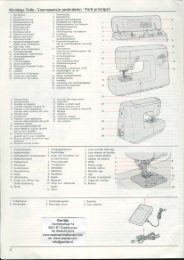

PFAFF

PFAFF234 - Gerrijts

PFAFF234 - Gerrijts

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R 5315<br />

i-n I<br />

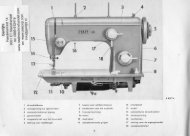

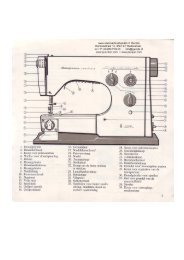

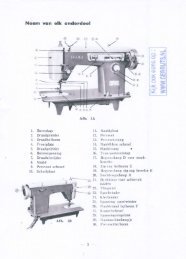

<strong>PFAFF</strong> 234<br />

High-Speed Sewing Machine<br />

INSTRUCTION BOOK

Fis.20<br />

R 5090<br />

/. Hold the bolonce wheel in this position ond turn lhe hook on its shoft<br />

until its point is opposite the center line of rhe needle. Slightly tighten<br />

whicheveÍ hook sel screw con be reoched mosl eosily.<br />

L Check whether the hook point is obout 3ir." (1.2 mm) obove ihe rop<br />

of the needle eye. If odiusiment is required, loosen set screw c (Fig, l9)<br />

ond set fhe needle bor ot ihe correct height.<br />

9. Check whether lhere is o cleoronce of .004" (0.1mm) belween lhe hook<br />

point ond lhe needle. Moke sure thot the hook point will never choíe<br />

ogoinst lhe needle.<br />

10. Tighleo boih hook sel scíews<br />

pres5er Íoot.<br />

sêcurely ond reploce needle plole ond<br />

To focilitote setting the needle bor ot the coírect height, o smoll depression<br />

obout t/e." wide hos been milled into the bor. When the needle bor<br />

hos reoched the lowest point of its siroke, the top of this mork shoulo oe<br />

Ílush with the boitom edge of the lower needle bor bushing. The width of<br />

lhis mork coincides with ihe omount of needle rise reouired lo Íorm<br />

the loop. In other words, when the needle bor hos risen obout 5/r." Írom<br />

the lowesl point of its ltrole, the hook point should be opposite lhe centeí<br />

line of the needle.<br />

This lost odjustment pÍocedure, however, is not prêcise enough.

Inslruclions Íor Mechanics<br />

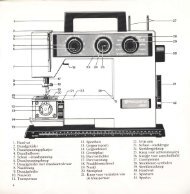

17, The V-Beh Drive<br />

When mounling the V.beli for the first time, core should be token thof il<br />

rs nol forced on the motoí pulley becouse o crookedly mounied belt weors<br />

out ouicklv.<br />

Íhe vorious moto.s used lo drive ihe PioÍ.23.i cre siondord molors con.<br />

lorming to Germon DIN 42ó91 speciíico'ons. ïhey ore pivotolly connected<br />

wilh lhe motor brockei by meons oÍ c h n_qe s:ud ond. oíier loosening o<br />

sel screw or nul, con be swung to ony des ea cos i on to focilitote mounr.<br />

ing lhe bell on lhe mochine ond moto- c- ers See io:or picr.rrec n<br />

Fio. I7l<br />

Fig l7<br />

The tension musl noi be set ioo tight os thrs would couse excessrve pressure<br />

on lhe orm shoft beorings ond might result in overheoting ond seizing oÍ<br />

lhe mochine.<br />

The bell is lens oned corrcclly ií you con cornpfess il obout i! oÍ on inch<br />

