 3.1Friction Elements*Requires

- Page 172 and 173: Friction ElementsFig. 3.3 — RFE-5

- Page 174 and 175: Friction ElementsFig. 3.7 — Wear

- Page 176 and 177: Friction ElementsThe upper corners

- Page 178 and 179: Friction ElementsIf wedge rise meas

- Page 180 and 181: 4. Hydraulic StabilizersStucki hydr

- Page 182 and 183: Yard and Shop InspectionHydraulic S

- Page 184 and 185: Condition A. The oil level in the r

- Page 186 and 187: HS-7 and HS-7100 units removed onac

- Page 188 and 189: International ProductsAustralia, Ne

- Page 190 and 191: International ProductsFig. 5.3 —

- Page 192 and 193: International Products675-RXL Side

- Page 194 and 195: International Products656-CRL Side

- Page 196 and 197: International ProductsThe JOEY Seri

- Page 200 and 201: International ProductsSA-5000-2R Si

- Page 202 and 203: International ProductsAustralia and

- Page 204 and 205: International ProductsRFE-3262 Resi

- Page 206 and 207: 6. Brake BeamsBrake BeamsFig. 6.1

- Page 208 and 209: Brake BeamsInspectionReplacement of

- Page 210 and 211: PinRetainerBrake BeamsStrutLeverSlo

- Page 212 and 213: Reconditioning Services7. Reconditi

- Page 214 and 215: Reconditioning ServicesFig. 7.1 —

- Page 216 and 217: Reconditioning ServicesFriction Com

- Page 218 and 219: Reconditioning ServicesGears which

- Page 220 and 221: Reconditioning ServicesNew parts in

- Page 222 and 223: Product Index (continued)Product In

- Page 226: Reconditioning ServicesImproving Ri