PATCHFIX EPOXY BINDER - Bostik Hong Kong Limited

PATCHFIX EPOXY BINDER - Bostik Hong Kong Limited

PATCHFIX EPOXY BINDER - Bostik Hong Kong Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

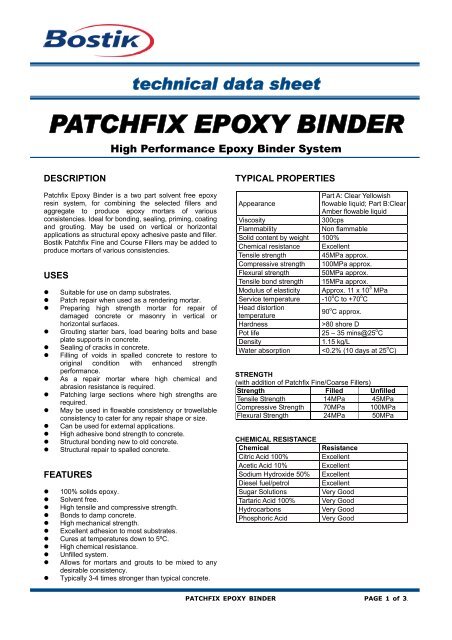

technical data sheet<strong>PATCHFIX</strong> <strong>EPOXY</strong> <strong>BINDER</strong>High Performance Epoxy Binder SystemDESCRIPTIONPatchfix Epoxy Binder is a two part solvent free epoxyresin system, for combining the selected fillers andaggregate to produce epoxy mortars of variousconsistencies. Ideal for bonding, sealing, priming, coatingand grouting. May be used on vertical or horizontalapplications as structural epoxy adhesive paste and filler.<strong>Bostik</strong> Patchfix Fine and Course Fillers may be added toproduce mortars of various consistencies.USES• Suitable for use on damp substrates.• Patch repair when used as a rendering mortar.• Preparing high strength mortar for repair ofdamaged concrete or masonry in vertical orhorizontal surfaces.• Grouting starter bars, load bearing bolts and baseplate supports in concrete.• Sealing of cracks in concrete.• Filling of voids in spalled concrete to restore tooriginal condition with enhanced strengthperformance.• As a repair mortar where high chemical andabrasion resistance is required.• Patching large sections where high strengths arerequired.• May be used in flowable consistency or trowellableconsistency to cater for any repair shape or size.• Can be used for external applications.• High adhesive bond strength to concrete.• Structural bonding new to old concrete.• Structural repair to spalled concrete.FEATURES• 100% solids epoxy.• Solvent free.• High tensile and compressive strength.• Bonds to damp concrete.• High mechanical strength.• Excellent adhesion to most substrates.• Cures at temperatures down to 5ºC.• High chemical resistance.• Unfilled system.• Allows for mortars and grouts to be mixed to anydesirable consistency.• Typically 3-4 times stronger than typical concrete.TYPICAL PROPERTIESPart A: Clear YellowishAppearanceflowable liquid; Part B:ClearAmber flowable liquidViscosity300cpsFlammabilityNon flammableSolid content by weight 100%Chemical resistance ExcellentTensile strength45MPa approx.Compressive strength 100MPa approx.Flexural strength 50MPa approx.Tensile bond strength 15MPa approx.Modulus of elasticity Approx. 11 x 10 3 MPaService temperature -10 o C to +70 o CHead distortiontemperature90 o C approx.Hardness>80 shore DPot life25 – 35 mins@25 o CDensity1.15 kg/LWater absorption

