HARDWARE

05 - Hard ware - Bullivants

05 - Hard ware - Bullivants

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

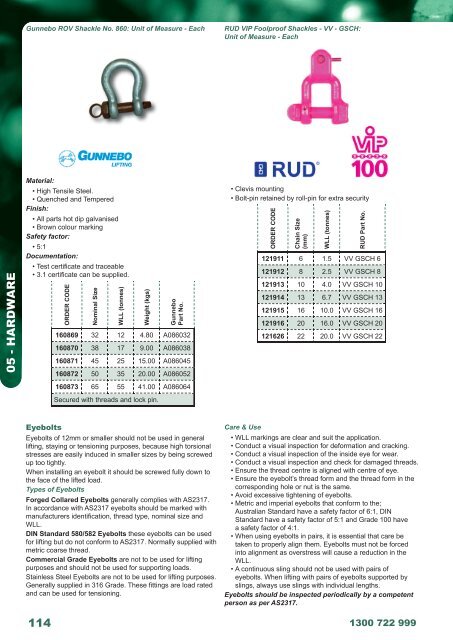

Gunnebo ROV Shackle No. 860: Unit of Measure - Each<br />

RUD VIP Foolproof Shackles - VV - GSCH:<br />

Unit of Measure - Each<br />

05 - <strong>HARDWARE</strong><br />

Material:<br />

• High Tensile Steel.<br />

• Quenched and Tempered<br />

Finish:<br />

• All parts hot dip galvanised<br />

• Brown colour marking<br />

Safety factor:<br />

• 5:1<br />

Documentation:<br />

• Test certificate and traceable<br />

• 3.1 certificate can be supplied.<br />

ORDER CODE<br />

Nominal Size<br />

WLL (tonnes)<br />

Weight (kgs)<br />

Gunnebo<br />

Part No.<br />

160869 32 12 4.80 A086032<br />

160870 38 17 9.00 A086038<br />

160871 45 25 15.00 A086045<br />

160872 50 35 20.00 A086052<br />

• Clevis mounting<br />

• Bolt-pin retained by roll-pin for extra security<br />

ORDER CODE<br />

Chain Size<br />

(mm)<br />

WLL (tonnes)<br />

RUD Part No.<br />

121911 6 1.5 VV GSCH 6<br />

121912 8 2.5 VV GSCH 8<br />

121913 10 4.0 VV GSCH 10<br />

121914 13 6.7 VV GSCH 13<br />

121915 16 10.0 VV GSCH 16<br />

121916 20 16.0 VV GSCH 20<br />

121626 22 20.0 VV GSCH 22<br />

160873 65 55 41.00 A086064<br />

Secured with threads and lock pin.<br />

Eyebolts<br />

Eyebolts of 12mm or smaller should not be used in general<br />

lifting, staying or tensioning purposes, because high torsional<br />

stresses are easily induced in smaller sizes by being screwed<br />

up too tightly.<br />

When installing an eyebolt it should be screwed fully down to<br />

the face of the lifted load.<br />

Types of Eyebolts<br />

Forged Collared Eyebolts generally complies with AS2317.<br />

In accordance with AS2317 eyebolts should be marked with<br />

manufacturers identifi cation, thread type, nominal size and<br />

WLL.<br />

DIN Standard 580/582 Eyebolts these eyebolts can be used<br />

for lifting but do not conform to AS2317. Normally supplied with<br />

metric coarse thread.<br />

Commercial Grade Eyebolts are not to be used for lifting<br />

purposes and should not be used for supporting loads.<br />

Stainless Steel Eyebolts are not to be used for lifting purposes.<br />

Generally supplied in 316 Grade. These fittings are load rated<br />

and can be used for tensioning.<br />

114<br />

Care & Use<br />

• WLL markings are clear and suit the application.<br />

• Conduct a visual inspection for deformation and cracking.<br />

• Conduct a visual inspection of the inside eye for wear.<br />

• Conduct a visual inspection and check for damaged threads.<br />

• Ensure the thread centre is aligned with centre of eye.<br />

• Ensure the eyebolt’s thread form and the thread form in the<br />

corresponding hole or nut is the same.<br />

• Avoid excessive tightening of eyebolts.<br />

• Metric and imperial eyebolts that conform to the;<br />

Australian Standard have a safety factor of 6:1, DIN<br />

Standard have a safety factor of 5:1 and Grade 100 have<br />

a safety factor of 4:1.<br />

• When using eyebolts in pairs, it is essential that care be<br />

taken to properly align them. Eyebolts must not be forced<br />

into alignment as overstress will cause a reduction in the<br />

WLL.<br />

• A continuous sling should not be used with pairs of<br />

eyebolts. When lifting with pairs of eyebolts supported by<br />

slings, always use slings with individual lengths.<br />

Eyebolts should be inspected periodically by a competent<br />

person as per AS2317.<br />

1300 722 999