MEATing POINT Magazine: #08/ 2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENERGY EFFICIENCY<br />

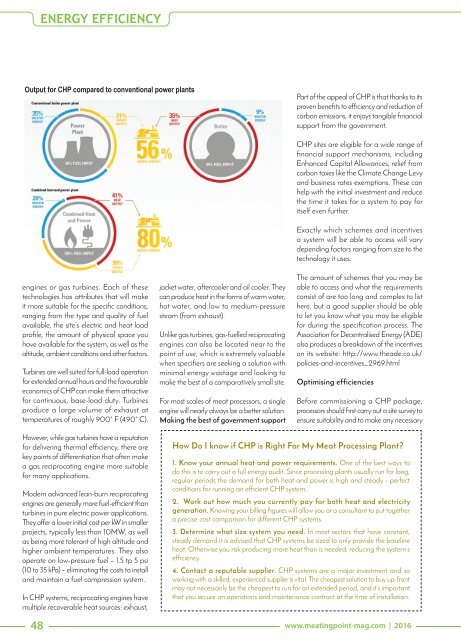

Output for CHP compared to conventional power plants<br />

Part of the appeal of CHP is that thanks to its<br />

proven benefits to efficiency and reduction of<br />

carbon emissions, it enjoys tangible financial<br />

support from the government.<br />

engines or gas turbines. Each of these<br />

technologies has attributes that will make<br />

it more suitable for the specific conditions,<br />

ranging from the type and quality of fuel<br />

available, the site’s electric and heat load<br />

profile, the amount of physical space you<br />

have available for the system, as well as the<br />

altitude, ambient conditions and other factors.<br />

Turbines are well suited for full-load operation<br />

for extended annual hours and the favourable<br />

economics of CHP can make them attractive<br />

for continuous, base-load duty. Turbines<br />

produce a large volume of exhaust at<br />

temperatures of roughly 900° F (490° C).<br />

jacket water, aftercooler and oil cooler. They<br />

can produce heat in the forms of warm water,<br />

hot water, and low to medium-pressure<br />

steam (from exhaust).<br />

Unlike gas turbines, gas-fuelled reciprocating<br />

engines can also be located near to the<br />

point of use, which is extremely valuable<br />

when specifiers are seeking a solution with<br />

minimal energy wastage and looking to<br />

make the best of a comparatively small site.<br />

For most scales of meat processors, a single<br />

engine will nearly always be a better solution.<br />

Making the best of government support<br />

CHP sites are eligible for a wide range of<br />

financial support mechanisms, including<br />

Enhanced Capital Allowances, relief from<br />

carbon taxes like the Climate Change Levy<br />

and business rates exemptions. These can<br />

help with the initial investment and reduce<br />

the time it takes for a system to pay for<br />

itself even further.<br />

Exactly which schemes and incentives<br />

a system will be able to access will vary<br />

depending factors ranging from size to the<br />

technology it uses.<br />

The amount of schemes that you may be<br />

able to access and what the requirements<br />

consist of are too long and complex to list<br />

here, but a good supplier should be able<br />

to let you know what you may be eligible<br />

for during the specification process. The<br />

Association for Decentralised Energy (ADE)<br />

also produces a breakdown of the incentives<br />

on its website: http://www.theade.co.uk/<br />

policies-and-incentives_2969.html<br />

Optimising efficiencies<br />

Before commissioning a CHP package,<br />

processors should first carry out a site survey to<br />

ensure suitability and to make any necessary<br />

However, while gas turbines have a reputation<br />

for delivering thermal efficiency, there are<br />

key points of differentiation that often make<br />

a gas reciprocating engine more suitable<br />

for many applications.<br />

Modern advanced lean-burn reciprocating<br />

engines are generally more fuel-efficient than<br />

turbines in pure electric power applications.<br />

They offer a lower initial cost per kW in smaller<br />

projects, typically less than 10MW, as well<br />

as being more tolerant of high altitude and<br />

higher ambient temperatures. They also<br />

operate on low-pressure fuel – 1.5 tp 5 psi<br />

(10 to 35 kPa) – eliminating the costs to install<br />

and maintain a fuel compression system.<br />

In CHP systems, reciprocating engines have<br />

multiple recoverable heat sources: exhaust,<br />

How Do I know if CHP is Right For My Meat Processing Plant?<br />

1. Know your annual heat and power requirements. One of the best ways to<br />

do this is to carry out a full energy audit. Since processing plants usually run for long,<br />

regular periods the demand for both heat and power is high and steady - perfect<br />

conditions for running an efficient CHP system.<br />

2. Work out how much you currently pay for both heat and electricity<br />

generation. Knowing your billing figures will allow you or a consultant to put together<br />

a precise cost comparison for different CHP systems.<br />

3. Determine what size system you need. In most sectors that have constant,<br />

steady demand it is advised that CHP systems be sized to only provide the baseline<br />

heat. Otherwise you risk producing more heat than is needed, reducing the system’s<br />

efficiency.<br />

4. Contact a reputable supplier. CHP systems are a major investment and so<br />

working with a skilled, experienced supplier is vital. The cheapest solution to buy up-front<br />

may not necessarily be the cheapest to run for an extended period, and it’s important<br />

that you secure an operations and maintenance contract at the time of installation.<br />

48 www.meatingpoint-mag.com | <strong>2016</strong>