and Printing

Super Fibers - A. Venturi

Super Fibers - A. Venturi

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

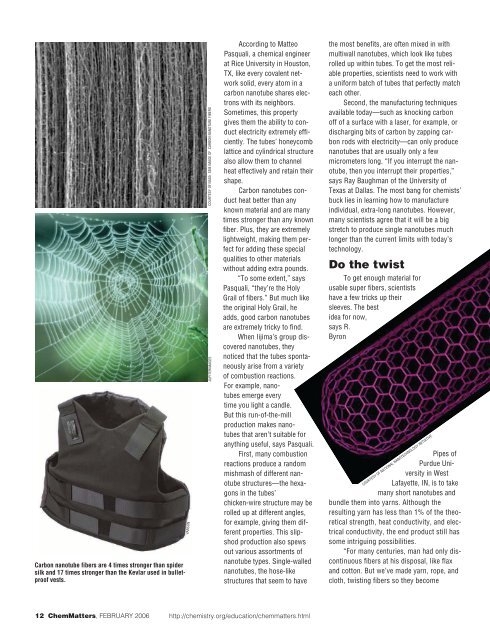

Carbon nanotube fibers are 4 times stronger than spidersilk <strong>and</strong> 17 times stronger than the Kevlar used in bulletproofvests.VANSONCOURTESY OF NASA SEM IMAGE OF CARBON NANOTUBE FIBERSJUPITERIMAGESAccording to MatteoPasquali, a chemical engineerat Rice University in Houston,TX, like every covalent networksolid, every atom in acarbon nanotube shares electronswith its neighbors.Sometimes, this propertygives them the ability to conductelectricity extremely efficiently.The tubes’ honeycomblattice <strong>and</strong> cylindrical structurealso allow them to channelheat effectively <strong>and</strong> retain theirshape.Carbon nanotubes conductheat better than anyknown material <strong>and</strong> are manytimes stronger than any knownfiber. Plus, they are extremelylightweight, making them perfectfor adding these specialqualities to other materialswithout adding extra pounds.“To some extent,” saysPasquali, “they’re the HolyGrail of fibers.” But much likethe original Holy Grail, headds, good carbon nanotubesare extremely tricky to find.When Iijima’s group discoverednanotubes, theynoticed that the tubes spontaneouslyarise from a varietyof combustion reactions.For example, nanotubesemerge everytime you light a c<strong>and</strong>le.But this run-of-the-millproduction makes nanotubesthat aren’t suitable foranything useful, says Pasquali.First, many combustionreactions produce a r<strong>and</strong>ommishmash of different nanotubestructures—the hexagonsin the tubes’chicken-wire structure may berolled up at different angles,for example, giving them differentproperties. This slipshodproduction also spewsout various assortments ofnanotube types. Single-wallednanotubes, the hose-likestructures that seem to havethe most benefits, are often mixed in withmultiwall nanotubes, which look like tubesrolled up within tubes. To get the most reliableproperties, scientists need to work witha uniform batch of tubes that perfectly matcheach other.Second, the manufacturing techniquesavailable today—such as knocking carbonoff of a surface with a laser, for example, ordischarging bits of carbon by zapping carbonrods with electricity—can only producenanotubes that are usually only a fewmicrometers long. “If you interrupt the nanotube,then you interrupt their properties,”says Ray Baughman of the University ofTexas at Dallas. The most bang for chemists’buck lies in learning how to manufactureindividual, extra-long nanotubes. However,many scientists agree that it will be a bigstretch to produce single nanotubes muchlonger than the current limits with today’stechnology.Do the twistTo get enough material forusable super fibers, scientistshave a few tricks up theirsleeves. The bestidea for now,says R.ByronPipes ofPurdue Universityin WestLafayette, IN, is to takemany short nanotubes <strong>and</strong>bundle them into yarns. Although theresulting yarn has less than 1% of the theoreticalstrength, heat conductivity, <strong>and</strong> electricalconductivity, the end product still hassome intriguing possibilities.“For many centuries, man had only discontinuousfibers at his disposal, like flax<strong>and</strong> cotton. But we’ve made yarn, rope, <strong>and</strong>cloth, twisting fibers so they becomeCOURTESY OF NATIONAL NANOTECHNOLOGY INITIATIVE12 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html