FoodEurope Issue 4 2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

foodeurope<br />

INGREDIENTS PROCESSING & PACKAGING ANALYSIS<br />

THE QUARTERLY MAGAZINE FOR THE FOOD AND BEVERAGE INDUSTRIES IN EUROPE<br />

www.foodmagazine.eu.com<br />

<strong>Issue</strong> 4 <strong>2016</strong><br />

FEATURING<br />

HiE & Ni <strong>2016</strong><br />

and<br />

ProSweets/ISM 2017

foreword<br />

03<br />

foreword<br />

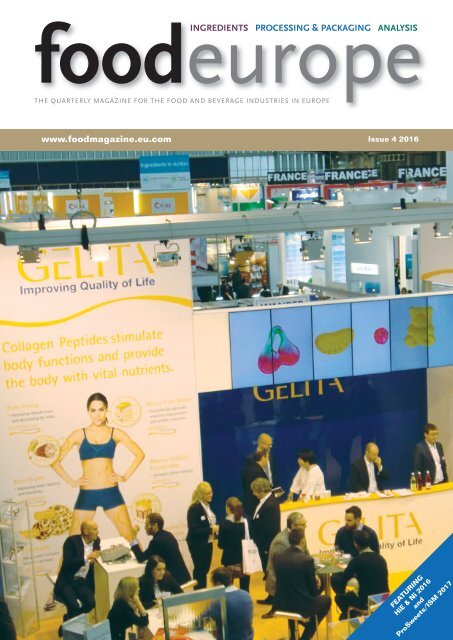

Gelita at HiE<br />

2014: Photo by<br />

Juliet Hoskins<br />

Here we are again at another end of another<br />

fast-moving year in the field of food and<br />

beverage manufacturing. New developments<br />

in processing technology, new regulations,<br />

new consumer demand, new research into<br />

health benefits and formulations…..The<br />

changing landscape of our industry demands<br />

agility and tenacity.<br />

What developments are we seeing at the<br />

moment? Visit HiE & Ni in<br />

November/December to discover the latest<br />

trends and technologies. foodeurope has produced a comprehensive<br />

preview of the show to give you a flavour, and to point you in the<br />

direction of some of the world’s greatest innovators. I look forward to<br />

seeing you there!<br />

About Food Europe<br />

Food Europe is a quarterly magazine covering the food and<br />

beverage industry in Europe. It facilitates the management<br />

processes responsible for identifying, anticipating and<br />

satisfying the needs of the European food industry.<br />

Publisher: Hoskins & Fall Publishing<br />

Calle Valiente 12, 03728 Alcalali (Alicante), Spain<br />

Tel: +34 966 48 2396<br />

Website: www.foodmagazine.eu.com<br />

Publisher: John Fall<br />

e-Mail: john@foodmagazine.eu.com<br />

Regional Manager, Spain: Ron Smee<br />

e-Mail: ron@foodmagazine.eu.com<br />

Managing Editor: Juliet Hoskins<br />

e-Mail: jhoskins@editor.eu.com<br />

Sub-editor: Hannah Smith<br />

e-Mail: hannah@foodmagazine.eu.com<br />

Designer: Zoe Sibley<br />

e-Mail: zoe@foodmagazine.eu.com<br />

Printer: Gráficas Díaz Tuduri, S.L.<br />

Tel: +34 94 4217453<br />

While the publishers believe that all information contained in this<br />

publication was correct at the time of going to press, they can accept no<br />

liability for any inaccuracies that may appear or loss suffered directly or<br />

indirectly by any reader as a result of any advertisement, editorial,<br />

photographs or other material published in Food.<br />

In our ingredients section we start with DuPont Nutrition & Health, in<br />

this edition focusing on probiotics and infant nutrition; GELITA<br />

describes its latest SMART TECHNOLOGY product range;<br />

and MANE, highly active on the world stage, focuses on its principles<br />

of respecting and giving thanks to Nature.<br />

We then have another show preview: ProSweets & ISM Cologne, taking<br />

place in January 2017. Anyone in the sweets and/or snacks industry<br />

will want to participate. It offers the complete range of supplies for the<br />

sweets and snacks industry: from innovative ingredients, to pioneering<br />

packing solutions, through to optimised production technologies.<br />

In processing and packaging, GEA describes its latest addition: the<br />

GEA PowerGrind, which, together with its big brother, can grind almost<br />

everything that’s put in it! NiceLabel expands upon the new food<br />

labelling regulation which comes into force in December, together with<br />

its solution; and Bosch Packaging Systems provides a case study on its<br />

flexible automation solutions for Bridge Natural Foods.<br />

In analysis & control, Mintel describes six key trends that are likely to<br />

impact our industry next year; Eagle Product Inspection explains its<br />

single and dual energy inspection systems including guidance on<br />

choice; and SGS Institut Fresenius provides insights into mineral oil<br />

residues in food – a highly topical issue, particularly for producers of<br />

food packaging.<br />

We have enjoyed working on this latest edition of foodeurope, and<br />

hope you enjoy reading it. We thank all of you who have supported<br />

foodeurope throughout the year and look forward to working with<br />

you in 2017.<br />

Our first edition next year will focus on Vitafoods and Interpack, and<br />

feature a review of IPPE.<br />

Seasons greetings to you all!<br />

Juliet Hoskins<br />

Editor<br />

The contents of this publication are protected by copyright.<br />

All rights reserved.<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

04<br />

contents<br />

contents<br />

08<br />

Industry News<br />

A round-up of industry news<br />

14 Show preview: HiEurope & Ni <strong>2016</strong><br />

Hi Europe & Ni <strong>2016</strong> offers priceless industry knowledge across a wide range of presentations, guided tours and<br />

showcases. Below are some of the special features that make the show so important to our industry. Meet the<br />

exhibitors who are responding to the latest trends in health and nutrition through innovation, and hear from the<br />

companies themselves about their new products.<br />

www.figlobal.com/hieurope<br />

ubm.figlobal.com/Natural/Ingredients<br />

Ingredients<br />

28<br />

32<br />

35<br />

Latest developments from DuPont Nutrition and Health<br />

Providing enough healthy food for people everywhere is a challenge. The mission of the DuPont Nutrition & Health<br />

business is to provide solutions that increase food production while lowering costs and promoting good health by<br />

lessening lifestyle diseases. DuPont Nutrition & Health is a premier specialty food ingredient and food safety<br />

leader.<br />

DuPont Nutrition & Health<br />

Facilitating the innovation game<br />

GELITA, the leading manufacturer of collagen proteins, is aware of the current changes and challenges affecting<br />

the sector. With its latest SMART TECHNOLOGY product range, ‘collagen peptides ST’, the company now offers<br />

functional ingredients that offer the best of two worlds: Bioactive Collagen Peptides® with gelling power. These<br />

novel ingredients help manufacturers to overcome growth drivers, the competition and the needs of constantly<br />

changing 201ng target groups.<br />

GELITA AG<br />

MANE: Flavours and ingredients inspired by nature<br />

This autumn, MANE has demonstrated its expertise at a number of industry leading events. This article describes<br />

those activities and provides a snapshot of the company’s main expertise in the food and beverage industry,<br />

including its tremendous respect for nature. For example, in November, the company participated in Gulfood<br />

Manufacturing, the largest and most influential trade show for the food processing and manufacturing sector in<br />

the MENASA region.<br />

MANE<br />

38<br />

Show preview: ProSweets Cologne & ISM 2017<br />

29 January – 1 February 2017, Cologne<br />

It is the only trade fair of its kind worldwide – ProSweets Cologne offers the complete range of supplies for the<br />

sweets and snacks industry: from innovative ingredients, to pioneering packing solutions, through to optimised<br />

production technologies. In effective conjunction with ISM, the world’s leading trade fair for sweets and snacks,<br />

ProSweets Cologne covers the entire value chain of the industry.<br />

www.prosweets.com<br />

www.ism-cologne.com<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

06<br />

contents<br />

Processing & Packaging<br />

42<br />

45<br />

49<br />

Meet the grinders!<br />

The GEA PowerGrind grinders grind more than ever before<br />

It’s a family thing. The physical presence of GEA’s robust grinders, the GEA PowerGrind 200 and his bigger<br />

brother the 280 send shivers down the spine! They’re perfect for grinding in burger, sausage and petfood<br />

production. In fact, they’ll grind almost everything that’s put in them – including frozen blocks and bones.<br />

