normal - Jenoptik AG

normal - Jenoptik AG

normal - Jenoptik AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

Jana Dichelle<br />

Unplanned<br />

stroke of genius<br />

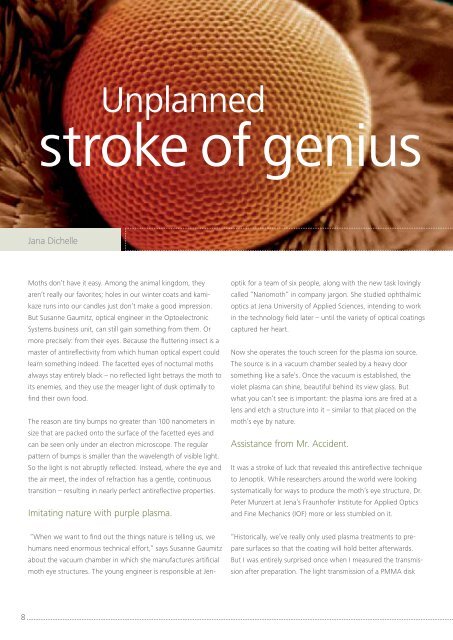

Moths don’t have it easy. Among the animal kingdom, they<br />

aren’t really our favorites; holes in our winter coats and kamikaze<br />

runs into our candles just don’t make a good impression.<br />

But Susanne Gaumitz, optical engineer in the Optoelectronic<br />

Systems business unit, can still gain something from them. Or<br />

more precisely: from their eyes. Because the fluttering insect is a<br />

master of antireflectivity from which human optical expert could<br />

learn something indeed. The facetted eyes of nocturnal moths<br />

always stay entirely black – no reflected light betrays the moth to<br />

its enemies, and they use the meager light of dusk optimally to<br />

find their own food.<br />

The reason are tiny bumps no greater than 100 nanometers in<br />

size that are packed onto the surface of the facetted eyes and<br />

can be seen only under an electron microscope. The regular<br />

pattern of bumps is smaller than the wavelength of visible light.<br />

So the light is not abruptly reflected. Instead, where the eye and<br />

the air meet, the index of refraction has a gentle, continuous<br />

transition – resulting in nearly perfect antireflective properties.<br />

Imitating nature with purple plasma.<br />

“When we want to find out the things nature is telling us, we<br />

humans need enormous technical effort,” says Susanne Gaumitz<br />

about the vacuum chamber in which she manufactures artificial<br />

moth eye structures. The young engineer is responsible at Jen-<br />

optik for a team of six people, along with the new task lovingly<br />

called “Nanomoth” in company jargon. She studied ophthalmic<br />

optics at Jena University of Applied Sciences, intending to work<br />

in the technology field later – until the variety of optical coatings<br />

captured her heart.<br />

Now she operates the touch screen for the plasma ion source.<br />

The source is in a vacuum chamber sealed by a heavy door<br />

something like a safe’s. Once the vacuum is established, the<br />

violet plasma can shine, beautiful behind its view glass. But<br />

what you can’t see is important: the plasma ions are fired at a<br />

lens and etch a structure into it – similar to that placed on the<br />

moth’s eye by nature.<br />

Assistance from Mr. Accident.<br />

It was a stroke of luck that revealed this antireflective technique<br />

to <strong>Jenoptik</strong>. While researchers around the world were looking<br />

systematically for ways to produce the moth’s eye structure, Dr.<br />

Peter Munzert at Jena’s Fraunhofer Institute for Applied Optics<br />

and Fine Mechanics (IOF) more or less stumbled on it.<br />

“Historically, we’ve really only used plasma treatments to prepare<br />

surfaces so that the coating will hold better afterwards.<br />

But I was entirely surprised once when I measured the transmission<br />

after preparation. The light transmission of a PMMA disk