DIMENSIONS

DIMENSIONS & PROPERTIES - Steel & Tube

DIMENSIONS & PROPERTIES - Steel & Tube

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

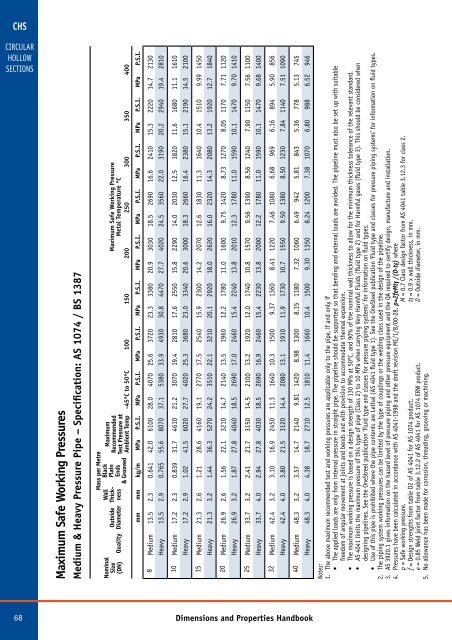

CHS<br />

Circular<br />

hollow<br />

sections<br />

Maximum Safe Working Pressures<br />

Medium & Heavy Pressure Pipe – Specification: AS 1074 / BS 1387<br />

Maximum Safe Working Pressure<br />

Metal Temperature ºC<br />

-45ºC to 50ºC 100 150 200 250 300 350 400<br />

Maximum<br />

Recommended<br />

Test Pressure at<br />

Ambient Temp<br />

Mass per Metre<br />

Black<br />

Plain<br />

Ends<br />

& Grooved<br />

Wall<br />

Thickness<br />

Nominal<br />

Size<br />

Outside<br />

(DN) Quality Diameter<br />

Outside<br />

mm mm kg/m MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I. MPa P.S.I.<br />