GEA Food Solutions<br />

NiceLabel develops a simple solution to include mandatory nutrition facts tables in food labels<br />

December 13, <strong>2016</strong> is the deadline when all food producers must be fully compliant with the EU Food Labeling<br />

Regulation 1169/2011. NiceLabel has developed a free, simple software solution to help food suppliers achieve<br />

compliance with the regulation, with minimum effort and change to current procedures.<br />

NiceLabel<br />

Flexible secondary packaging drives fast expanding company<br />

Bridgetown Natural Foods invested in a number of impressively flexible automation solutions for its secondary<br />

packaging with not one, but three Sigpack TTM1 Cartoning Machines from Bosch Packaging Technology. The<br />

patented format change concept of the TTM1 enables easy and tool-free changeovers of pack styles and different<br />

formats – within just a few minutes.<br />

Bosch Packaging Systems AG<br />

Analysis & Control<br />

52<br />

54<br />

56<br />

Six key trends for the food and beverage market from Mintel<br />

Mintel, the world’s leading market intelligence agency has announced the six key trends set to impact the global<br />

food and drink market – highlighting ingredient and food and drink product trends set to make an impact over the<br />

coming year.<br />

Mintel<br />

Unique requirements for product inspection<br />

Eagle Product Inspection (Eagle), a leading provider of physical contamination detection and quality assurance<br />

equipment, has just returned from Pack Expo <strong>2016</strong> where it showcased a variety of single and dual energy<br />

inspection systems. Many believe that dual energy is always best – however, there are five factors to consider in<br />

the equation that impact hugely on the choice of technology.<br />

Eagle Product Inspection<br />

Mineral oil residues in food<br />

Potentially harmful to health, components from mineral oil hydrocarbons (MOSH/MOAH) present in the inks and<br />

adhesives used in food packaging may migrate, exposing consumers to risk.Constance Voigt of SGS Institut<br />

Fresenius discusses this topical issue for food manufacturers.<br />

SGS Institut Fresenius<br />

58<br />

64<br />

Company News<br />

Diary Dates<br />

67<br />

Media Plan – <strong>Issue</strong> 1 2017<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

08 industry news<br />

Canola oil may help reduce belly fat and improve metabolic syndrome<br />

Research findings announced at ObesityWeek <strong>2016</strong> suggest canola oil and<br />

high-oleic canola oil can help decrease abdominal fat, which may improve<br />

metabolic syndrome. 1 About 40% of adults in the United States have<br />

metabolic syndrome, a cluster of conditions, including belly fat, that increase<br />

the risk of heart disease, stroke and diabetes.<br />

“These results are likely due to the monounsaturated or ‘good’ fat that make<br />

up a large part of canola and high-oleic canola oil,” notes Penny Kris-<br />

Etherton, Ph.D., R.D., Distinguished Professor of Nutrition at Penn State<br />

University who oversaw the study. “This adds to the growing body of<br />

research that monounsaturated fat may help to decrease abdominal fat and<br />

improve markers of cardiovascular health as well.”<br />

Methodology<br />

Researchers from three research centres, the University of Manitoba and<br />

Laval University in Canada, and Penn State University in the United<br />

States, conducted a clinical trial with 101 participants to compare the effects of five<br />

different types of oil on abdominal fat, including canola oil, high-oleic canola oil, high-oleic canola oil with DHA, a corn<br />

and safflower oil blend, and flax and safflower oil blend. The oils were consumed in smoothies twice a day as part of the<br />

participants’ daily diet. The subjects were randomised to a sequence of the five diets, which they followed for four weeks<br />

at a time with a period of four weeks in between each diet during which they followed their usual diet. All of the<br />

participants had central obesity and at least one additional risk factor for metabolic syndrome – high blood pressure,<br />

blood sugar, triglycerides or low ‘good’ HDL cholesterol.<br />

At the end of the two-year study, researchers saw a significant decrease in abdominal fat mass in those on the canola<br />

and high-oleic canola oil diets. In addition, they found a decrease in blood pressure linked to consumption of these oils.<br />

The research was one of five studies selected for publication in a special section of the November <strong>2016</strong> Obesity journal<br />

to provide the latest insights into preventing and treating obesity through innovative research designs. The results of this<br />

study are part of the Canola Oil Multicentre Intervention Trial (COMIT) and were initially presented at the American<br />

Heart Association’s EPI/NPAM Scientific Sessions in New Orleans in 2013.<br />

“Reducing abdominal fat is a great first step to improving the other risk factors associated with metabolic syndrome,<br />

including a decrease in blood pressure, blood sugar and triglycerides, and an increase in HDL cholesterol,” says Kris-<br />

Etherton. “This evidence suggests that using an everyday oil predominantly made up of monounsaturated fat, like canola<br />

oil, could help to have a significant impact on public health.”<br />

Classic canola oil not only contains mostly monounsaturated fat (63g/100g fat), but it also has the least saturated fat<br />

(7g/100g fat) and most plant-based omega-3 fat (9g/100g fat) of any common cooking oil. High oleic canola oil has 73<br />

grams monounsaturated fat per 100 grams fat and is widely used in restaurants, institutions and packaged food<br />

products. n<br />

Source CanolaInfo; http://www.canolainfo.org<br />

The Food and Drink Federation (FDF) unveils a new visual identity<br />

After more than twenty years based in Catherine Street in London’s Covent<br />

Garden, FDF is now operating from the 6th floor at 10, Bloomsbury Way, WC1A<br />

2SL. To coincide with the move, FDF has launched a new visual identity. A new<br />

logo has been developed by design consultancy Ellipsis, following extensive<br />

consultations with staff and members to ensure the essence of the organisation<br />

was properly reflected.<br />

The new identity sees FDF’s core colours move from red to blues and the line<br />

‘Passionate about food and drink’ will also be incorporated. This was found to be<br />

the ‘DNA’ of FDF and its members. The new logo and palette are fully reflected in the design and décor of the new FDF<br />

offices. The Scottish Food and Drink Federation will henceforth be known as FDF Scotland and their new logo reflects<br />

this. They will use the same colour palette and their web url will shortly change to fdfscotland.org.uk n<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

