Conveying with ease Assembly, operating and insertion - Denipro

Conveying with ease Assembly, operating and insertion - Denipro

Conveying with ease Assembly, operating and insertion - Denipro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5 <strong>Assembly</strong> instructions<br />

Pl<strong>ease</strong> note:<br />

Geometrically, the conveying line must be correctly<br />

positioned for the denirug ® heavy-duty support to<br />

function reliably.<br />

denirug ® heavy-duty supports can be assembled in different<br />

ways (see sections 5.1 <strong>and</strong> 5.2). The following principles must<br />

be complied <strong>with</strong>:<br />

– Each denirug ® heavy-duty support is affi xed separately.<br />

– In accordance <strong>with</strong> the subsequent load, the base must<br />

be able to bear loads, horizontal <strong>and</strong> fl at. In the case<br />

of gravity conveying, minimum inclination is required<br />

<strong>and</strong> must be established by carrying out tests.<br />

– The distribution of the denirug ® heavy-duty supports is<br />

carefully planned separately according to the subsequent<br />

load distribution. The loads stated in the data sheets must<br />

not be exceeded. Support is often advisable in several<br />

tracks, where the heavy-duty supports are fi tted behind<br />

one another.<br />

– The supports must be fi tted precisely in the conveying<br />

direction. If there are several tracks, ensure they are<br />

parallel.<br />

– The supports are fi tted at the same height.<br />

Warning<br />

Before carrying out any assembly, maintenance<br />

<strong>and</strong> repairs, the conveyor drive’s master switch<br />

must be switched off <strong>and</strong> prevented from being<br />

switched on again.<br />

Where gravity conveyors are concerned,<br />

the area must be cordoned off appropriately<br />

<strong>and</strong> monitored.<br />

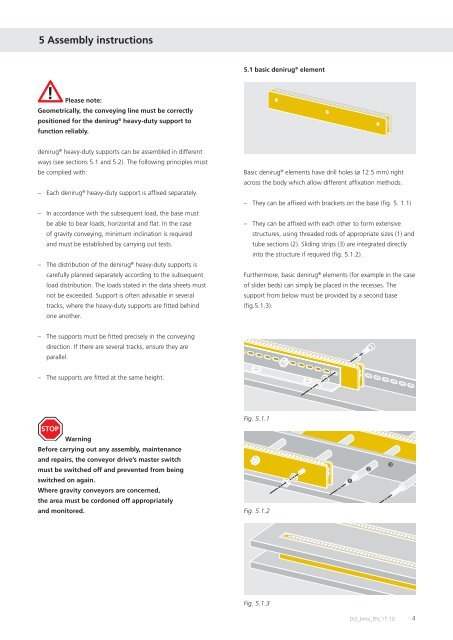

5.1 basic denirug ® element<br />

Basic denirug ® elements have drill holes (ø 12.5 mm) right<br />

across the body which allow different affi xation methods.<br />

– They can be affi xed <strong>with</strong> brackets on the base (fi g. 5. 1.1)<br />

– They can be affi xed <strong>with</strong> each other to form extensive<br />

structures, using threaded rods of appropriate sizes (1) <strong>and</strong><br />

tube sections (2). Sliding strips (3) are integrated directly<br />

into the structure if required (fi g. 5.1.2).<br />

Furthermore, basic denirug ® elements (for example in the case<br />

of slider beds) can simply be placed in the recesses. The<br />

support from below must be provided by a second base<br />

(fi g.5.1.3).<br />

Fig. 5.1.1<br />

Fig. 5.1.2<br />

Fig. 5.1.3<br />

➊<br />

➋<br />

➌<br />

DG_bma_EN_11.10<br />

4