FoodEurope Issue 4 2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

processing & packaging 43<br />

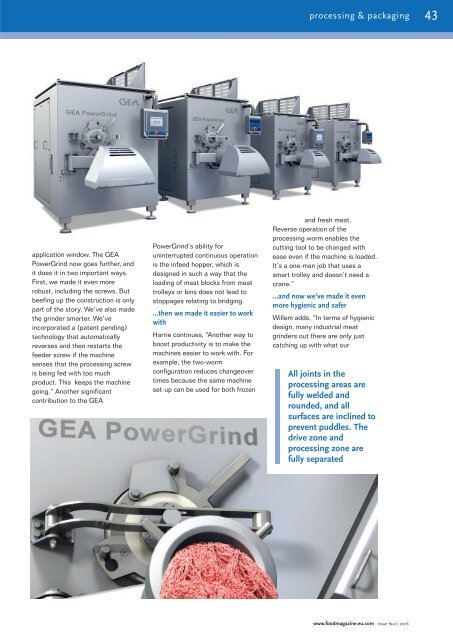

application window. The GEA<br />

PowerGrind now goes further, and<br />

it does it in two important ways.<br />

First, we made it even more<br />

robust, including the screws. But<br />

beefing up the construction is only<br />

part of the story. We’ve also made<br />

the grinder smarter. We’ve<br />

incorporated a (patent pending)<br />

technology that automatically<br />

reverses and then restarts the<br />

feeder screw if the machine<br />

senses that the processing screw<br />

is being fed with too much<br />

product. This keeps the machine<br />

going.” Another significant<br />

contribution to the GEA<br />

PowerGrind’s ability for<br />

uninterrupted continuous operation<br />

is the infeed hopper, which is<br />

designed in such a way that the<br />

loading of meat blocks from meat<br />

trolleys or bins does not lead to<br />

stoppages relating to bridging.<br />

…then we made it easier to work<br />

with<br />

Harrie continues, “Another way to<br />

boost productivity is to make the<br />

machines easier to work with. For<br />

example, the two-worm<br />

configuration reduces changeover<br />

times because the same machine<br />

set-up can be used for both frozen<br />

and fresh meat.<br />

Reverse operation of the<br />

processing worm enables the<br />

cutting tool to be changed with<br />

ease even if the machine is loaded.<br />

It’s a one-man job that uses a<br />

smart trolley and doesn’t need a<br />

crane.”<br />

…and now we’ve made it even<br />

more hygienic and safer<br />

Willem adds, “In terms of hygienic<br />

design, many industrial meat<br />

grinders out there are only just<br />

catching up with what our<br />

All joints in the<br />

processing areas are<br />

fully welded and<br />

rounded, and all<br />

surfaces are inclined to<br />

prevent puddles. The<br />

drive zone and<br />

processing zone are<br />

fully separated<br />

www.foodmagazine.eu.com issue four | <strong>2016</strong>