industry news<br />

09<br />

South Sudan to face escalating food<br />

crisis in 2017<br />

As the conflict in<br />

South Sudan<br />

grinds on, the<br />

United Nations<br />

Food and<br />

Agriculture<br />

Organization<br />

(FAO) has warned<br />

that 31% of the<br />

country’s<br />

population, or 3.7 million people, are facing a severe<br />

food security risk, despite the end of the lean food<br />

season and start of harvests – a major increase from the<br />

one million who were in a similar situation last year.<br />

This time of year in South Sudan, people generally are<br />

more secure due to higher food stocks and lower market<br />

prices, but the FAO warned that the risk of famine is<br />

looming, especially for the most vulnerable communities.<br />

“The renewed violence has had severe repercussions on<br />

agricultural production and stability needs to be restored<br />

to enable farmers to return to their fields,” said Serge<br />

Tissot, FAO representative.<br />

“We are seeing an unprecedented number of food<br />

insecure people at harvest time and many more people at<br />

risk of starvation in the months to come as stocks run<br />

out. There is a need to act now to prevent a<br />

catastrophe,” he urged.<br />

Since the start of the fighting in Juba (the capital) and<br />

elsewhere in the country, cereal prices have increased by<br />

more than 500% in only a year. Rampant insecurity along<br />

main roads has crippled trade and traders’ abilities to<br />

access hard currency for imports. Many have been forced<br />

to shut down their businesses.<br />

“With the market collapsing and many families having<br />

little to no safety nets to cope, we must empower them<br />

with the means to produce their own food. With this we<br />

want to structurally strengthen their livelihoods and<br />

boost their resilience,” explained Mr. Tissot.<br />

In the coming dry season campaign, FAO intends to<br />

distribute vegetable and fishing kits as well as training to<br />

farmers on modern farming techniques for 1.2 million<br />

people. Meanwhile, the organisation is gearing up to<br />

respond to the country’s most dire needs for the main<br />

planting season, including providing needed agricultural<br />

inputs in order to enable the most vulnerable citizens to<br />

continue to produce their own food. FAO will require an<br />

additional US$28 million by the end of <strong>2016</strong> to<br />

accomplish these goals. n<br />

Food safety testing market size worth<br />

over US$15bn by 2024<br />

The food safety testing market was worth over US$9bn in<br />

2015, increasing with estimated gains at over 7%,<br />

according to a new research report by Global Market<br />

Insights, Inc.<br />

Stringent regulatory<br />

compliances from<br />

FDA and REACH,<br />

owing to outbreaks<br />

of food-borne<br />

diseases, are<br />

driving the market.<br />

Food supply<br />

globalisation is<br />

one of the key<br />

factors increasing<br />

crosscontamination<br />

levels and fuelling<br />

industry growth.<br />

Key insights from the report include:<br />

n The US food safety testing market has witnessed<br />

significant gains. Policy developments by the Food<br />

Safety and Inspection Service (FSIS) pertaining to<br />

labelling and ensuring national commercial supply<br />

have encouraged regional industry growth.<br />

n Pesticides accounted for over US$800m in 2015.<br />

n The rapidly changing technology market will generate<br />

over US$7bn by 2024. This is because of more<br />

accuracy in monitoring type, count, and metabolites<br />

micro-organisms related to product preservation,<br />

spoilage, safety and fermentation.<br />

n Immunoassay, PCR-based techniques, ELISA, rapid<br />

culture detection and biosensors are key featured<br />

rapid technologies.<br />

n Unhygienic conditions while skinning and handling<br />

animals are key factors for the meat & poultry food<br />

safety testing market. The segment generated close<br />

to US$2bn in 2015.<br />

n China will see growth of >11% due to rising<br />

regulations pertaining to product importation in<br />

Europe and North America.<br />

n Good Agricultural Practices (GAP), Good<br />

Manufacturing Practices (GMP), Good Hygiene<br />

Practices (GHP), and Hazard Analysis Critical Control<br />

Point (HACCP) are key factors stimulating industry<br />

growth. n<br />

Source: UN News Centre<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

10 industry news<br />

New gluten free foods: growing at a fast rate<br />

It’s almost impossible to hear news related to gluten-free foods without also<br />

hearing about how most Americans don’t have celiac disease or even a gluten<br />

sensitivity and are essentially wasting money on an unnecessary fad.<br />

What’s sometimes missed is that a number of Americans simply want to<br />

go gluten-free because the effort contributes to their sense of mental<br />

and physical wellness, according to market research firm Packaged<br />

Facts in a brand new report: Gluten-Free Foods in the U.S. 6th Edition.<br />

“Much like veganism and flexitarianism or going low-carb or dairy-free,<br />

avoiding gluten has become a true lifestyle choice for many Americans,”<br />

says David Sprinkle, research director, Packaged Facts. “These<br />

consumers may not have a specific health-related motive necessitating the<br />

switch to gluten-free. Yet for gluten-free advocates there’s often a satisfaction from furthering one’s overall health and<br />

nutrition goals. Wellness, as they say, begins in the mind.”<br />

These dedicated gluten-free dieters have helped the gluten-free foods market demonstrate an annual growth rate of 36%<br />

over the five-year period ended in 2015, when the market reached US$1.6 billion, according to Packaged Facts and based<br />

on the specific categories analysed for the report. The company forecasts the gluten free foods market will reach US$2<br />

billion in 2020<br />

Gluten-free foods are gaining popularity partly because manufacturers and marketers are aligning new product<br />

developments with other emerging trends in the food and beverage industry. These trends include clean labels, marketer<br />

transparency, and the use of plant proteins and ancient grains.<br />

Clean label and transparency trending<br />

A predominant trend in gluten-free product development reflects the concerns of the clean eating/clean-label movement,<br />

eg, fewer and simpler ingredients; free-from formulations; minimally processed with organic, sustainable production<br />

methods; and transparency in business practices. Makers of gluten-free bean pasta are standouts in the promise of fewer<br />

and simpler ingredients, an attribute that is touted on product packages and on brand websites from the likes of Tolerant<br />

Foods, Gold Harbor, Simply 7 Snacks and Explore Cuisine. n<br />

Source: www.packagedfacts.com.<br />

Liquid packaging market growth dominated by APAC<br />

The market size for liquid packaging is projected to reach US$370.75bn by 2021, registering a CAGR of 5.4% between<br />

<strong>2016</strong> and 2021, driven by high demand from the food & beverages industry, while flexible liquid packaging is the fastestgrowing<br />

liquid packaging type globally.<br />

Increasing demand from the food & beverages industry is the major driver for the liquid packaging market. The global<br />

liquid packaging industry is expected to rise with the increasing demand from food & beverage industry in economies such<br />

as India, China, Africa, Middle East, Germany, Brazil and others. Increasing carbon footprint<br />

due to the use of various resins in the manufacturing of liquid packaging type is the major<br />

restraint affecting the growth of the market.<br />

Flexible liquid packaging is the fastest-growing liquid packaging type. This packaging<br />

type provides various advantages such as longer shelf life, less cost, consumer<br />

friendly, capable of retaining freshness of products, less energy consumption, green<br />

packaging, and others. Films are the largest flexible liquid packaging type used mainly<br />

in the packaging of liquid products. Liquid packaging is widely used as it prevents the<br />

loss of moisture or protects the goods from moisture; improves tear, scuff and puncture<br />

resistance; and provides a heat-sealable surface; and so on.<br />

Asia-Pacific is the largest market for liquid packaging globally, with China being the most<br />

dominant market. This region is also anticipated to witness the highest growth rate,<br />

which is attributed to the rapid economic expansion in the region. n<br />

Source: reportsnreports.com/market-research/manufacturing<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

industry news<br />

11<br />

EFSA publishes two new guidance documents<br />

EFSA has published two guidance documents on novel food and traditional food from third countries to help ensure that<br />

these foods are safe before risk managers decide whether they can be marketed in Europe.<br />

EFSA developed the guidance following the adoption of the new European regulation on novel food in November 2015.<br />

The regulation, which replaces the previous one from 1997 and comes into effect in January 2018, introduces a<br />

centralised assessment and authorisation procedure. EU risk managers will decide on the market authorisation of novel<br />

foods and may ask EFSA to conduct a scientific risk assessment to confirm their safety.<br />

What are novel and traditional foods?<br />

Novel food refers to food that European citizens have not consumed to a significant<br />

degree prior to May 1997. It includes food from new sources (eg oil rich in omega-3<br />

fatty acids from krill), food obtained through the application of new technologies (eg<br />

nanotechnology) or by using new substances (eg phytosterols or plant sterols).<br />

Traditional food is a subset of novel food. The term relates to food traditionally<br />

consumed in countries outside the EU. It includes foods made from plants,<br />

microorganisms, fungi, algae and animals (eg chia seeds, baobab fruit, insects, water<br />

chestnuts).<br />

Guidance on requirements<br />

The new guidance documents explain in detail the kind of information applicants need to provide for risk assessment.<br />

They also clarify how to present this information before EFSA can assess the safety of the novel or traditional food.<br />

Applicants submitting novel food applications need to present data describing the product. Dossiers should include data<br />

on the compositional, nutritional, toxicological and allergenic properties of the novel food as well as information relating to<br />

the production process, and the proposed uses and use levels.<br />

EFSA addresses traditional food from third countries (non-EU countries) in a separate guidance document. Applicants<br />

need to present evidence of safe use of the traditional food in at least one country outside of the EU for a period of at<br />

least 25 years. EFSA and Member States will assess the evidence in parallel procedures. n<br />

Food Banks Canada releases HungerCount <strong>2016</strong><br />

The number of people accessing Canadian food banks increased for the third<br />

consecutive year in <strong>2016</strong>, and is now 28% higher than before the 2008-2009<br />

recession, according to a national study released by Food Banks Canada.<br />

In total, 863,492 people received food from a food bank in March <strong>2016</strong>; 307,535<br />

were children – more than one-third of all people accessing the service.<br />

Food banks in Alberta, Saskatchewan and Nova Scotia led the national increase.<br />

