DIMENSIONS

DIMENSIONS & PROPERTIES - Steel & Tube

DIMENSIONS & PROPERTIES - Steel & Tube

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

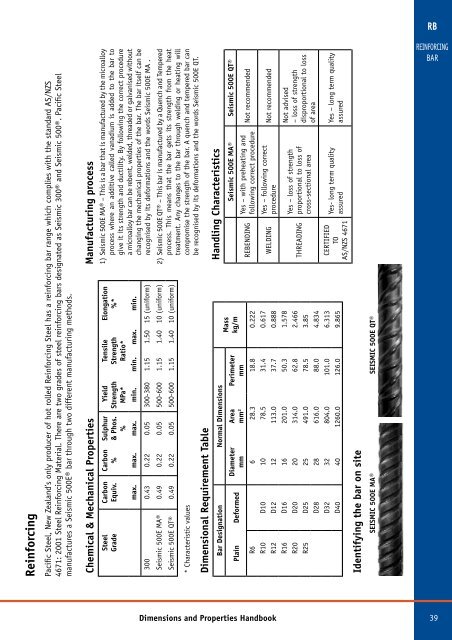

Reinforcing<br />

Pacific Steel, New Zealand’s only producer of hot rolled Reinforcing Steel has a reinforcing bar range which complies with the standard AS/NZS<br />

4671: 2001 Steel Reinforcing Material. There are two grades of steel reinforcing bars designated as Seismic 300® and Seismic 500®. Pacific Steel<br />

manufactures a Seismic 500E® bar through two different manufacturing methods.<br />

Manufacturing process<br />

Chemical & Mechanical Properties<br />

1) Seismic 500E MA® – This is a bar that is manufactured by the microalloy<br />

process where an additive called vanadium is added to the bar to<br />

give it its strength and ductility. By following the correct procedure<br />

a microalloy bar can be rebent, welded, threaded or galvanised without<br />

changing the mechanical properties of the bar. The bar itself can be<br />

recognised by its deformations and the words Seismic 500E MA .<br />

Elongation<br />

%*<br />

Tensile<br />

Strength<br />

Ratio*<br />

Yield<br />

Strength<br />

MPa*<br />

Sulphur<br />

& Phos.<br />

%<br />

Carbon<br />

%<br />

Carbon<br />

Equiv.<br />

Steel<br />

Grade<br />

max. max. max. min. min. max. min.<br />

300 0.43 0.22 0.05 300-380 1.15 1.50 15 (uniform)<br />

2) Seismic 500E QT® – This bar is manufactured by a Quench and Tempered<br />

process. This means that the bar gets its strength from the heat<br />

treatment. Any changes to the bar through welding or heating will<br />

compromise the strength of the bar. A quench and tempered bar can<br />

be recognised by its deformations and the words Seismic 500E QT.<br />

Seismic 500E MA® 0.49 0.22 0.05 500-600 1.15 1.40 10 (uniform)<br />

Seismic 500E QT® 0.49 0.22 0.05 500-600 1.15 1.40 10 (uniform)<br />

* Characteristic values<br />

Dimensional Requirement Table<br />

Handling Characteristics<br />

Bar Designation Normal Dimensions<br />

Seismic 500E MA® Seismic 500E QT®<br />

Mass<br />

kg/m<br />

Area Perimeter<br />

mm 2 mm<br />

Diameter<br />

mm<br />

Plain Deformed<br />

Not recommended<br />

Yes – with preheating and<br />

following correct procedure<br />

REBENDING<br />

Not recommended<br />

Yes – following correct<br />

procedure<br />

WELDING<br />

Not advised<br />

– loss of strength<br />

disproportional to loss<br />

of area<br />

Yes – loss of strength<br />

proportional to loss of<br />

cross-sectional area<br />

THREADING<br />

Yes – long term quality<br />

assured<br />

Yes- long term quality<br />

assured<br />

CERTIFIED<br />

TO<br />

AS/NZS 4671<br />

R6 6 28.3 18.8 0.222<br />

R10 D10 10 78.5 31.4 0.617<br />

R12 D12 12 113.0 37.7 0.888<br />

R16 D16 16 201.0 50.3 1.578<br />

R20 D20 20 314.0 62.8 2.466<br />

R25 D25 25 491.0 78.5 3.85<br />

D28 28 616.0 88.0 4.834<br />

D32 32 804.0 101.0 6.313<br />

D40 40 1260.0 126.0 9.865<br />

Identifying the bar on site<br />

Seismic 500E QT®<br />

Seismic 500E MA®<br />

RB<br />

REINFORCING<br />

BAR<br />

Dimensions and Properties Handbook 39