Technical Data Sheet SEAL 'N' FLEX FC - Bostik Hong Kong Limited

Technical Data Sheet SEAL 'N' FLEX FC - Bostik Hong Kong Limited

Technical Data Sheet SEAL 'N' FLEX FC - Bostik Hong Kong Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

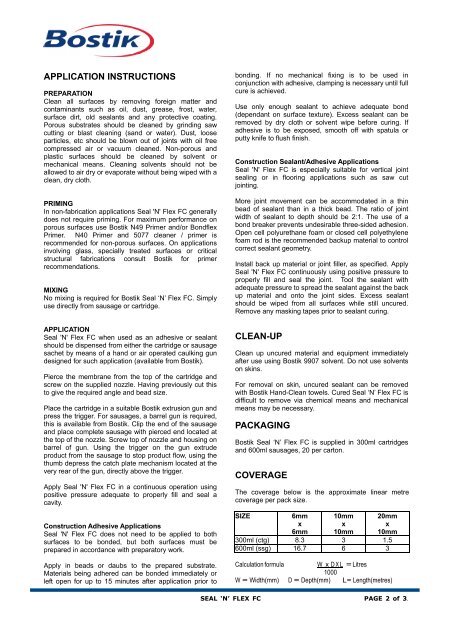

APPLICATION INSTRUCTIONSPREPARATIONClean all surfaces by removing foreign matter andcontaminants such as oil, dust, grease, frost, water,surface dirt, old sealants and any protective coating.Porous substrates should be cleaned by grinding sawcutting or blast cleaning (sand or water). Dust, looseparticles, etc should be blown out of joints with oil freecompressed air or vacuum cleaned. Non-porous andplastic surfaces should be cleaned by solvent ormechanical means. Cleaning solvents should not beallowed to air dry or evaporate without being wiped with aclean, dry cloth.PRIMINGIn non-fabrication applications Seal <strong>'N'</strong> Flex <strong>FC</strong> generallydoes not require priming. For maximum performance onporous surfaces use <strong>Bostik</strong> N49 Primer and/or BondflexPrimer. N40 Primer and 5077 cleaner / primer isrecommended for non-porous surfaces. On applicationsinvolving glass, specially treated surfaces or criticalstructural fabrications consult <strong>Bostik</strong> for primerrecommendations.MIXINGNo mixing is required for <strong>Bostik</strong> Seal ‘N’ Flex <strong>FC</strong>. Simplyuse directly from sausage or cartridge.APPLICATIONSeal <strong>'N'</strong> Flex <strong>FC</strong> when used as an adhesive or sealantshould be dispensed from either the cartridge or sausagesachet by means of a hand or air operated caulking gundesigned for such application (available from <strong>Bostik</strong>).Pierce the membrane from the top of the cartridge andscrew on the supplied nozzle. Having previously cut thisto give the required angle and bead size.Place the cartridge in a suitable <strong>Bostik</strong> extrusion gun andpress the trigger. For sausages, a barrel gun is required,this is available from <strong>Bostik</strong>. Clip the end of the sausageand place complete sausage with pierced end located atthe top of the nozzle. Screw top of nozzle and housing onbarrel of gun. Using the trigger on the gun extrudeproduct from the sausage to stop product flow, using thethumb depress the catch plate mechanism located at thevery rear of the gun, directly above the trigger.Apply Seal <strong>'N'</strong> Flex <strong>FC</strong> in a continuous operation usingpositive pressure adequate to properly fill and seal acavity.Construction Adhesive ApplicationsSeal <strong>'N'</strong> Flex <strong>FC</strong> does not need to be applied to bothsurfaces to be bonded, but both surfaces must beprepared in accordance with preparatory work.Apply in beads or daubs to the prepared substrate.Materials being adhered can be bonded immediately orleft open for up to 15 minutes after application prior tobonding. If no mechanical fixing is to be used inconjunction with adhesive, clamping is necessary until fullcure is achieved.Use only enough sealant to achieve adequate bond(dependant on surface texture). Excess sealant can beremoved by dry cloth or solvent wipe before curing. Ifadhesive is to be exposed, smooth off with spatula orputty knife to flush finish.Construction Sealant/Adhesive ApplicationsSeal <strong>'N'</strong> Flex <strong>FC</strong> is especially suitable for vertical jointsealing or in flooring applications such as saw cutjointing.More joint movement can be accommodated in a thinbead of sealant than in a thick bead. The ratio of jointwidth of sealant to depth should be 2:1. The use of abond breaker prevents undesirable three-sided adhesion.Open cell polyurethane foam or closed cell polyethylenefoam rod is the recommended backup material to controlcorrect sealant geometry.Install back up material or joint filler, as specified. ApplySeal <strong>'N'</strong> Flex <strong>FC</strong> continuously using positive pressure toproperly fill and seal the joint. Tool the sealant withadequate pressure to spread the sealant against the backup material and onto the joint sides. Excess sealantshould be wiped from all surfaces while still uncured.Remove any masking tapes prior to sealant curing.CLEAN-UPClean up uncured material and equipment immediatelyafter use using <strong>Bostik</strong> 9907 solvent. Do not use solventson skins.For removal on skin, uncured sealant can be removedwith <strong>Bostik</strong> Hand-Clean towels. Cured Seal ‘N’ Flex <strong>FC</strong> isdifficult to remove via chemical means and mechanicalmeans may be necessary.PACKAGING<strong>Bostik</strong> Seal ‘N’ Flex <strong>FC</strong> is supplied in 300ml cartridgesand 600ml sausages, 20 per carton.COVERAGEThe coverage below is the approximate linear metrecoverage per pack size.SIZE6mmx6mm10mmx10mm20mmx10mm300ml (ctg) 8.3 3 1.5600ml (ssg) 16.7 6 3Calculation formulaW x D X L = Litres1000W = Width(mm) D = Depth(mm) L= Length(metres)<strong>SEAL</strong> ‘N’ <strong>FLEX</strong> <strong>FC</strong> PAGE 2 of 3.