These provinces each experienced jumps of 20% in the number of people accessing<br />

food banks in March <strong>2016</strong> as compared to 2015.<br />

“No one should need to access a food bank in a country as prosperous as Canada,” said<br />

Shawn Pegg, Director of Policy and Research at Food Banks Canada, which coordinated the<br />

national study involving more than 4,000 food programs. “The fact that more than 860,000 people access a food bank<br />

each month shows that we need to break from the past in our approach to hunger and poverty.”<br />

HungerCount <strong>2016</strong> makes policy recommendations to federal, provincial and territorial governments to reduce the need<br />

for food banks. These include:<br />

n The adoption of a national poverty reduction strategy, with measureable targets and adequate funding, by 1 October<br />

2017.<br />

n Changes to social assistance to reduce food insecurity and increase labour force participation.<br />

n Real steps toward a basic income in Canada.<br />

n Investments to address the shocking levels of food insecurity in Northern Canada.<br />

“We were pleased to see federal improvements to both child benefits and pensions in the past year,” continued Pegg. “The<br />

HungerCount shows, however, that there is still much more to be done.” n<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

12 industry news<br />

Prebiotics market to 2020<br />

According to a new report, the global prebiotic ingredients market is projected to<br />

reach US$6.91bn by 2022, at a CAGR of 11.6% from 2017.<br />

Prebiotics are widely accepted ingredients in food & beverage applications owing<br />

to their functional properties. Prebiotic ingredients stimulate the growth and<br />

maintain gut microbiota, which is beneficial for humans. It is highly used in food &<br />

beverage applications and to add nutritional value to several food products. With<br />

the advances in food technology, the requirement of prebiotic ingredients has<br />

grown at a substantial rate over the past decade. Inulin, oligosaccharides such as<br />

FOS, MOS, and GOS have expanded the application areas of prebiotic<br />

ingredients in the food & beverage, animal feed & dietary supplements, thus driving the overall market for<br />

prebiotic ingredients.<br />

Inulin projected to be the largest segment<br />

Inulin accounted for the largest market share in the prebiotic ingredient market in <strong>2016</strong>, due to its wide range of<br />

applications in the food & beverage and animal feed & dietary supplements industries. Inulin can be extracted from a wide<br />

variety of sources such as wheat, bananas, asparagus, garlic, sunchoke and chicory and finds uses in a wide range of food<br />

applications such as dairy products, confectionery products, milk desserts, yoghurt, cheese, baked goods, ice cream and<br />

sauces.<br />

Food & beverages: the most widely preferred prebiotics application<br />

The food & beverages segment accounted for the largest share in the prebiotic ingredients market in terms of value, in<br />

<strong>2016</strong>. The multi-functional nature of prebiotic ingredients, ease of incorporation in a wide range of applications and<br />

increase in health consciousness among consumers are the key drivers of the prebiotic ingredients market. With the<br />

increase in awareness about health & nutrition products among the global population, wide applications in prebiotic<br />

ingredients and positive investigations for health benefits create a platform for newer applications of prebiotics, which<br />

drives the increasing demand and market growth for prebiotic ingredient-based food products.<br />

Europe estimated to be the most lucrative market for prebiotic ingredients<br />

In <strong>2016</strong>, the Europe region held a significant share in the global prebiotic ingredients market and Asia-Pacific is projected<br />

to grow at the highest CAGR during the forecast period. Positive investigations for health benefits create a platform for<br />

newer applications of prebiotics and increase consumer awareness regarding value-added products. n<br />

Source: ‘Prebiotic Ingredients Market by Type (Oligosaccharides, Inulin, and Polydextrose), Application (Food & Beverages, Dietary Supplements, and<br />

Animal Feed), Source (Roots, Grains, and Vegetables), and Region - Global Forecast to 2022’; www.marketsandmarkets.com.<br />

Vitamin D: EFSA sets dietary reference values<br />

EFSA has set dietary reference values (DRVs) for the intake of vitamin D. EFSA provides this<br />

advice to risk managers in European countries who use it for making recommendations to<br />

consumers.<br />

The Panel on Dietetic Products, Nutrition and Allergies (NDA) defined an adequate intake (AI)<br />

of15µg per day for healthy individuals over one year of age. This includes pregnant and<br />

lactating women. The DRVs for infants aged 7–11 months have been set at 10µg per day.<br />

The setting of DRVs for vitamin D is part of the review of reference values for nutrients and<br />

energy intakes established in 1993. It helps risk managers make specific recommendations on the<br />

intake of nutrients to enable European consumers to make healthy diet choices.<br />

Vitamin D can also be synthesised in the body by exposure to the sun, reducing the amount of vitamin D needed via the<br />

diet. The DRVs for vitamin D are based on the assumption of minimal exposure to the sun with resulting limited levels of<br />

synthesised vitamin D. The DRVs will ensure that European consumers take in sufficient levels of vitamin D irrespective<br />

of their geographic location and exposure to sun light.<br />

Vitamin D plays an important role in the body, in particular by helping to maintain normal bones and muscle function.<br />

Vitamin D deficiency may have a negative impact on bone density, resulting in soft bones in children (rickets) and fragile,<br />

misshapen bones in adults.<br />

EFSA recommends further research on the impact of dietary intake and skin synthesis of vitamin D. n<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

industry news<br />

13<br />

There’s ‘November’ been a better time to add 8 strawberries to your diet<br />

Today, nearly 5.4 million Americans are living with Alzheimer’s disease, and diabetes causes more deaths in the US per<br />

year than breast cancer or AIDS combined, according to the American Diabetes Association. November is National<br />

Alzheimer’s Disease Awareness Month and American Diabetes Month and a good<br />

time to remind consumers that studies show adding strawberries to the daily diet<br />

may improve cognitive function and help diabetes.<br />

Strawberries & cognitive function<br />

New research conducted at the USDA Human Nutrition Research Center on Aging<br />

at Tufts University and presented to the Society for Neuroscience revealed that<br />

strawberries might effectively combat age-related cognitive decline. In clinical<br />

studies, USDA researchers demonstrated that supplementing older adults’ diets<br />

with about two cups a day of strawberries could improve cognition even in the<br />

absence of neurological dysfunction.<br />

Strawberries & diabetes<br />

The American Diabetes Association (ADA) identifies berries, including<br />

strawberries, as one of the top ten superfoods for a diabetes meal plan because they are low in sugar (just 7g), calories<br />

(just 45 calories), packed with vitamins (more vitamin C per serving than an orange), antioxidants and dietary fibre (3g).<br />

Additional clinical research suggests that eating a serving of eight medium strawberries a day may improve heart health<br />

and reduce the risk of some cancers. When added up, strawberries provide a nutritious boost for the entire body. Eating<br />

eight strawberries a day is a good habit to develop to improve overall health and guard against disease.<br />

As one of the most versatile fruits – and a delight for the taste buds – strawberries are easy to enjoy daily just as they<br />

are, or in a variety of simple, savoury or sweet recipes. n<br />

Source: California Strawberry Commission<br />

World Heart Federation previews global roadmap to tackle cholesterol<br />

In the Roadmap, the WHF calls for more awareness of healthier lifestyles: increased<br />

screening for cholesterol; more effective drug treatments; better treatment for patients<br />

with familial hypercholesterolaemia (FH); better physician education; and reform of drug<br />

availability and affordability.<br />

The Cholesterol Roadmap forms part of a series produced by WHF to help meet targets<br />

set by the World Health Organization (WHO) to reduce premature deaths from noncommunicable<br />

diseases, including cardiovascular disease (CVD), by 25% by 2025.<br />

Reducing the risk of cholesterol-related CVD has an essential role to play in achieving<br />

this goal.<br />

Professor David Wood, President Elect of the World Heart Federation, said: “Our<br />

Roadmap initiative aims to help international efforts to beat cardiovascular disease. We<br />

have focused on the main CVD risk areas and produced the Roadmaps to help support<br />

individual countries in implementing appropriate health measures.”<br />

Cholesterol is a fat-like substance that is found in all cells of the body. If too much ‘bad’ cholesterol builds up in the<br />

arteries, it can restrict blood flow, increasing the risk of heart attack and stroke. Cholesterol levels vary enormously<br />

between populations, but the traditional Mediterranean diet will lower average cholesterol levels.<br />

