Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Timken</strong> ® SAF SPLIT-BLOCK HOUSED UNITS<br />

Engineering • SAF Lubrication<br />

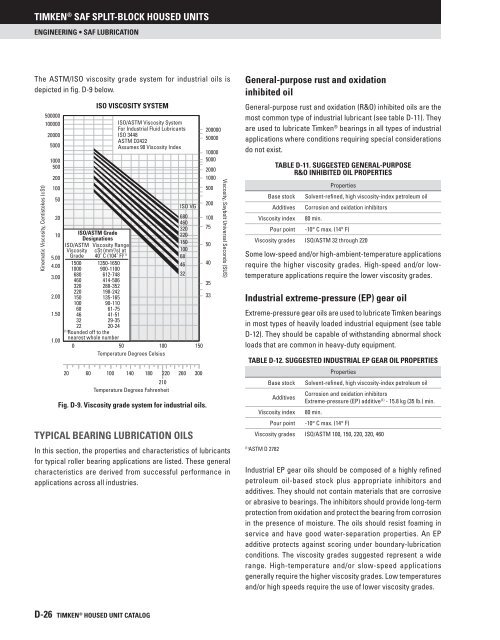

The ASTM/ISO viscosity grade system for industrial oils is<br />

depicted in fig. D-9 below.<br />

Kinematic Viscosity, Centistokes (cSt)<br />

500000<br />

100000<br />

20000<br />

5000<br />

1000<br />

500<br />

200<br />

100<br />

50<br />

20<br />

10<br />

5.00<br />

4.00<br />

3.00<br />

2.00<br />

1.50<br />

1.00<br />

ISO/ASTM Grade<br />

Designations<br />

ISO/ASTM Viscosity Range<br />

Viscosity cSt (mm 2 /s) at<br />

Grade 40˚ C (104˚ F) (1)<br />

1500 1350-1650<br />

1000 900-1100<br />

680 612-748<br />

460 414-506<br />

320 288-352<br />

220 198-242<br />

150 135-165<br />

100 90-110<br />

68 61-75<br />

46 41-51<br />

32 29-35<br />

22 20-24<br />

(1)<br />

Rounded off to the<br />

nearest whole number<br />

ISO viscosity system<br />

ISO/ASTM Viscosity System<br />

For Industrial Fluid Lubricants<br />

ISO 3448<br />

ASTM D2422<br />

Assumes 90 Viscosity Index<br />

ISO VG<br />

680<br />

460<br />

320<br />

220<br />

150<br />

100<br />

68<br />

46<br />

32<br />

0 50 100 150<br />

Temperature Degrees Celsius<br />

20 60 100 140 180 220 260 300<br />

210<br />

Temperature Degrees Fahrenheit<br />

Fig. D-9. Viscosity grade system for industrial oils.<br />

typical bearing lubrication oils<br />

200000<br />

50000<br />

10000<br />

5000<br />

2000<br />

1000<br />

500<br />

In this section, the properties and characteristics of lubricants<br />

for typical roller bearing applications are listed. These general<br />

characteristics are derived from successful performance in<br />

applications across all industries.<br />

200<br />

100<br />

75<br />

50<br />

40<br />

35<br />

33<br />

Viscosity, Saybolt Universal Seconds (SUS)<br />

General-purpose rust and oxidation<br />

inhibited oil<br />

General-purpose rust and oxidation (R&O) inhibited oils are the<br />

most common type of industrial lubricant (see table D-11). They<br />

are used to lubricate <strong>Timken</strong> ® bearings in all types of industrial<br />

applications where conditions requiring special considerations<br />

do not exist.<br />

TABLE D-11. Suggested general-purpose<br />

R&O INHIBITED oil properties<br />

Properties<br />

Base stock Solvent-refined, high viscosity-index petroleum oil<br />

Additives Corrosion and oxidation inhibitors<br />

Viscosity index 80 min.<br />

Pour point -10° C max. (14° F)<br />

Viscosity grades ISO/ASTM 32 through 220<br />

Some low-speed and/or high-ambient-temperature applications<br />

require the higher viscosity grades. High-speed and/or lowtemperature<br />

applications require the lower viscosity grades.<br />

Industrial extreme-pressure (EP) gear oil<br />

Extreme-pressure gear oils are used to lubricate <strong>Timken</strong> bearings<br />

in most types of heavily loaded industrial equipment (see table<br />

D-12). They should be capable of withstanding abnormal shock<br />

loads that are common in heavy-duty equipment.<br />

TABLE D-12. SUGGESTED INDUSTRIAL EP GEAR OIL PROPERTIES<br />

Properties<br />

Base stock Solvent-refined, high viscosity-index petroleum oil<br />

Additives<br />

Corrosion and oxidation inhibitors<br />

Extreme-pressure (EP) additive (1) - 15.8 kg (35 lb.) min.<br />

Viscosity index 80 min.<br />

Pour point -10° C max. (14° F)<br />

Viscosity grades ISO/ASTM 100, 150, 220, 320, 460<br />

(1)<br />

ASTM D 2782<br />

Industrial EP gear oils should be composed of a highly refined<br />

petroleum oil-based stock plus appropriate inhibitors and<br />

additives. They should not contain materials that are corrosive<br />

or abrasive to bearings. The inhibitors should provide long-term<br />

protection from oxidation and protect the bearing from corrosion<br />

in the presence of moisture. The oils should resist foaming in<br />

service and have good water-separation properties. An EP<br />

additive protects against scoring under boundary-lubrication<br />

conditions. The viscosity grades suggested represent a wide<br />

range. High-temperature and/or slow-speed applications<br />

generally require the higher viscosity grades. Low temperatures<br />

and/or high speeds require the use of lower viscosity grades.<br />

D-26 TIMKEN ® HOUSED UNIT CATALOG