PERFORMANCE PROPERTIESThe following may be used as a guide for the quantity of Patchfix Fine Filler required to obtain a specific consistencywhen Patchfix Epoxy Binder is used as a binder.Litre of PatchfixEpoxy BinderApprox. weightof PatchfixFine FillerApprox. yield(litres)(Resin & Fillers)MixedConsistencyPot Life 20 o C(min approx.)CompressiveStrength at 7 daysMPa approx.Tensile Strengthat 7 days MPaapprox.Flexural Strengthat 7 days MPaapprox1 1.7 2 Very Fluid Grout 35-45 80 16 281 3.4 3 Fluid Grout 40-50 75 14 261 5.1 4 Pourable Grout 55-65 70 13 261 6.8 5 Stiff Paste 55-65 70 11 251 8.5 6 Trowellable Mortar 55-64 70 11 241 10.2 7Dry MortarTrowellable65-70 60 10 21The following may be used as a guide for the quantity of Patchfix Coarse Filler required to obtain a specific consistencywhen Patchfix Epoxy Binder is used as a binder.Litre of PatchfixEpoxy BinderApprox. weightof PatchfixCoarse FillerApprox. yield(litres)(Resin & Fillers)MixedConsistencyPot Life 20 o C(min approx.)CompressiveStrength at 7 daysMPa approx.Tensile Strengthat 7 days MPaapprox.Flexural Strengthat 7 days MPaapprox1 1.5 2 Very Fluid Grout 35-45 80 16 271 2.3 2.5 Fluid Grout 40-50 77 14 261 3.0 3 Pourable Grout 55-65 75 13 261 4.5 4 Stiff Paste 55-65 70 11 251 6.0 5 Trowellable Mortar 55-64 67 10 231 7.5 6Dry MortarTrowellable65-70 65 10 20APPLICATION INSTRUCTIONSSURFACE PREPARATIONClean the surface and remove any dust, unsoundmaterial, plaster, oil, paint, grease, corrosion deposits oralgae. Roughen the surface and remove any laitance andexpose aggregate by light scabbling or grit-blasting.Steam cleaning, detergent scrubbing or the use ofproprietary degreaser should remove oil and greasedeposits.All residual ponding water must be removed. Thesubstrate may be moist but not wet. All anchor bolt holesmust be free of water and debris prior to placing ofPatchfix Epoxy Binder. Steel surfaces such asreinforcement bars should be grit-blasted or scabbled toremove any corrosion.MIXINGThe mix ratio is 2:1 by volume, 2 parts Part A and 1 partPart B. Any steel reinforcement and formwork should beprepared, cut to size and shape and made ready forassembly before mixing commences. Care should betaken to ensure that Patchfix Epoxy Binder is thoroughlymixed. The entire contents of the hardener (Part B) tinshould then be poured into the base (Part A) tin and thetwo materials thoroughly mixed using a suitableslow-speed drill and high shear mixing paddle. Mix for 2minutes until a fully uniform colour is obtained, the sidesof the tins should be scraped, mixing should continue fora further 2 minutes.To facilitate mixing and application at temperatures below10 o C, the separate components should be warmed in hotwater up to a maximum temperature of 25 o C beforebeginning to mix. If heated to 25 o C, the subsequentlymixed material will need to be used more speedily as thepot life will be reduced to25 - 30 minutes. Alternatively,the material should be stored in an environmentcontrolled to 20 o C and only removed immediately beforeuse.APPLICATIONPatchfix Epoxy Binder should be applied as soon as themixing process has been completed. It should bebrushed, rolled or spray applied to the prepared surfaces.The new concrete or screed should be applied to thecoated substrate within 60 minutes at 20 o C.Where Patchfix Epoxy Binder is to be used as part of arepair system to form a substrate/repair barrier, careshould be taken to achieve an unbroken coating. Onecoat should be applied and allowed to gel (cure). Asecond coat should be applied and used as the bondingcoat. In some situations (e.g. sprayed concrete repairs) itmay be advantageous to scatter dust-free sharp sandover this coat and the concrete repair mortar should beapplied prior to the Patchfix Epoxy Binder fully curing(within 90minutes of Epoxy Binder application). As soonas the Patchfix Epoxy Binder has been applied, any<strong>PATCHFIX</strong> <strong>EPOXY</strong> <strong>BINDER</strong> PAGE 2 of 3.