For primary prevention WHO recommends identifying people at high risk of having a heart attack and stroke, but most<br />

people are unaware of their cholesterol levels or their overall cardiovascular risk. For patients who already have CVD<br />

reducing cholesterol is important. But a large treatment gap exists in proportions of patients achieving national targets for<br />

cholesterol lowering.<br />

Carlos Castro, Executive Director of the patients’ heart health association, PACO said: “There are more than 17 million<br />

deaths caused by cardiovascular disease each year. High levels of cholesterol are known to increase the risk of heart<br />

attacks and strokes. We hope by tackling the ‘roadblocks’ with the solutions set out in this Roadmap we can reduce the<br />

number of deaths.” n<br />

Source: World Heart Federation<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

14<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

Hi Europe & Ni <strong>2016</strong><br />

29 November–1 December<br />

Frankfurt, Germany<br />

Hi Europe & Ni <strong>2016</strong> offers priceless industry knowledge across a wide range of presentations,<br />

guided tours and showcases. Below are some of the special features that make the show so<br />

important to our industry.<br />

Innovation tours<br />

Join a guided tour led by the experts at Nutrimarketing<br />

on one of the themes below. Meet the exhibitors who<br />

are responding to the latest trends in health and<br />

nutrition through innovation and hear from the<br />

companies themselves about their new products. Learn<br />

about the different applications to see how they could<br />

benefit you and your business.<br />

Sports nutrition<br />

Consumers are more and more interested in sport and<br />

physical activity as a way to improve their health and<br />

lifestyle. Sport nutrition includes products and drinks<br />

that prepare the body, enhance performance or help<br />

people to recover after intense training. This tour will<br />

focus on ingredients for muscle growth, joints, bones or<br />

heart health, but also ingredients for hydration or long<br />

lasting energy.<br />

Life stages<br />

The 1,000 days between a woman’s pregnancy and her<br />

child’s second birthday has a huge impact on his/her<br />

health later on life. A lot of scientific studies have<br />

pointed out the importance of nutrition early in life to<br />

enjoy healthier ageing. At the other end of the<br />

spectrum, the ageing population are focused on staying<br />

active for longer and the food industry is developing<br />

products to meet this need. This tour will focus on new<br />

ingredients for nutrition during pregnancy (in utero<br />

nutrition) and infant nutrition, right through to products<br />

for healthy ageing.<br />

Plant ingredients: greens are the new black!<br />

Superfoods, superfruits, forgotten vegetables, pulses,<br />

ancient grains and algae are just a few of the<br />

ingredients and foods benefiting from this trend. This<br />

tour will showcase the latest innovation and product<br />

development and give you inspiration as to how you can<br />

expand your portfolio. With increasing health and<br />

sustainability concerns around animal based products,<br />

an increasing number of consumers are seeking viable<br />

plant based alternatives to meat and dairy products. As<br />

the global meat substitute market is estimated to grow<br />

by 6.4% CAGR between 2015 and 2020 and the global<br />

dairy alternative market expected to grow by 15.5%<br />

each year until 2020, it is no wonder that the industry is<br />

increasingly taking note of this global and lucrative<br />

trend.<br />

Gut health<br />

Known as our ‘second brain’, our gut is the centre of<br />

our digestive and immune systems. This tour will focus<br />

on digestive heath with popular ingredients such as<br />

probiotics, prebiotics, fibres and digestive enzymes, but<br />

also immune health with ingredients that enhance our<br />

natural defences (vitamins, minerals, plants).<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

show preview: Hi Europe & Ni <strong>2016</strong> 15<br />

New Products Zone<br />

Discover an extensive selection of the most innovative products, showcased alongside insightful information. The<br />

Innovation Zone showcases product innovations from leading industry players. It will provide the perfect opportunity<br />

to give new ingredients the introduction they deserve to the market. A popular area for visitors and the press, this<br />

feature has become a trendsetting spot for the nutrition industry. Below are just a few examples.<br />

AstaReal, Sweden: AstaReal ® Ever-Sharp Effervescent<br />

Boost your mental sharpness and fight tiredness with this unique anti-fatigue<br />

formulation combining AstaReal ® astaxanthin, vitamin B6, B12 and<br />

magnesium. AstaReal has expertly developed Ever-Sharp in a great tasting and<br />

convenient effervescent tablet. Available for private label.<br />

FrieslandCampina Domo: Vivinal Milk Fat blends<br />

Vivinal Milk Fat blend 30 and 65 enable you to compose an optimal fat<br />

composition and structure in infant nutrition. The infant grade fat blends<br />

comprise Vivinal Milk Fat and a tailored vegetable oils mixture. The blends are<br />

100% palm oil-free, which helps in formulating palm oil-free recipes and to<br />

reduce levels of 3-MCPD fatty acid esters.<br />

Stand No.<br />

B41<br />

Stand No.<br />

3H24<br />

Gee Lawson Ltd: OptiMSM ®<br />

OptiMSM ® is branded, scientifically researched form of MSM, manufactured in<br />

the US. in a single-purpose production facility.<br />

What is New? A variety of research indicates MSM (OptiMSM ® ) may play an<br />

important role in supporting the innate immune system. A new scientific review<br />

explores the various influences OptiMSM ® has upon the immune system, and how such<br />

influences may help to mitigate negative outcomes, resulting from chronic stressing of<br />

immune system function.<br />

Ingredia: PRODIET Fluid<br />

PRODIET Fluid is native micellar casein which contains more than 87% protein<br />

on dry matter. This unique micellar casein has been specifically developed to<br />

formulate very high protein beverages while retaining a perfect fluidity.<br />

PRODIET Fluid has a delicious milky taste, a high nutritional quality (rich in<br />

branched chain amino acid and in leucine) and is UHT stable.<br />

PRODIET Fluid combines technical and nutritional functionalities: it enables the<br />

development of meal replacement with more than 10% protein content while keeping<br />

incredible fluidity, smooth texture and a perfect taste.<br />

Tate & Lyle Oat Ingredients: PromOat ® Beta Glucan<br />

PromOat ® Beta Glucan from Tate & Lyle is a unique heart-healthy and natural<br />

oat fibre ingredient that can give access to front-of-pack cholesterol-lowering<br />

and heart health claims in many countries around the world, including the EU.<br />

PromOat ® enriches foods, beverages and supplements with the goodness of oats,<br />

and is easy to formulate due to its solubility and clean taste.<br />

Stand No.<br />

A25<br />

Stand No.<br />

J20<br />

Stand No.<br />

B1<br />

Volac International Ltd: Volactive ® ProCrisp Medium<br />

ProCrisp Medium is the latest addition to the Volactive ® range of high protein<br />

solutions. Containing over 50% protein and made from Volactive ® UltraWhey<br />

90 with added rice flour, ProCrisp Medium has all the goodness of ProCrisp<br />

Small but offered in a larger size (up to 6mm). It’s the perfect solution to<br />

