lauren@kelman.ca

1YLWYxL

1YLWYxL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TERTIARY TREATMENT TECHNOLOGIES & PRACTICES<br />

concentration <strong>ca</strong>n be constantly below<br />

0.05 mg/L, if sufficient ferric is added<br />

into the process.<br />

For the Barrie Wastewater Treatment<br />

Facility (WWTF), Barrie, Ontario, the<br />

liquid treatment processes include a<br />

high purity oxygen process, secondary<br />

clarifiers, rotary biologi<strong>ca</strong>l contactors<br />

(RBCs) and traveling bridge single-media<br />

sand filters. Histori<strong>ca</strong>l performance<br />

shows that the Barrie WWTF <strong>ca</strong>n reliably<br />

achieve effluent TP of 0.15 mg/L with<br />

the existing sand filters operating at their<br />

rated <strong>ca</strong>pacity. Under the Lake Simcoe<br />

Phosphorus Reduction Strategy, the<br />

Barrie WWTF needs to produce effluent<br />

with a TP limit of 0.1 mg/L. In order to<br />

reliably meet 0.1 mg/L effluent TP, the<br />

City of Barrie is currently conducting an<br />

engineering design assignment to retrofit<br />

one existing secondary clarifier into an<br />

MBR process. This MBR train will treat<br />

a portion of the total flow to achieve<br />

ultra-low TP concentration of 0.05 mg/L<br />

and below, and the MBR effluent will<br />

be blended with the remaining sand<br />

filtration effluent to meet the effluent TP<br />

concentration of 0.1 mg/L.<br />

Tertiary low-pressure<br />

membrane filtration<br />

Low-pressure membrane filtration<br />

<strong>ca</strong>n also be used as a tertiary step to<br />

polish the secondary clarifier effluent.<br />

Microfiltration (MF) membranes have<br />

approximately 0.2 microgram (μm)<br />

pores, and ultrafiltration (UF) membranes<br />

have approximately 0.02-μm pores.<br />

Both MF and UF <strong>ca</strong>n be used to provide<br />

tertiary filtration treatment to reliably<br />

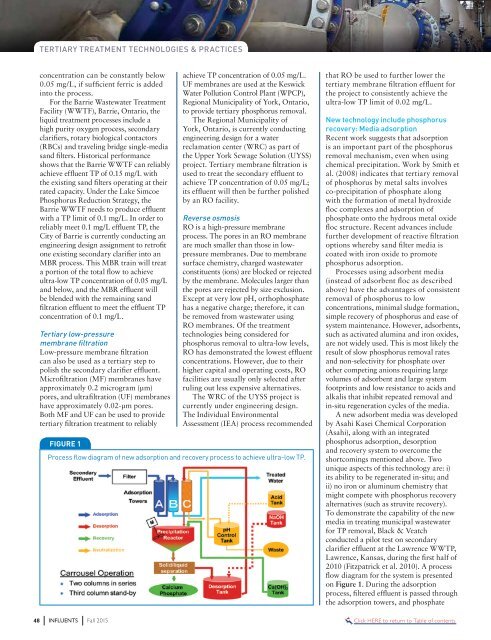

FIGURE 1<br />

achieve TP concentration of 0.05 mg/L.<br />

UF membranes are used at the Keswick<br />

Water Pollution Control Plant (WPCP),<br />

Regional Municipality of York, Ontario,<br />

to provide tertiary phosphorus removal.<br />

The Regional Municipality of<br />

York, Ontario, is currently conducting<br />

engineering design for a water<br />

reclamation center (WRC) as part of<br />

the Upper York Sewage Solution (UYSS)<br />

project. Tertiary membrane filtration is<br />

used to treat the secondary effluent to<br />

achieve TP concentration of 0.05 mg/L;<br />

its effluent will then be further polished<br />

by an RO facility.<br />

Reverse osmosis<br />

RO is a high-pressure membrane<br />

process. The pores in an RO membrane<br />

are much smaller than those in lowpressure<br />

membranes. Due to membrane<br />

surface chemistry, charged wastewater<br />

constituents (ions) are blocked or rejected<br />

by the membrane. Molecules larger than<br />

the pores are rejected by size exclusion.<br />

Except at very low pH, orthophosphate<br />

has a negative charge; therefore, it <strong>ca</strong>n<br />

be removed from wastewater using<br />

RO membranes. Of the treatment<br />

technologies being considered for<br />

phosphorus removal to ultra-low levels,<br />

RO has demonstrated the lowest effluent<br />

concentrations. However, due to their<br />

higher <strong>ca</strong>pital and operating costs, RO<br />

facilities are usually only selected after<br />

ruling out less expensive alternatives.<br />

The WRC of the UYSS project is<br />

currently under engineering design.<br />

The Individual Environmental<br />

Assessment (IEA) process recommended<br />

Process flow diagram of new adsorption and recovery process to achieve ultra-low TP.<br />

48 INFLUENTS Fall 2015<br />

that RO be used to further lower the<br />

tertiary membrane filtration effluent for<br />

the project to consistently achieve the<br />

ultra-low TP limit of 0.02 mg/L.<br />

New technology include phosphorus<br />

recovery: Media adsorption<br />

Recent work suggests that adsorption<br />

is an important part of the phosphorus<br />

removal mechanism, even when using<br />

chemi<strong>ca</strong>l precipitation. Work by Smith et<br />

al. (2008) indi<strong>ca</strong>tes that tertiary removal<br />

of phosphorus by metal salts involves<br />

co-precipitation of phosphate along<br />

with the formation of metal hydroxide<br />

floc complexes and adsorption of<br />

phosphate onto the hydrous metal oxide<br />

floc structure. Recent advances include<br />

further development of reactive filtration<br />

options whereby sand filter media is<br />

coated with iron oxide to promote<br />

phosphorus adsorption.<br />

Processes using adsorbent media<br />

(instead of adsorbent floc as described<br />

above) have the advantages of consistent<br />

removal of phosphorus to low<br />

concentrations, minimal sludge formation,<br />

simple recovery of phosphorus and ease of<br />

system maintenance. However, adsorbents,<br />

such as activated alumina and iron oxides,<br />

are not widely used. This is most likely the<br />

result of slow phosphorus removal rates<br />

and non-selectivity for phosphate over<br />

other competing anions requiring large<br />

volumes of adsorbent and large system<br />

footprints and low resistance to acids and<br />

alkalis that inhibit repeated removal and<br />

in-situ regeneration cycles of the media.<br />

A new adsorbent media was developed<br />

by Asahi Kasei Chemi<strong>ca</strong>l Corporation<br />

(Asahi), along with an integrated<br />

phosphorus adsorption, desorption<br />

and recovery system to overcome the<br />

shortcomings mentioned above. Two<br />

unique aspects of this technology are: i)<br />

its ability to be regenerated in-situ; and<br />

ii) no iron or aluminum chemistry that<br />

might compete with phosphorus recovery<br />

alternatives (such as struvite recovery).<br />

To demonstrate the <strong>ca</strong>pability of the new<br />

media in treating municipal wastewater<br />

for TP removal, Black & Veatch<br />

conducted a pilot test on secondary<br />

clarifier effluent at the Lawrence WWTP,<br />

Lawrence, Kansas, during the first half of<br />

2010 (Fitzpatrick et al. 2010). A process<br />

flow diagram for the system is presented<br />

on Figure 1. During the adsorption<br />

process, filtered effluent is passed through<br />

the adsorption towers, and phosphate<br />

Click HERE to return to Table of contents