HARDWARE

05 - Hard ware - Bullivants

05 - Hard ware - Bullivants

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Wire Rope Terminations<br />

Wedge Sockets<br />

Wedge - type sockets are used in lifting, pulling, tensioning and staying systems as a simple mechanical connection to steel wire<br />

ropes, especially where steel wire ropes may require shortening. One end of the wedge type socket is able to clamp a rope with a<br />

wedging action and the other end is able to connect to another fitting or anchorage.<br />

The wedge - type socket is designed for use on wire ropes up to and including 1770 grade wire with a wire rope core, however<br />

higher grade wire rope may be used, provided it meets the intent of this Standard.<br />

Metal or Spelter Sockets - Open and Closed<br />

The load is transferred between the rope and the socket forging or casting by means of adhesion between the rope wires and<br />

the metal or resin used in the socket bowl and subsequent wedging action provided by the bond between the rope’s wires and<br />

the metal or resin in the socket. Care should be taken to follow the correct socketing procedure. Properly applied poured socket<br />

attachments will withstand the actual breaking force of the wire rope.<br />

Sockets<br />

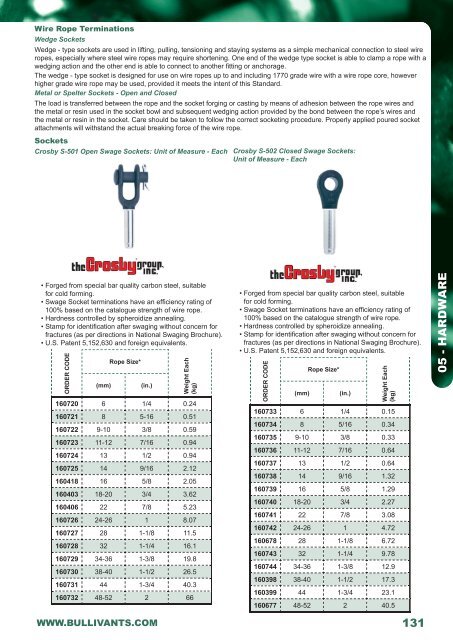

Crosby S-501 Open Swage Sockets: Unit of Measure - Each<br />

Crosby S-502 Closed Swage Sockets:<br />

Unit of Measure - Each<br />

• Forged from special bar quality carbon steel, suitable<br />

for cold forming.<br />

• Swage Socket terminations have an effi ciency rating of<br />

100% based on the catalogue strength of wire rope.<br />

• Hardness controlled by spheroidize annealing.<br />

• Stamp for identification after swaging without concern for<br />

fractures (as per directions in National Swaging Brochure).<br />

• U.S. Patent 5,152,630 and foreign equivalents.<br />

ORDER CODE<br />

(mm)<br />

Rope Size*<br />

(in.)<br />

Weight Each<br />

(kg)<br />

160720 6 1/4 0.24<br />

160721 8 5-16 0.51<br />

160722 9-10 3/8 0.59<br />

160723 11-12 7/16 0.94<br />

160724 13 1/2 0.94<br />

160725 14 9/16 2.12<br />

160418 16 5/8 2.05<br />

160403 18-20 3/4 3.62<br />

160406 22 7/8 5.23<br />

160726 24-26 1 8.07<br />

160727 28 1-1/8 11.5<br />

160728 32 1-1/4 16.1<br />

160729 34-36 1-3/8 19.8<br />

160730 38-40 1-1/2 26.5<br />

160731 44 1-3/4 40.3<br />

160732 48-52 2 66<br />

• Forged from special bar quality carbon steel, suitable<br />

for cold forming.<br />

• Swage Socket terminations have an efficiency rating of<br />

100% based on the catalogue strength of wire rope.<br />

• Hardness controlled by spheroidize annealing.<br />

• Stamp for identification after swaging without concern for<br />

fractures (as per directions in National Swaging Brochure).<br />

• U.S. Patent 5,152,630 and foreign equivalents.<br />

ORDER CODE<br />

(mm)<br />

Rope Size*<br />

(in.)<br />

Weight Each<br />

(kg)<br />

160733 6 1/4 0.15<br />

160734 8 5/16 0.34<br />

160735 9-10 3/8 0.33<br />

160736 11-12 7/16 0.64<br />

160737 13 1/2 0.64<br />

160738 14 9/16 1.32<br />

160739 16 5/8 1.29<br />

160740 18-20 3/4 2.27<br />

160741 22 7/8 3.08<br />

160742 24-26 1 4.72<br />

160678 28 1-1/8 6.72<br />

160743 32 1-1/4 9.78<br />

160744 34-36 1-3/8 12.9<br />

160398 38-40 1-1/2 17.3<br />

160399 44 1-3/4 23.1<br />

160677 48-52 2 40.5<br />

05 - <strong>HARDWARE</strong><br />

WWW.BULLIVANTS.COM 131