snacking on-the-go and protein fortification.<br />

Stand No.<br />

D40<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

16<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

The conference<br />

The Hi Europe Modular Conference brings together<br />

leading industry experts for you to meet, learn from and<br />

network with. Over three days the Hi Europe modular<br />

conference will address the biggest challenges and<br />

hottest trends in the food industry over 18 highly<br />

focused modules. Use our flexible package options to<br />

create your own bespoke programme and ensure you<br />

gain the knowledge and make the connections you need<br />

to see your business flourish in the coming year.<br />

NEW Full day conference: The Future of Nutrition<br />

Get a head start on the competition this year by<br />

attending our full day conference on The Future of<br />

Nutrition, taking place the day before Hi Europe opens<br />

on 28th November. Gain insights into the gamechanging<br />

trends that will shape the health ingredients<br />

industry in the coming years.<br />

NEW Ingredients in Action<br />

The Ingredients in Action pavilion tasting bar allows<br />

visitors to taste, touch and smell the latest products.<br />

Innova Market Insights will present over 10 highly<br />

innovative healthy products for sampling. Highlights at<br />

last year’s tasting bar at Fi Europe 2015 included a<br />

functional beverage with spirulina, various energy<br />

drinks with unusual flavours (eg cinnamon), coconut<br />

chips, a juice meal alternative with coconut milk for<br />

satiety, and a snacking bar made with cricket<br />

protein. Expect a whole host of innovative surprises at<br />

this year’s bar too, including high protein snacks and<br />

sports performance solutions. So be sure to drop by<br />

and sample the best of what the nutrition industry has<br />

to offer.<br />

Today’s consumers have become more<br />

concerned than ever about what they<br />

are eating and are actively seeking<br />

healthy, natural and functional foods<br />

Start-up Innovation Challenge<br />

The most exciting innovations are coming from small<br />

start-ups who are largely unknown to the wider<br />

industry. We are giving a handful of start-ups the<br />

chance to share their research and pitch their latest<br />

innovations live at Hi Europe & Ni. Our panel of industry<br />

judges will select the company with the most exciting<br />

idea as winner of the Start-up Innovation Challenge.<br />

Join us at the Industry Insight Theatre on the afternoon<br />

of 29 November to meet these true innovators of the<br />

industry.<br />

Specialised Pavilions/Zones<br />

Our dedicated pavilions will help you find the<br />

targeted solutions and ingredients your business<br />

needs:<br />

n Expo FoodTec<br />

n Organic<br />

n Free From<br />

n Ni<br />

n GOED (Omega 3 Pavilion)<br />

Expo FoodTec<br />

In talking to our global audience over the past year,<br />

we’ve seen an increasing demand worldwide for<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

show preview: Hi Europe & Ni <strong>2016</strong>HiE Preview 17<br />

solutions in processing, packaging, equipment, R&D,<br />

contract manufacturing, food safety and services. To<br />

accommodate this, Hi Europe <strong>2016</strong> is introducing the<br />

Expo FoodTec pavilion. The Expo FoodTec Pavilion was<br />

launched at Food ingredients Europe in 2015 and we<br />

are pleased to now introduce it to Hi Europe. The Expo<br />

FoodTec Pavilion is your answer to a one-stop shop for<br />

sourcing solutions for your complete range of needs!<br />

Review of the last edition<br />

Health ingredients Europe 2014 was the biggest and<br />

best to date, with attendees growing a staggering 20%<br />

from the previous edition, cementing its place as<br />

Europe’s leading health, natural and nutritional<br />

ingredients platform.<br />

From 2–4 December 2014, more than 450 leading<br />

exhibitors such as DSM, Naturex, Beneo, Gelita,<br />

DuPont Nutrition & Health, plus many more, were<br />

present on the show floor, showcasing their latest<br />

innovations in the world of health, natural and<br />

nutritional ingredients. More than 8000 attendees from<br />

93 different countries gathered in Amsterdam to source<br />

from the 4,651 ingredients at the show, to network with<br />

industry colleagues and to learn about new processes,<br />

technologies and industry trends.<br />

Today’s consumers have become more concerned than<br />

ever about what they are eating and are actively<br />

seeking healthy, natural and functional foods. This was<br />

clearly reflected at the show with the most sought after<br />

ingredients being proteins, plant extracts, functional<br />

foods, flavourings and nutraceuticals. Visitors to the<br />

show included professionals from companies such as<br />

Mars, Pepsico, Coca Cola, Unilever, Danone, Nestlé<br />

and Heinz, once again highlighting the importance of<br />

health ingredients to the industry. 76% of these visitors<br />

held their company’s purchasing power, with 36% being<br />

c-suite level executives.<br />

The Health ingredients Europe show floor was also<br />

buzzing with features and educational programmes. A<br />

total of 2,095 attendees attended the seminar sessions,<br />

industry insights theatres, innovation tours and<br />

conferences, with the most popular topics being weight<br />

management, trends, sugar reduction and protein<br />

alternatives. New to Hi Europe was Fi TV, which<br />

generated much talk around the halls, with live<br />

interviews from the show floor, and live social media<br />

broadcasting. Health ingredients Europe <strong>2016</strong> will<br />

return to Frankfurt, Germany, one of the leading<br />

European cities in the food and beverage industry. From<br />

29 November – 1 December <strong>2016</strong> it will bring together<br />

once again the largest congregation of health, natural<br />

and nutritional professionals together, under one roof. n<br />

HiE & Ni <strong>2016</strong><br />

www.figlobal.com/hieurope<br />

ubm.figlobal.com/Natural/Ingredients<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

18<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

BENEO: Taking sugar replacement to the next level<br />

BENEO will be focusing on the physiological effects of sugar<br />

replacement and the importance of looking ‘beyond the label’. In<br />

keeping with this theme, BENEO will be showcasing a variety of<br />

samples on its stand that take sugar replacement to the next<br />

level, using ingredients that have a sugar-like indulgent taste and<br />

texture that consumers expect, but also contribute to balanced<br />

blood sugar levels and more.<br />

Beyond the label<br />

More than 70% of the European consumers try to cut their<br />

sugar intake and 58% of them do so because they want to<br />

control their weight. Unsurprisingly, solutions with less sugar<br />

are a major focus for many food and drink producers at<br />

present. However, the current discussion about sugar reduction often ignores the<br />

fact that blood sugar management plays a key role in weight management. Whilst high glycaemic ingredients,<br />

such as maltodextrin, help to reduce the sugar because they are oligo- or polysaccharides (and not mono- or<br />

disaccharides), they nevertheless have a significant impact on a person’s metabolism. Over time, the human<br />

blood glucose regulation system can become imbalanced, leading to pre-diabetes and diabetes, accompanied<br />

by overweight conditions.<br />

At HiE <strong>2016</strong>, BENEO will demonstrate how its naturally sourced chicory fibres and functional carbohydrates<br />

can replace commonly known sugars and maltodextrin, while also lowering blood glucose responses (a benefit<br />

that has been confirmed by the European Commission with a respective EU health claim) and providing a<br />

natural taste with a mild sweetness that consumers are looking for. n<br />

Stand<br />

J10<br />

www.beneo.com<br />

Glatt Ingenieurtechnik GmbH: State-of-the-art<br />

fluidised and spouted bed technologies<br />

Glatt Ingenieurtechnik GmbH will present its state-of-the-art<br />

fluidised and spouted bed technologies for the precise adjustment<br />

of product attributes in food, instant beverages, dietary<br />

supplements and nutraceuticals. The engineering expert and plant<br />

manufacturer offers solutions for sophisticated applications that<br />

require specific particle sizes or shapes, optimum solubility or the<br />

functional protection of active ingredients, for example.<br />

From technical challenges during production, filling or handling to<br />

the problematic development of functional, nutritional or sensory properties,<br />

processing liquid or powdered raw materials can be demanding for food manufacturers and<br />

producers of functional ingredients.<br />

With fluidised and spouted bed technologies, Glatt Ingenieurtechnik will highlight pioneering processes<br />

that influence and adjust product attributes using spray granulation, spray agglomeration, spray coating and<br />

spray encapsulation. To cite an example, vitamins or enzymes can be spray granulated and covered with a film<br />

coating that enables the controlled release of active ingredients at the same time. Furthermore, agglomerated<br />

instant powders that consist of partially hydrophobic components can be formed into readily soluble<br />

compounds that don’t separate and offer homogenous particle size distribution profiles.<br />