equired steel reinforcement and/or formwork should beerected and fixed securely in place. Ensure the PatchfixEpoxy Binder is tacky prior to application of repair mortar.If the application of Epoxy Binder has cured and is touchdry, DO NOT apply cementitious repair mortar. Re-applywith a second coat of Patchfix Epoxy Binder to be the firstcoat and allow to reach a tacky consistency beforeapplying the cementitious repair mortar.Where Patchfix Epoxy Binder is to be used for groutingbolts or starter bars on horizontal surfaces then holediameter must be approximately 1.5 times the diameter ofthe actual bolt to be grouted. Set the bolt in the clean,contamination free hole and pour the mixed PatchfixEpoxy Binder from one side only, ensure that this isconducted in a continuous operation so as to avoid airentrapment and to ensure complete coverage around thebolt or starter bar. Patchfix Epoxy Binder may also beused as an Epoxy Binder to obtain a specific consistencywhen mixed with <strong>Bostik</strong> Patchfix Coarse/Fine Fillers(Refer to Technical Data Sheets on Patchfix Fillers).CLEAN-UPClean up uncured material and equipment immediatelyafter use using <strong>Bostik</strong> Solvent 9907. Do not use solventson skin. Cured Epoxy Binder is difficult to remove viachemical means and mechanical means may benecessary.PACKAGINGPatchfix Epoxy Binder is available in 2, 4 and 20 litre kits.COVERAGEOne litre will cover 1m 2 at 1mm thick. As an epoxybonding agent for new to old concrete the coverage rateis 4-5m 2 /litre.water (up to 25 o C) or stored in a temperaturecontrolled environment for 12 hours before use.These measures will facilitate mixing andapplication. Normal precautions for winter workingwith cementitious materials should then be adopted.• High temperature working: At ambient temperaturesabove 30 o C, the material should be stored in theshade or in an air-conditioned environment for12hours before use.• Do not dilute Epoxy Binder with solvents, as this willseverely affect the ultimate performance of theproduct.• Only mix as much Patchfix Epoxy Binder that canbe used within the pot life (25-25 minutes @ 25 o C).HEALTH AND SAFETYSome people are sensitive to epoxy resin. Gloves andprotective goggles must be worn during application anduse.• Avoid contact with the skin, eyes and avoidbreathing its vapour.• Wear protective gloves when mixing or using.• If poisoning occurs, contact a doctor.• If swallowed, Do Not induce vomiting. Give a glassof water.• If skin contact occurs, remove contaminatedclothing and wash skin thoroughly for a minimum of15 minutes.• If in eyes, hold eyes open, flood with water for atleast 15 minutes and see a doctor.• For more detailed information refer to the MaterialSafety Data Sheet.FIREPatchfix Epoxy Binder is non-flammableSTORAGEPatchfix Epoxy Binder has a shelf life of 12 months fromdate of manufacture when kept between 10 o C and 30ºCin a dry store in the original, unopened bags.All material shall be stored under cover in a manner thatwill prevent damage preferable on pallets and protectedfrom excessive heat and moisture. Do not freeze.PRECAUTION• Patchfix Epoxy Binder when mixed in large volumes,greater than 10 litres is highly likely to cure fasterreducing the pot life of the mixed material in the tin.• Low temperature working: the minimum applicationtemperature is 5 o C. In temperatures below 10 o C,the separate components should be heated in warmDisclaimer: The information detailed in this data sheet is liable tomodification from time to time in the light of experience and normalproduct application, and therefore customers are advised to check with<strong>Bostik</strong> Holding <strong>Hong</strong> <strong>Kong</strong> <strong>Limited</strong>, quoting the reference number thatthey possess the latest issue. The representations and recommendationsregarding the products are based on tests which we believe to be reliable.However, no guarantee of their accuracy can be made because of thegreat range of field conditions and variations encountered in raw materials,manufacturing equipment and methods. Thus, the products are sold witha limited warranty only, and on the condition that purchasers will maketheir own tests to determine the suitability of the product for their particularpurposes. Under no circumstances will <strong>Bostik</strong> Holding <strong>Hong</strong> <strong>Kong</strong> <strong>Limited</strong>be liable to anyone except for replacement of the products or refund of thepurchase price.<strong>Bostik</strong> Holding <strong>Hong</strong> <strong>Kong</strong> <strong>Limited</strong>6/F Victoria Centre15 Watson Road<strong>Hong</strong> <strong>Kong</strong>Tel: (852) 2807 9400Fax: (852) 2510 8380JAN/07/A<strong>PATCHFIX</strong> <strong>EPOXY</strong> <strong>BINDER</strong> PAGE 3 of 3.