Iraqi Kurdistan All in the Timing

GEO_ExPro_v12i6

GEO_ExPro_v12i6

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rangely field, yield<strong>in</strong>g just 10<br />

barrels per day.<br />

Almost 30 years after those<br />

first disappo<strong>in</strong>t<strong>in</strong>g wells were<br />

drilled, Raven A-1 was spudded<br />

by <strong>the</strong> California Company<br />

(now Chevron) <strong>in</strong> 1931. It took<br />

more than a year to drill down<br />

to an oil saturated sandstone at<br />

a depth of 1,931m. In 1933, <strong>the</strong><br />

well tested at 230 bopd from <strong>the</strong><br />

Weber sandstone and rema<strong>in</strong>ed<br />

shut <strong>in</strong> for 10 years after<br />

produc<strong>in</strong>g 8,000 bo. The well<br />

had discovered a huge field with<br />

more than 1.9 billion barrels<br />

oil-<strong>in</strong>-place, but it would take<br />

World War II to <strong>in</strong>crease <strong>the</strong><br />

demand for oil before <strong>the</strong> remote<br />

field would be developed. S<strong>in</strong>ce<br />

<strong>the</strong>n, <strong>the</strong> field has undergone<br />

a multitude of projects that<br />

have slowed production decl<strong>in</strong>e<br />

and greatly <strong>in</strong>creased <strong>the</strong> overall oil<br />

recovery. Chevron learned early on that to<br />

effectively produce this complex reservoir,<br />

<strong>the</strong>y had to rely on <strong>the</strong> operations<br />

personnel to closely monitor each well <strong>in</strong><br />

order to make timely adjustments to <strong>the</strong>ir<br />

production programme.<br />

Production History<br />

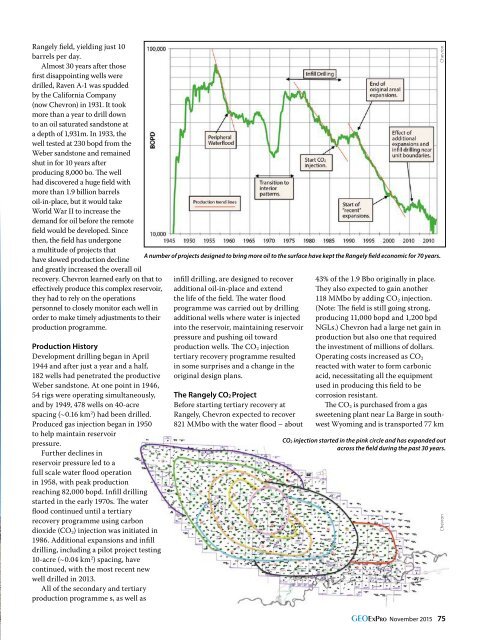

Development drill<strong>in</strong>g began <strong>in</strong> April<br />

1944 and after just a year and a half,<br />

182 wells had penetrated <strong>the</strong> productive<br />

Weber sandstone. At one po<strong>in</strong>t <strong>in</strong> 1946,<br />

54 rigs were operat<strong>in</strong>g simultaneously,<br />

and by 1949, 478 wells on 40-acre<br />

spac<strong>in</strong>g (~0.16 km 2 ) had been drilled.<br />

Produced gas <strong>in</strong>jection began <strong>in</strong> 1950<br />

to help ma<strong>in</strong>ta<strong>in</strong> reservoir<br />

pressure.<br />

Fur<strong>the</strong>r decl<strong>in</strong>es <strong>in</strong><br />

reservoir pressure led to a<br />

full scale water flood operation<br />

<strong>in</strong> 1958, with peak production<br />

reach<strong>in</strong>g 82,000 bopd. Infill drill<strong>in</strong>g<br />

started <strong>in</strong> <strong>the</strong> early 1970s. The water<br />

flood cont<strong>in</strong>ued until a tertiary<br />

recovery programme us<strong>in</strong>g carbon<br />

dioxide (CO 2 ) <strong>in</strong>jection was <strong>in</strong>itiated <strong>in</strong><br />

1986. Additional expansions and <strong>in</strong>fill<br />

drill<strong>in</strong>g, <strong>in</strong>clud<strong>in</strong>g a pilot project test<strong>in</strong>g<br />

10-acre (~0.04 km 2 ) spac<strong>in</strong>g, have<br />

cont<strong>in</strong>ued, with <strong>the</strong> most recent new<br />

well drilled <strong>in</strong> 2013.<br />

<strong>All</strong> of <strong>the</strong> secondary and tertiary<br />

production programme s, as well as<br />

A number of projects designed to br<strong>in</strong>g more oil to <strong>the</strong> surface have kept <strong>the</strong> Rangely field economic for 70 years.<br />

<strong>in</strong>fill drill<strong>in</strong>g, are designed to recover<br />

additional oil-<strong>in</strong>-place and extend<br />

<strong>the</strong> life of <strong>the</strong> field. The water flood<br />

programme was carried out by drill<strong>in</strong>g<br />

additional wells where water is <strong>in</strong>jected<br />

<strong>in</strong>to <strong>the</strong> reservoir, ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g reservoir<br />

pressure and push<strong>in</strong>g oil toward<br />

production wells. The CO 2 <strong>in</strong>jection<br />

tertiary recovery programme resulted<br />

<strong>in</strong> some surprises and a change <strong>in</strong> <strong>the</strong><br />

orig<strong>in</strong>al design plans.<br />

The Rangely CO2 Project<br />

Before start<strong>in</strong>g tertiary recovery at<br />

Rangely, Chevron expected to recover<br />

821 MMbo with <strong>the</strong> water flood – about<br />

CO 2 <strong>in</strong>jection started <strong>in</strong> <strong>the</strong> p<strong>in</strong>k circle and has expanded out<br />

across <strong>the</strong> field dur<strong>in</strong>g <strong>the</strong> past 30 years.<br />

Chevron<br />

43% of <strong>the</strong> 1.9 Bbo orig<strong>in</strong>ally <strong>in</strong> place.<br />

They also expected to ga<strong>in</strong> ano<strong>the</strong>r<br />

118 MMbo by add<strong>in</strong>g CO 2 <strong>in</strong>jection.<br />

(Note: The field is still go<strong>in</strong>g strong,<br />

produc<strong>in</strong>g 11,000 bopd and 1,200 bpd<br />

NGLs.) Chevron had a large net ga<strong>in</strong> <strong>in</strong><br />

production but also one that required<br />

<strong>the</strong> <strong>in</strong>vestment of millions of dollars.<br />

Operat<strong>in</strong>g costs <strong>in</strong>creased as CO 2<br />

reacted with water to form carbonic<br />

acid, necessitat<strong>in</strong>g all <strong>the</strong> equipment<br />

used <strong>in</strong> produc<strong>in</strong>g this field to be<br />

corrosion resistant.<br />

The CO 2 is purchased from a gas<br />

sweeten<strong>in</strong>g plant near La Barge <strong>in</strong> southwest<br />

Wyom<strong>in</strong>g and is transported 77 km<br />

Chevron<br />

GEOExPro November 2015 75