Flavours and essential oils can be spray granulated and encapsulated before they receive a protective coating,<br />

which makes them stable during transport and storage, and easy to dose. An additional benefit is the ability to<br />

release active substances in a time-dependent way. The appropriate selection and combination of process<br />

parameters is important here. n<br />

Stand<br />

J72<br />

www.glatt.com<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

show preview: Hi Europe & Ni <strong>2016</strong> 19<br />

Omya: Calcium boosters for foods and drinks<br />

Omya’s high purity calcium carbonate portfolio is suitable for a wide<br />

variety of functional foods – additional ingredients from its<br />

distribution portfolio enable holistic one-stop solutions<br />

Omya will highlight its calcium fortification agent Omya Calcipur® at<br />

HiE. Thanks to its high elemental calcium content of approximately<br />

40%, it is one of the most concentrated sources of calcium in the<br />

market. That makes it possible to use up to five times less of this<br />

ingredient than other available technical solutions, while achieving the same<br />

calcium dose in a finished foodstuff. Fields of application include baby products, vegan drinks, bakery<br />

produce, snack bars and breakfast cereals. Depending on the dosage used, calcium-related claims can<br />

be made on pack.<br />

One of the main advantages of Omya Calcipur® is the low dosage needed for supplementation, resulting in<br />

reduced costs and less impact on the sensory profile of the final foodstuff. Comprising different grades of<br />

natural calcium carbonates, Omya’s portfolio enables manufacturers to produce the best possible results in<br />

terms of nutrition and taste.<br />

“We see growing demand for calcium in the coming years. Because of demographic changes and ageing<br />

populations, experts predict that the number of people suffering from osteoporosis will increase significantly.<br />

But it’s not just the elderly who can benefit from calcium fortification. An increasing number of consumers are<br />

omitting dairy products from their diet,” says Stefan Lander, Vice President Consumer Goods at Omya.<br />

“Offering functional foods that remove the risk of developing calcium deficiency disorders is, therefore, a<br />

hugely important task for the food industry. At HiE, we’ll demonstrate how proper supplementation and<br />

outstanding taste can be combined.”<br />

Thanks to its role as a global distributor, Omya possesses a comprehensive portfolio of versatile ingredients<br />

and provides a wide range of solutions that can be adjusted to customer requirements. Visitors to the booth<br />

can learn about the wide range of ingredients and the company’s expertise of holistic solutions. At the show,<br />

natural food colours, yeast extracts, stevia, vitamins and other food supplements as well as textured soy<br />

protein components will be showcased. n<br />

www.omya.com<br />

Stand<br />

G54<br />

Stable Micro Systems: The newest addition to its portfolio of<br />

texture analysis instruments<br />

The TA.XTplus100 offers a half micron distance resolution, ideal for testing materials<br />

that require fine distance control such as small granules or tablets/capsules.<br />

With an increased focus on health and wellness, consumers are demanding more<br />

convenient and nutritious food. This has led to an increase in reduced sugar or<br />

reduced salt products, but recipe alterations can present manufacturers with a range<br />

of formulation challenges. Texture analysis can be used in new product development<br />

to provide a clear, objective measurement of the effect of recipe changes to ensure<br />

consumer experience is not negatively affected.<br />

Jo Smewing, applications manager at Stable Micro Systems, stated: “We are<br />

delighted to introduce the TA.XTplus100 to the market at HiE <strong>2016</strong>. At Stable Micro<br />

Systems we are dedicated to providing comprehensive texture analysis solutions for our customers. This<br />

science is a vital aspect of both quality control and the development process and, with consumers becoming<br />

more demanding than ever, texture analysis can offer the quality boost needed to gain a competitive edge in the<br />

market.”<br />

In addition to being able to offer an improved distance resolution, particularly beneficial to the nutraceutical and<br />

pharmaceutical industries, the new instrument is also capable of measuring force of up to 100kg, offering an<br />

increased capacity within the same laboratory space. n<br />

Stand<br />

G80<br />

www.stablemicrosystems.com<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

20<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

GELITA: Collagen Proteins Smart Technology<br />

GELITA will present the first in a new series of SMART TECHNOLOGY<br />

solutions: Collagen Peptides ST is a range of enhanced ingredients that<br />

brings an optimised performance level and an improved processing performance<br />

to customers.<br />

Dr Margarethe Plotkowiak, Head of Global Product Management Food at GELITA,<br />

notes: “In new product development, there are often limitations by process<br />

parameters of existing equipment. These difficulties can be related to dissolution<br />

or, for example, undesired foaming. The ST product range was developed to<br />

overcome these hurdles. This not only enables manufacturers to run more stable,<br />

controlled and optmised processes, it also facilitates the creation of new products<br />

without these previous limitations and without investing in new production<br />

facilities.”<br />

Building on GELITA’s existing product range Collagen Peptides ST provide<br />

physiological functionalities and technological functionalities. Both exhibit<br />

improved process performance, namely less dust during handling, fewer<br />

clumping issues during dissolution, improved wettability and higher bulk densities. For the customer,<br />

this means improved production, optimised machinability and the ability to develop new and exciting products.<br />

Potential applications include the fortification of clear, high-protein gummies with a protein content of up to<br />

35%, and as a nutritious binding agent in cereal bars or coated products. The optimised bulk density means it’s<br />

now possible to significantly increase the amount of Bioactive Collagen Peptides ® that, for example, can be<br />

included in a hard capsule shell. Furthermore, depending on the product and process requirements, viscosity<br />

and drying times can be adjusted to provide optimal results. Of course, in line with GELITA’s existing portfolio,<br />

ST products are non-allergenic and can be used to achieve a clean and clear label.<br />

With new products being added to the portfolio on a regular basis, don’t miss this opportunity to discover more<br />

about GELITA’s SMART TECHNOLOGY solutions and its market-leading collagen proteins.<br />

Live on stage<br />

As official sponsor of the Hi Europe Conference (Modul 6A: Healthy ageing: staying active for longer, 30<br />

November, 14:00–15:30), GELITA’s leadership in collagen peptide science is reflected at this year’s event.<br />

During this session, Dr Steffen Oesser, Director, Collagen Research Institute (CRI), will discuss ‘The Collagen<br />

Peptides Story: The Next Chapter’ at 15:00. He will explore how collagen peptides can reduce some of the<br />

side-effects of ageing and help people to lead more active lives for longer.<br />

In addition, Dr. Stephan Hausmanns, Vice President BU Health & Nutrition at GELITA, will present ‘Collagen<br />

Peptides in an Awakening Age of Women’ in the Seminar Theatre (Stand D82) on Wednesday 30 November at<br />

13:30. Topics include the global market for collagen peptides, applications such as beauty from within, and bone<br />

and joint health, their mode of action and supporting science. n<br />

Stand<br />

H14<br />

www.gelita.com<br />

reprints<br />

www.foodmagazine.eu.com<br />

IF YOU ARE INTERESTED IN HAVING REPRINTS OF YOUR ARTICLE TO HAND OUT TO<br />

YOUR CUSTOMERS/ PROSPECTS<br />

please contact: john@foodmagazine.eu.com<br />

IT’S A LOT LESS EXPENSIVE THAN YOU MIGHT THINK<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

show preview: Hi Europe & Ni <strong>2016</strong> 21<br />

Taiyo: Functional solutions for better health<br />

Taiyo GmbH will showcase its wide range of health ingredients. A particular<br />

highlight is Sunfiber ® , an all-natu ral, soluble dietary fibre and one of only five<br />

ingredients to receive ‘True-Fiber’ status from the US FDA. Rich in fibre,<br />

Sunfiber ® exhibits excellent pH, heat and freeze-thaw stability, and is an ideal<br />

ingredient to support a healthy lifestyle. Visitors to Taiyo’s booth will also be<br />

able to experience a wide range of versatile, naturally derived ingredients<br />

that offer both excel lent taste and health-boosting properties. Bursting with<br />

a powerful combination of vitamins, minerals and dietary fibres, the products<br />

can be used to enrich a number of foods, beverages, medical and<br />

pharmaceutical formulations.<br />

© George Doyle<br />

Sunfiber ® improves functionality in foods, beverages, supplements and ready-to-drink applications.<br />

As it’s totally tasteless, odourless and completely soluble in wa ter, Sunfiber ® has no visible effect on<br />

the end product but significantly boosts its health bene fits. It is clinically proven to lower the glycaemic<br />

index, improve mineral absorption, maintain digestive health and is even able to reduce postprandial-blood<br />

sugar peaks in healthy as well as glucose-intolerant people. Sunfiber ® is available in different qualities,<br />

depending on the desired application and claims, including three new organic varieties.<br />

As a pioneer in the research and manufacture of functional ingredients, Taiyo keeps a keen eye on current<br />

market developments and the growing consumer interest in natural ingredients. Whether it’s dietary fibre, tea<br />

or superfruit extracts, or highly bioavailable iron and zinc fortifica tion agents, Taiyo’s versatile portfolio helps<br />

manufacturers to develop innovative prod ucts with a health and wellness positioning.<br />