midwoy belween both pulleys.<br />

Tighten the h nge siud nul (or set screw k on moiors<br />

so lhol il will no; loosen while sewing.<br />

Fig. l7) securely<br />

18

Fig.6<br />

R 4345<br />

8. Choosing the Proper Needle<br />

The Píoff 234 uses the Íollowing round-shonk, round-poini needles:<br />

Model A System 134 nêedtes<br />

Model B - System l3J needtes<br />

Model C Sysïêm 134 needles<br />

Necdle ond lhreod Chort<br />

Needle Size Corlon s itk Synthetic Lrnen<br />

6l<br />

t30 3<br />

130i,1<br />

1403<br />

200i 3 I50/3<br />

:l<br />

r 00.,3<br />

100,I<br />

120r3<br />

140'3 - r 2c 3<br />

BO<br />

80/3<br />

80'4<br />

100/3<br />

I 20/3 - 1003<br />

90<br />

70/3 -ó0i3<br />

70t4-ó0,'4<br />

80/3<br />

r00/3- 80,'3<br />

70t3<br />

't00<br />

50t3 - 40/3<br />

5A/4 - 40/4<br />

70/3<br />

70/3<br />

60/3<br />

0<br />

3Cr/3<br />

30/4<br />

30ió<br />

60/3<br />

ó0l3<br />

50/3

Oil seoler screw 2 (Fig. l) on the top covoí hos two oilwicks qttoched fo<br />

it whió providê for on odditionol lubricotion of the feed eccentric ono,<br />

therefore, should be sooked with oil thoroughly. Both the verticol shofr rop<br />

beoring ond the upper bevel geor ossembly con b6 oiled qÍter tqking out<br />

cop screw 3 (Fig, 1). The needle bor is lubricoted by meons oÍ on oilwick<br />

which leods down Írom the tqke-up guord ond is jooked with sproy oil.<br />

Form lhe. hobii oÍ pufting o drop oÍ oil into the hook rocewoy severol<br />

lrmes o cloy.<br />

Cerloin. sewing .lroubles, such os lhreod breoking ond stitó skipping,<br />

connol be remedied by opplying excessive quonlities of oil. Excess oil qno<br />

lint tend lo form o pocked moss which, in time, will couse hord running oÍ<br />

ihe moóine ond soiling of the work.<br />

Mokr it o rulc, thereÍore, to qpply oil rporingly but regulorly.<br />

Alwoys use PfofÍ sewing mochine oil No.28GllmI22<br />

non-resinous.<br />

whió is completely<br />

Although the bevel geors ore enclosed in coses ond require no speciol moinlenonce,<br />

il is recommended to reploce the old greose by Pfoff greose No.<br />

2&-l-12O 213 once o yeor. Owing fo the speciol Ébricoting propeities of this<br />

greose, the flonks of the bevel geor teeih should be greoled only lightly.<br />

From lime to iime, unscrew the needle plote ond remove lhe lint which<br />

hos occumuloted on the Íeed dog ond in the viciniry oÍ the sewing hook.<br />

This ir very impo.tont becouse this lint contoins smoil porticles of dressing<br />

which couse excessive weor of the sewing meóonism. On moclrines which<br />

oÍe in opeÍolion constontly, the lini musl be removed every doy.<br />

5, lemoving the Bobbin Cose<br />

Roise the toke-up lever to its highest position ond open the bed slide. Reocn<br />

under lhe toble wiih your left hond ond open the bobbin cole loích with<br />

the noil of your thumb. Pull out the bobbin cose by holding rhe lotch with<br />

thumb ond ÍoreÍinger, os shown in Fig.4. While you hold the bobbin cose<br />

by its open lotch, the bobbin connot foll out.<br />

6. Winding rhe Bobbin<br />

Bobbins ore wound wilh lhe power-driven bobbin winder (Fig.5), which<br />

requires no lub.icotion since its spindle runs in q sinlered steel bushing.<br />

A bofÍle plote mounled on the winder bose prevents the lhreod from berng<br />

pulled loword the driving belt by ihe droÍt of oi. cqused by the belr. Thé<br />

V-groove in the rim of lhe winder pulley hos on obtuse-ongled profile which<br />

permih lhe use of both round ond V-belts.