2130<br />

2810<br />

14.7<br />

19.4<br />

2220<br />

2940<br />

15.3<br />

20.2<br />

2410<br />

3190<br />

16.6<br />

22.0<br />

2690<br />

3560<br />

18.5<br />

24.5<br />

3030<br />

4020<br />

20.9<br />

27.7<br />

3380<br />

4470<br />

23.3<br />

30.8<br />

3720<br />

4930<br />

25.6<br />

33.9<br />

4070<br />

5380<br />

28.0<br />

37.1<br />

6100<br />

8070<br />

42.0<br />

55.6<br />

0.641<br />

0.765<br />

2.3<br />

2.9<br />

13.5<br />

13.5<br />

8 Medium<br />

Heavy<br />

1610<br />

2100<br />

11.1<br />

14.5<br />

1680<br />

2190<br />

11.6<br />

15.1<br />

1820<br />

2380<br />

12.5<br />

16.4<br />

2030<br />

2660<br />

14.0<br />

18.3<br />

2290<br />

3000<br />

15.8<br />

20.6<br />

2550<br />

3340<br />

17.6<br />

23.0<br />

2810<br />

3680<br />

19.4<br />

25.3<br />

3070<br />

4020<br />

21.2<br />

27.7<br />

4610<br />

6020<br />

31.7<br />

41.5<br />

0.839<br />

1.02<br />

2.3<br />

2.9<br />

17.2<br />

17.2<br />

10 Medium<br />

Heavy<br />

1450<br />

1840<br />

9.99<br />

12.7<br />

1510<br />

1920<br />

10.4<br />

13.2<br />

1640<br />

2080<br />

11.3<br />

14.3<br />

1830<br />

2320<br />

12.6<br />

16.0<br />

2070<br />

2620<br />

14.2<br />

18.0<br />

2300<br />

2920<br />

15.9<br />

20.1<br />

2540<br />

3210<br />

17.5<br />

22.1<br />

2770<br />

3510<br />

19.1<br />

24.2<br />

4160<br />

5270<br />

28.6<br />

36.3<br />

1.21<br />

1.44<br />

2.6<br />

3.2<br />

21.3<br />

21.3<br />

15 Medium<br />

Heavy<br />

1120<br />

1410<br />

7.71<br />

9.70<br />

1170<br />

1470<br />

8.05<br />

10.1<br />

1270<br />

1590<br />

8.73<br />

11.0<br />

1420<br />

1780<br />

9.75<br />

12.3<br />

1600<br />

2010<br />

11.0<br />

13.8<br />

1780<br />

2240<br />

12.2<br />

15.4<br />

1960<br />

2460<br />

13.5<br />

17.0<br />

2140<br />

2690<br />

14.7<br />

18.5<br />

3210<br />

4040<br />

22.1<br />

27.8<br />

1.56<br />

1.87<br />

2.6<br />

3.2<br />

26.9<br />

26.9<br />

20 Medium<br />

Heavy<br />

1100<br />

1400<br />

7.56<br />

9.68<br />

1150<br />

1470<br />

7.90<br />

10.1<br />

1240<br />

1590<br />

8.56<br />

11.0<br />

1390<br />

1780<br />

9.56<br />

12.2<br />

1570<br />

2000<br />

10.8<br />

13.8<br />

1740<br />

2230<br />

12.0<br />

15.4<br />

1920<br />

2460<br />

13.2<br />

16.9<br />

2100<br />

2690<br />

14.5<br />

18.5<br />

3150<br />

4030<br />

21.7<br />

27.8<br />

2.41<br />

2.94<br />

3.2<br />

4.0<br />

33.7<br />

33.7<br />

25 Medium<br />

Heavy<br />

856<br />

1090<br />

5.90<br />

7.51<br />

894<br />

1140<br />

6.16<br />

7.84<br />

969<br />

1230<br />

6.68<br />

8.50<br />

1080<br />

1380<br />

7.46<br />

9.50<br />

1220<br />

1550<br />

8.41<br />

10.7<br />

1360<br />

1730<br />

9.37<br />

11.9<br />

1500<br />

1910<br />

10.3<br />

13.1<br />

1640<br />

2080<br />

11.3<br />

14.4<br />

2450<br />

3120<br />

16.9<br />

21.5<br />

3.10<br />

3.80<br />

3.2<br />

4.0<br />

42.4<br />

42.4<br />

32 Medium<br />

Heavy<br />

745<br />

946<br />

5.13<br />

6.52<br />

778<br />

988<br />

5.36<br />

6.80<br />

843<br />

1070<br />

5.81<br />

7.38<br />

942<br />

1200<br />

6.49<br />

8.24<br />

1060<br />

1350<br />

7.32<br />

9.30<br />

1180<br />

1500<br />

8.15<br />

10.4<br />

1300<br />

1660<br />

8.98<br />

11.4<br />

1420<br />

1810<br />

9.81<br />

12.5<br />

2140<br />

2710<br />

14.7<br />

18.7<br />

3.57<br />

4.38<br />

3.2<br />

4.0<br />

48.3<br />

48.3<br />

40 Medium<br />

Heavy<br />

Notes:<br />

1. The above maximum recommended test and working pressures are applicable only to the pipe, if and only if<br />

• The applied loads are only from internal pressure in straight pipe. The pipeline should be supported so that bending and external loads are avoided. The pipeline must also be set up with suitable<br />

freedom of angular movement at joints and bends and with provision to accommodate thermal expansion.<br />

• The maximum working pressure is based on a design strength of 130 MPa at 50ºC, and 90% of the nominal wall thickness to allow for the minimum thickness tolerance of the relevant standard.<br />

• AS 4041 limits the maximum pressure of this type of pipe (Class 2) to 10 MPa when carrying Very Harmful Fluids (fluid type 2) and for Harmful gases (fluid type 3). This should be considered when<br />

designing pipelines. See the OneStreel publication ‘Fluid type and classes for pressure piping systems’ for information on fluid types.<br />

• Use of this pipe is prohibited where the pipe contents are Lethal (AS 4041 fluid type 1). See the OneSteel publication ‘Fluid type and classes for pressure piping systems’ for information on fluid types.<br />

2. The piping system working pressures can be limited by the type of couplings or the welding class used in the design of the pipeline.<br />

3. AS 3920.1 gives information on the hazard level of pressure piping and other pressure equipment and the QA required to certify design, manufacture and installation.<br />

4. Pressures have been calculated in accordance with AS 4041-1998 and the draft revision ME/1/8/00-28. p=2feMtf /(D-tf) where<br />

p = Safe working pressure. M = 0.7 Class design factor from AS 4041 table 3.12.3 for class 2.<br />

f = Design strengths from table D2 of AS 4041 for AS 1074 product. tf = 0.9 x wall thickness, in mm.<br />

e = 0.85 Weld joint factor from table 3.12.2 of AS 4041 for AS 1074 ERW product. D = Outside diameter, in mm.<br />

5. No allowance has been made for corrosion, threading, grooving or machining.<br />

68<br />

Dimensions and Properties Handbook