DIMENSIONS

DIMENSIONS & PROPERTIES - Steel & Tube

DIMENSIONS & PROPERTIES - Steel & Tube

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Coil<br />

COIL<br />

products<br />

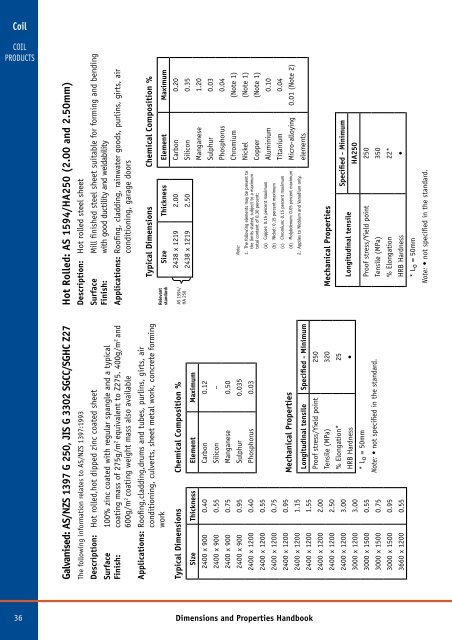

Galvanised: AS/NZS 1397 G 250, Jis G 3302 SGcc/SGHC Z27<br />

The following information relates to AS/NZS 1397:1993<br />

Hot Rolled: AS 1594/HA250 (2.00 and 2.50mm)<br />

Description: Hot rolled,hot dipped zinc coated sheet<br />

Description: Hot rolled steel sheet<br />

Surface 100% zinc coated with regular spangle and a typical<br />

Finish: coating mass of 275g/m 2 equivalent to Z275. 400g/m 2 and<br />

600g/m 2 coating weight mass also available<br />

Applications: Roofing,cladding,drums and tubes, purlins, girts, air<br />

conditioning, culverts, sheet metal work, concrete forming<br />

work<br />

Typical Dimensions<br />

Chemical Composition %<br />

Surface Mill finished steel sheet suitable for forming and bending<br />

Finish: with good ductility and weldability<br />

Applications: Roofing, cladding, rainwater goods, purlins, girts, air<br />

conditioning, garage doors<br />

Chemical Composition %<br />

Typical Dimensions<br />

Element Maximum<br />

Size Thickness<br />

Relevant<br />

standard:<br />

Size Thickness<br />

2400 x 900 0.40<br />

2400 x 900 0.55<br />

2400 x 900 0.75<br />

2400 x 900 0.95<br />

2400 x 1200 0.40<br />

2400 x 1200 0.55<br />

2400 x 1200 0.75<br />

2400 x 1200 0.95<br />

2400 x 1200 1.15<br />

2400 x 1200 1.55<br />

2400 x 1200 2.00<br />

2400 x 1200 2.50<br />

2400 x 1200 3.00<br />

3000 x 1200 3.00<br />

3000 x 1500 0.55<br />

3000 x 1500 0.75<br />

3000 x 1500 0.95<br />

3660 x 1200 0.55<br />

Element Maximum<br />

Carbon 0.12<br />

Silicon –<br />

Manganese 0.50<br />

Sulphur 0.035<br />

Phosphorus 0.03<br />

Mechanical Properties<br />

Longitudinal tensile Specified - Minimum<br />

Proof stress/Yield point 250<br />

Tensile (MPa) 320<br />

% Elongation* 25<br />

HRB Hardness •<br />

* Lo = 50mm<br />

Note: • not specified in the standard.<br />

Carbon 0.20<br />

Silicon 0.35<br />

2438 x 1219 2.00<br />

2438 x 1219 2.50<br />

AS 1594/<br />

HA 250<br />

Manganese 1.20<br />

Sulphur 0.03<br />

Phosphorus 0.04<br />

Chromium (Note 1)<br />

Nickel (Note 1)<br />

Copper (Note 1)<br />

Aluminium 0.10<br />

Titanium 0.04<br />

Micro-alloying 0.01 (Note 2)<br />

elements<br />

Note:<br />

1. The following elements may be present to<br />

the limits stated, subject to a maximum<br />

total content of 0.30 percent:<br />

(a) Copper: 0.15 percent maximum<br />

(b) Nickel: 0.15 percent maximum<br />

(c) Chromium: 0.15 percent maximum<br />

(d) Molybdenum: 0.05 percent maximum<br />

2. Applies to Niobium and Vanadium only.<br />

Mechanical Properties<br />

Specified - Minimum<br />

Longitudinal tensile<br />

HA250<br />

Proof stress/Yield point 250<br />

Tensile (MPa) 350<br />

% Elongation 22*<br />

HRB Hardness •<br />

* Lo = 50mm<br />

Note: • not specified in the standard.<br />

36<br />

Dimensions and Properties Handbook