priciples of insecticide use in rice ipm

priciples of insecticide use in rice ipm

priciples of insecticide use in rice ipm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Insecticides <strong>in</strong> Rice IPM (DRR)<br />

anaerobic conditions after the oxygen is depleted. The PH <strong>of</strong> the soil shows a tendency to reach the near<br />

neutral, although may not exactly be neutral. The anaerobic bacteria and other microbes take the position<br />

<strong>of</strong> aerobic bacteria and other organisms present under aerobically grown crops.<br />

Under these conditions if <strong><strong>in</strong>secticide</strong> or urea fertilizer is placed <strong>in</strong> the root zone <strong>of</strong> <strong>rice</strong> plants, these are<br />

not subjected to oxidation which usually renders them to rapid degradation. Instead, these rema<strong>in</strong> <strong>in</strong> the<br />

same state for longer period. These chemicals are also near the root system, and hence are more easily<br />

absorbed <strong>in</strong>to the plant. The chemicals are not subjected to losses through volatilization, and leach<strong>in</strong>g.<br />

Therefore, several attempts were made to develop practical methods <strong>of</strong> plac<strong>in</strong>g the <strong><strong>in</strong>secticide</strong>s <strong>in</strong> the<br />

root zone <strong>of</strong> <strong>rice</strong> plants. Pathak et. al. (1974) at IRRI took <strong>in</strong>itiative <strong>in</strong> this l<strong>in</strong>e <strong>of</strong> work. Forty one<br />

<strong><strong>in</strong>secticide</strong>s were evaluated under greenho<strong>use</strong> conditions as granules, tablets or capsules placed at a<br />

depth <strong>of</strong> 2.5 cm at a rate equivalent <strong>of</strong> 2 kg a.i./ha <strong>in</strong> the root zone <strong>of</strong> potted <strong>rice</strong> plants by us<strong>in</strong>g<br />

Nephotettix virescens, Nilaparvata lugens and Chilo suppressalis as test <strong>in</strong>sects. In their <strong>in</strong>itial evaluation,<br />

about 25 compounds were effective aga<strong>in</strong>st N. virescens, while a lesser number exhibited good efficacy<br />

aga<strong>in</strong>st N. lugens and C. suppressalis. In further field trials, it was observed that a s<strong>in</strong>gle application <strong>of</strong><br />

carb<strong>of</strong>uran, cartap or chlordimeform even at 0.5 kg a.i./ha controlled the <strong>in</strong>sect pests equal to 3-4<br />

applications <strong>of</strong> the same <strong><strong>in</strong>secticide</strong>s <strong>in</strong> the stand<strong>in</strong>g water.<br />

Encouraged by these results, attempts were <strong>in</strong>itiated at DRR (formerly AICRIP) where several <strong><strong>in</strong>secticide</strong>s<br />

were tested by root-zone application method both <strong>in</strong> lead research and coord<strong>in</strong>ation (AICRIP 1977-80).<br />

Similar attempts were also made <strong>in</strong> other countries like Indonesia (Shagir and Van, 1976), Korea (Choi et<br />

al., 1977), India (Krishnaiah et. al, 1988b; Reddy and Krishnaiah, 1993) and Ch<strong>in</strong>a (Chiu et. al, 1980).<br />

In the beg<strong>in</strong>n<strong>in</strong>g, the <strong><strong>in</strong>secticide</strong> granules were mixed <strong>in</strong> a suitable soil, and mud balls were prepared and<br />

these mud-balls were placed <strong>in</strong> the root zone @ 1 for each hill or 1 for 2 or 4 hills. However, this method<br />

was laborious, time consum<strong>in</strong>g and many a situations uneconomical.<br />

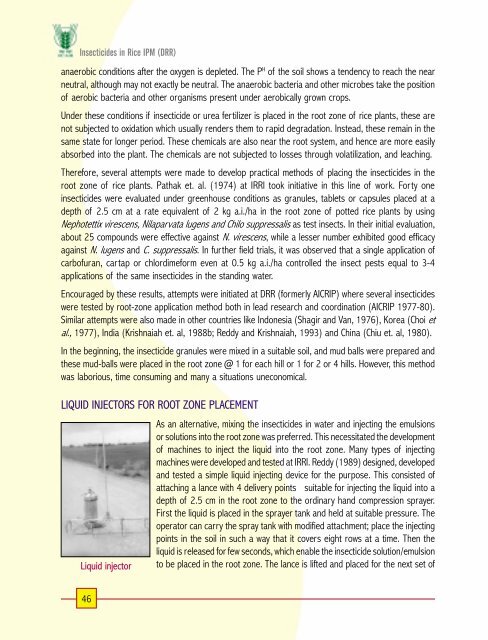

LIQUID INJECTORS FOR ROOT ZONE PLACEMENT<br />

Liquid <strong>in</strong>jector<br />

46<br />

As an alternative, mix<strong>in</strong>g the <strong><strong>in</strong>secticide</strong>s <strong>in</strong> water and <strong>in</strong>ject<strong>in</strong>g the emulsions<br />

or solutions <strong>in</strong>to the root zone was preferred. This necessitated the development<br />

<strong>of</strong> mach<strong>in</strong>es to <strong>in</strong>ject the liquid <strong>in</strong>to the root zone. Many types <strong>of</strong> <strong>in</strong>ject<strong>in</strong>g<br />

mach<strong>in</strong>es were developed and tested at IRRI. Reddy (1989) designed, developed<br />

and tested a simple liquid <strong>in</strong>ject<strong>in</strong>g device for the purpose. This consisted <strong>of</strong><br />

attach<strong>in</strong>g a lance with 4 delivery po<strong>in</strong>ts suitable for <strong>in</strong>ject<strong>in</strong>g the liquid <strong>in</strong>to a<br />

depth <strong>of</strong> 2.5 cm <strong>in</strong> the root zone to the ord<strong>in</strong>ary hand compression sprayer.<br />

First the liquid is placed <strong>in</strong> the sprayer tank and held at suitable pressure. The<br />

operator can carry the spray tank with modified attachment; place the <strong>in</strong>ject<strong>in</strong>g<br />

po<strong>in</strong>ts <strong>in</strong> the soil <strong>in</strong> such a way that it covers eight rows at a time. Then the<br />

liquid is released for few seconds, which enable the <strong><strong>in</strong>secticide</strong> solution/emulsion<br />

to be placed <strong>in</strong> the root zone. The lance is lifted and placed for the next set <strong>of</strong>