DIMENSIONS

DIMENSIONS & PROPERTIES - Steel & Tube

DIMENSIONS & PROPERTIES - Steel & Tube

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

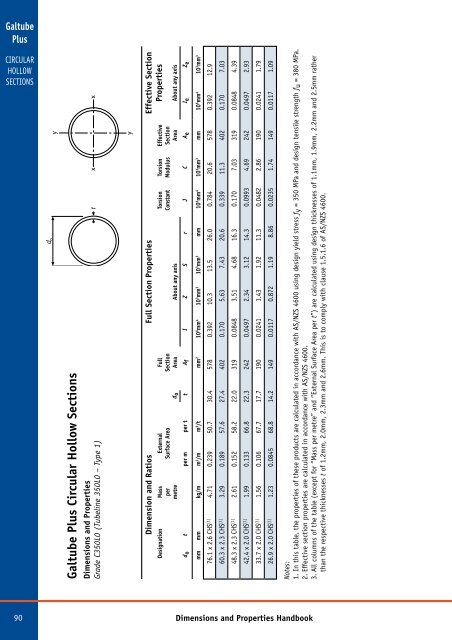

Galtube<br />

Plus<br />

Circular<br />

hollow<br />

sections<br />

y<br />

o<br />

x<br />

x<br />

Galtube Plus Circular Hollow Sections<br />

Dimensions and Properties<br />

Grade C350L0 (Tubeline 350L0 – Type 1)<br />

y<br />

Dimension and Ratios Full Section Properties Effective Section<br />

Properties<br />

Effective<br />

Section<br />

Area<br />

Torsion<br />

Modulus<br />

Torsion<br />

Constant<br />

Full<br />

Section<br />

Area About any axis<br />

External<br />

Surface Area<br />

Designation Mass<br />

per<br />

metre<br />

d o About any axis<br />

d o t per m per t t A f I Z S r J C A e I e Z e<br />

mm mm kg/m m 2 /m m 2 /t mm 2 10 6 mm 4 10 3 mm 3 10 3 mm 3 mm 10 6 mm 4 10 3 mm 3 mm 10 6 mm 4 10 3 mm 3<br />

76.1 x 2.6 CHS (1) 4.71 0.239 50.7 30.4 578 0.392 10.3 13.5 26.0 0.784 20.6 578 0.392 12.9<br />

60.3 x 2.3 CHS (1) 3.29 0.189 57.6 27.4 402 0.170 5.63 7.43 20.6 0.339 11.3 402 0.170 7.03<br />

48.3 x 2.3 CHS (1) 2.61 0.152 58.2 22.0 319 0.0848 3.51 4.68 16.3 0.170 7.03 319 0.0848 4.39<br />

42.4 x 2.0 CHS (1) 1.99 0.133 66.8 22.3 242 0.0497 2.34 3.12 14.3 0.0993 4.69 242 0.0497 2.93<br />

33.7 x 2.0 CHS (1) 1.56 0.106 67.7 17.7 190 0.0241 1.43 1.92 11.3 0.0482 2.86 190 0.0241 1.79<br />

26.9 x 2.0 CHS (1) 1.23 0.0845 68.8 14.2 149 0.0117 0.872 1.19 8.86 0.0235 1.74 149 0.0117 1.09<br />

Notes:<br />

1. In this table, the properties of these products are calculated in accordance with AS/NZS 4600 using design yield stress fy = 350 MPa and design tensile strength fu = 380 MPa.<br />

2. Effective section properties are calculated in accordance with AS/NZS 4600.<br />

3. All columns of the table (except for “Mass per metre” and “External Surface Area per t”) are calculated using design thicknesses of 1.1mm, 1.9mm, 2.2mm and 2.5mm rather<br />

than the respective thicknesses t of 1.2mm, 2.0mm, 2.3mm and 2.6mm. This is to comply with clause 1.5.1.6 of AS/NZS 4600.<br />

90<br />

Dimensions and Properties Handbook