lauren@kelman.ca

1YLWYxL

1YLWYxL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TERTIARY TREATMENT TECHNOLOGIES & PRACTICES<br />

Current Best Practices<br />

for Chemi<strong>ca</strong>l Phosphorus Removal<br />

BY JEREMY KRAEMER, PH.D., P.ENG., CH2M<br />

Wastewater treatment plants (WWTPs)<br />

in Ontario have been required to<br />

reduce phosphorus (P) to at least<br />

1 mg/L since the 1970s, with effluent<br />

limits down to 0.3 to 0.5 mg/L<br />

becoming common through the 1990s.<br />

Currently, effluent limits of 0.1 mg/L or<br />

less are frequently required when plants<br />

are expanded, particularly inland<br />

where receivers are often Policy 2 with<br />

respect to phosphorus (P). Except for<br />

a handful of biologi<strong>ca</strong>l phosphorus<br />

removal WWTPs, P removal in Ontario<br />

is achieved by chemi<strong>ca</strong>l treatment<br />

typi<strong>ca</strong>lly using ‘alum’ (aluminum<br />

sulphate) or ‘ferric’ (ferric chloride or<br />

ferric sulphate). A few plants still use<br />

‘ferrous’ (ferrous sulphate, sometimes<br />

referred to as pickle liquor), however<br />

it requires oxidation before it becomes<br />

effective and its use is in decline and<br />

will not be covered in this article.<br />

This article will discuss current best<br />

practices the reader <strong>ca</strong>n employ to<br />

remove phosphorus to low levels while<br />

minimizing alum or ferric use and<br />

associated cost.<br />

Types of phosphorus<br />

To understand P removal we must<br />

understand the types of P in wastewater.<br />

Although P occurs naturally in many<br />

different forms (organic P, ortho-P,<br />

polyphosphates, etc.), generally we are<br />

interested in two functional <strong>ca</strong>tegories:<br />

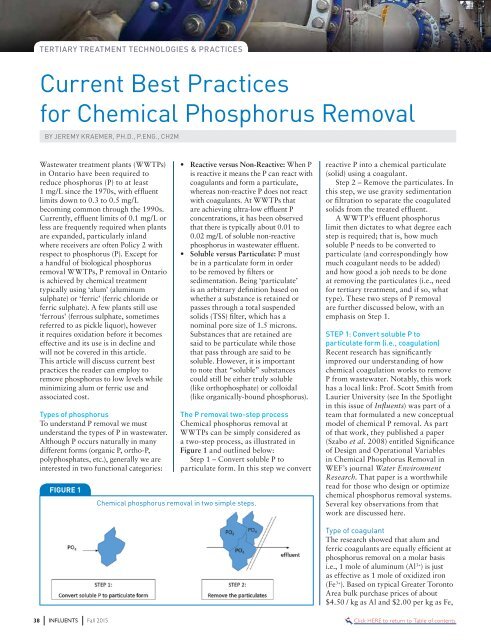

FIGURE 1<br />

• Reactive versus Non-Reactive: When P<br />

is reactive it means the P <strong>ca</strong>n react with<br />

coagulants and form a particulate,<br />

whereas non-reactive P does not react<br />

with coagulants. At WWTPs that<br />

are achieving ultra-low effluent P<br />

concentrations, it has been observed<br />

that there is typi<strong>ca</strong>lly about 0.01 to<br />

0.02 mg/L of soluble non-reactive<br />

phosphorus in wastewater effluent.<br />

• Soluble versus Particulate: P must<br />

be in a particulate form in order<br />

to be removed by filters or<br />

sedimentation. Being ‘particulate’<br />

is an arbitrary definition based on<br />

whether a substance is retained or<br />

passes through a total suspended<br />

solids (TSS) filter, which has a<br />

nominal pore size of 1.5 microns.<br />

Substances that are retained are<br />

said to be particulate while those<br />

that pass through are said to be<br />

soluble. However, it is important<br />

to note that “soluble” substances<br />

could still be either truly soluble<br />

(like orthophosphate) or colloidal<br />

(like organi<strong>ca</strong>lly-bound phosphorus).<br />

The P removal two-step process<br />

Chemi<strong>ca</strong>l phosphorus removal at<br />

WWTPs <strong>ca</strong>n be simply considered as<br />

a two-step process, as illustrated in<br />

Figure 1 and outlined below:<br />

Step 1 – Convert soluble P to<br />

particulate form. In this step we convert<br />

Chemi<strong>ca</strong>l phosphorus removal in two simple steps.<br />

reactive P into a chemi<strong>ca</strong>l particulate<br />

(solid) using a coagulant.<br />

Step 2 – Remove the particulates. In<br />

this step, we use gravity sedimentation<br />

or filtration to separate the coagulated<br />

solids from the treated effluent.<br />

A WWTP’s effluent phosphorus<br />

limit then dictates to what degree each<br />

step is required; that is, how much<br />

soluble P needs to be converted to<br />

particulate (and correspondingly how<br />

much coagulant needs to be added)<br />

and how good a job needs to be done<br />

at removing the particulates (i.e., need<br />

for tertiary treatment, and if so, what<br />

type). These two steps of P removal<br />

are further discussed below, with an<br />

emphasis on Step 1.<br />

STEP 1: Convert soluble P to<br />

particulate form (i.e., coagulation)<br />

Recent research has signifi<strong>ca</strong>ntly<br />

improved our understanding of how<br />

chemi<strong>ca</strong>l coagulation works to remove<br />

P from wastewater. Notably, this work<br />

has a lo<strong>ca</strong>l link: Prof. Scott Smith from<br />

Laurier University (see In the Spotlight<br />

in this issue of Influents) was part of a<br />

team that formulated a new conceptual<br />

model of chemi<strong>ca</strong>l P removal. As part<br />

of that work, they published a paper<br />

(Szabo et al. 2008) entitled Signifi<strong>ca</strong>nce<br />

of Design and Operational Variables<br />

in Chemi<strong>ca</strong>l Phosphorus Removal in<br />

WEF’s journal Water Environment<br />

Research. That paper is a worthwhile<br />

read for those who design or optimize<br />

chemi<strong>ca</strong>l phosphorus removal systems.<br />

Several key observations from that<br />

work are discussed here.<br />

Type of coagulant<br />

The research showed that alum and<br />

ferric coagulants are equally efficient at<br />

phosphorus removal on a molar basis<br />

i.e., 1 mole of aluminum (Al 3+ ) is just<br />

as effective as 1 mole of oxidized iron<br />

(Fe 3+ ). Based on typi<strong>ca</strong>l Greater Toronto<br />

Area bulk purchase prices of about<br />

$4.50 / kg as Al and $2.00 per kg as Fe,<br />

38 INFLUENTS Fall 2015<br />

Click HERE to return to Table of contents