Hi provides the perfect environment to discover Taiyo’s comprehensive portfolio of functional ingredients. “We<br />

can tailor our ingredients for a wide range of purposes, applications and formulations to meet individual<br />

requirements,” says Dr Stefan Siebrecht, Managing Direc tor of Taiyo. n<br />

Stand<br />

H40<br />

www.talyogmbh.com<br />

Carbery: Innovative protein and flavour portfolio<br />

Carbery Food Ingredients and Synergy Flavours will<br />

present their joint capabilities in innovative proteins and<br />

flavours. In particular, Carbery will be showcasing its<br />

leading range of hydrolysed whey protein, Optipep ® , and<br />

Synergy its bitterness masking solutions, developed to<br />

help customers meet the challenges of the nutrition<br />

market.<br />

Protein, flavour and applications experts will be at the<br />

stand to discuss the opportunities for manufacturers<br />

looking to meet demand for healthy, functional and<br />

nutritious foods and beverages. With consumers<br />

placing greater emphasis than ever before on nutrition,<br />

Carbery and Synergy together can ensure<br />

manufacturers are able to meet the nutritional market needs<br />

of today, and even anticipate future trends.<br />

Visitors to the stand will be able to sample a wide variety of food and beverages that demonstrate the<br />

applications and formulation expertise that is available by working with Carbery and Synergy. In line with<br />

growing market trends for high-protein diets, Carbery will showcase the latest in its dairy protein technology<br />

with beverages and snacks enriched with its hydrolysed whey protein, Optipep ® . In combination with Synergy’s<br />

bitterness masking expertise, manufacturers will be able to see how to optimise the nutritional content of<br />

beverages, while also offering an exceptional taste experience. n<br />

Stand<br />

H63<br />

www.carbery.com<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

22<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

ADM: healthy and nutritious ingredients<br />

WILD Flavors & Specialty Ingredients (WFSI), a business unit of<br />

Archer Daniels Midland Company, will showcase its<br />

comprehensive ingredients portfolio. WFSI will be highlighting its<br />

extensive range of plant-based proteins and fibres, natural<br />

colours and flavours, nutritional ingredients, and high quality<br />

lecithins, designed to help its customers deliver products that<br />

meet demand for nutrition, function, texture and taste.<br />

WFSI’s technical experts will be on stand to discuss the<br />

opportunities available for manufacturers looking to meet customer demand for healthy,<br />

functional and convenient food and beverages. Additionally, visitors will be able to sample a variety of<br />

nutritious and flavoursome food and beverage concepts that demonstrate the broad applications and<br />

formulation expertise WFSI can offer.<br />

With consumers more focused on health and wellbeing than ever before, WFSI’s ingredients can ensure<br />

manufacturers stay ahead of the trend by enhancing the nutrient profile of their products, as well as offering<br />

natural colours and flavours, such as WFSI’s distinctive USP-grade mint oil, to support the industry shift<br />

towards clean label products.<br />

Diets high in protein<br />

In particular, diets high in protein are proving increasingly popular with consumers, leading to a high demand for<br />

protein-fortified food and beverages. WFSI’s protein beverage featuring CLARISOY ® isolated soya proteins will<br />

be available for tasting on stand. CLARISOY ® is ideal for increasing the protein content of beverages without<br />

negatively affecting the taste, colour or acidity of the finished product. This enables manufacturers to meet<br />

consumer demand for added nutritional benefits while also offering an exceptional taste experience.<br />

Eating on-the-go<br />

Modern consumers are also looking for convenient foods that can be eaten on the go. WFSI’s range of protein<br />

bars featuring the Textura range of customised protein crisps, which provide consumers with a convenient<br />

way to increase protein intake, will also be available on stand. Textura crisps are a great source of high quality<br />

protein, fibre and whole grains, and are available in a range of protein contents. Textura crisps can be used in<br />

food products in a cost-effective way to enhance nutrient content, and to provide texture and flavour. Also<br />

included in the bars is Fruit Up, a gluten-free, natural fruit sweetening system suitable for vegetarians and<br />

vegans. n<br />

Stand<br />

G24<br />

www.adm.com<br />

Arjuna: Indian gooseberry Ingredient<br />

Arjuna Natural Extracts Ltd. will launch TRILOW, its Indian<br />

gooseberry (Phyllanthus emblica, aka ‘amla,’) ingredient, a complete<br />

extract of fresh ripe fruits of wild amla, collected seasonally from the<br />

tree.<br />

Arjuna’s unique and proprietary gentle extraction process preserves<br />

ingredient functionality and ensures potency. TRILOW has attained<br />

US patents for its composition, plus has pending patents<br />

worldwide.<br />

Indian gooseberry is a traditional Indian fruit that combines superfruit health benefits with traditional<br />

Indian Ayurvedic formulations. In recent clinical trials, including results from a new study to be released<br />

at Hi Europe, it has demonstrated heart health benefits, including reducing LDL and triglycerides. The<br />

recommended dosage of TRILOW to promote cardiac health is just 500mg twice a day.<br />

Arjuna will also exhibit its leading turmeric extract brand, BCM-95 ® , an all-natural, patented formulation for<br />

supplementing food and beverages. The company will present latest clinical research results of its<br />

OXYSTORM ® standardised nitrate ingredient as well, showing that OXYSTORM could help athletes work out<br />

longer and harder. n<br />

www.arjunanatural.com<br />

Stand<br />

C29<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

show preview: Hi Europe & Ni <strong>2016</strong> 23<br />

Roquette: ‘Creatilicious Bar’ leads the way to<br />

healthier lifestyles<br />

Roquette is to highlight the versatility of its plant-based solutions by<br />

showcasing a selection of exciting new food concepts. Visitors to the<br />

forthcoming expo in Frankfurt will be invited to the company’s new<br />

‘CREATILICIOUS BAR’. There they will taste a menu of delicious new<br />

food concepts specially created by the company’s food application<br />

experts and see first-hand how they address the need for healthier<br />

lifestyles. The exciting ideas on show will include:<br />

n A delicious protein pancake: Easy to prepare, this concept combines multiple<br />

sources of protein – especially NUTRALYS ® pea protein – that contributes to muscle mass maintenance.<br />

n A refreshing and healthier virgin mojito: Thanks to NUTRIOSE ® soluble fibre, this sugar-free cocktail is an<br />

easy & fun way to boost your daily fibre intake.<br />

n Gluten-free crunchy bites: These satisfying high-protein snacks offer visitors a multi-texture experience<br />

thanks to NUTRALYS ® Pea protein and PREGEFLO ® starch.<br />

n High-protein vegan bars: These gluten-free, soft-texture bars are made with NUTRALYS ® pea protein – that<br />

helps support muscle gain and promote satiety.<br />

Visitors will also discover the XTAB polyols: Roquette’s range of directly compressible polyols that offer<br />

multiple technological benefits as well as texture possibilities for sugar-free confectionery tablets. The<br />

company’s other functional plant-based solutions on show will include NEOSORB ® sorbitol; SweetPearl ®<br />

maltitol; and XYLISORB ® xylitol – which offer sweetening power in Toothfriendly confectionery applications.<br />

Roquette generates new opportunities for formulators to deliver innovative, convenient and healthier foods and<br />

nutraceuticals. Its clear-cut, natural-origin solutions open up possibilities in a range of categories, from sports<br />

and weight management food products to healthy sweets. n<br />

Stand<br />

D24<br />

www.roquette.com<br />

Bioactive Collagen Peptides ® stimulate body functions<br />

Body Toning<br />

•<br />

Beauty from Within<br />

•<br />

Joint Health<br />

•<br />

Bone Health<br />

•<br />

Normal<br />

bone<br />

matrix<br />

Connective Tissue<br />

Improvement<br />

•<br />

Osteoporosis<br />

GELITA AG · Uferstr. 7 · 69412 Eberbach · Germany · www.gelita.com<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>

24<br />

show preview: Hi Europe & Ni <strong>2016</strong><br />

Glanbia Nutritionals: Innovative<br />

ingrediens for protein, gluten-free<br />

and immune boosting<br />

application<br />