normal - Jenoptik AG

normal - Jenoptik AG

normal - Jenoptik AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24<br />

Cornelia Ehrler<br />

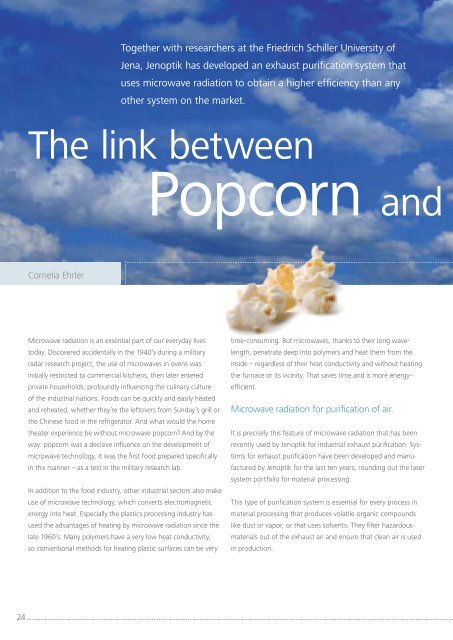

Together with researchers at the Friedrich Schiller University of<br />

Jena, <strong>Jenoptik</strong> has developed an exhaust purification system that<br />

uses microwave radiation to obtain a higher efficiency than any<br />

other system on the market.<br />

The link between<br />

Popcorn and<br />

Microwave radiation is an essential part of our everyday lives<br />

today. Discovered accidentally in the 1940’s during a military<br />

radar research project, the use of microwaves in ovens was<br />

initially restricted to commercial kitchens, then later entered<br />

private households, profoundly influencing the culinary culture<br />

of the industrial nations. Foods can be quickly and easily heated<br />

and reheated, whether they’re the leftovers from Sunday’s grill or<br />

the Chinese food in the refrigerator. And what would the home<br />

theater experience be without microwave popcorn? And by the<br />

way: popcorn was a decisive influence on the development of<br />

microwave technology. It was the first food prepared specifically<br />

in this manner – as a test in the military research lab.<br />

In addition to the food industry, other industrial sectors also make<br />

use of microwave technology, which converts electromagnetic<br />

energy into heat. Especially the plastics processing industry has<br />

used the advantages of heating by microwave radiation since the<br />

late 1960’s. Many polymers have a very low heat conductivity,<br />

so conventional methods for heating plastic surfaces can be very<br />

time-consuming. time-consuming But microwaves microwaves, thanks tto<br />

their long wavelength,<br />

penetrate deep into polymers and heat them from the<br />

inside – regardless of their heat conductivity and without heating<br />

the furnace or its vicinity. That saves time and is more energyefficient.<br />

Microwave radiation for purification of air.<br />

It is precisely this feature of microwave radiation that has been<br />

recently used by <strong>Jenoptik</strong> for industrial exhaust purification. Systems<br />

for exhaust purification have been developed and manufactured<br />

by <strong>Jenoptik</strong> for the last ten years, rounding out the laser<br />

system portfolio for material processing.<br />

This type of purification system is essential for every process in<br />

material processing that produces volatile organic compounds<br />

like dust or vapor, or that uses solvents. They filter hazardous<br />

materials out of the exhaust air and ensure that clean air is used<br />

in production.