life - GEA Group

life - GEA Group

life - GEA Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

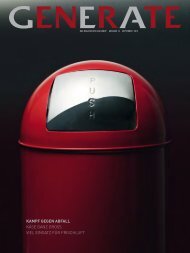

| CompAny<br />

WE’rE GETTING bEttEr All tHE timE!<br />

KAIzEN PrOMOTES VALUE CrEATION.<br />

it all began with the realization that keeping customers is less costly than acquiring new ones.<br />

What can be more appealing to customers than constant, tangible improvement? that’s exactly<br />

what we’re trying to achieve with the aid of our internal advisors gea Consulting gmbH<br />

(see bOx) and the kaizen management system.<br />

The word ‘Kaizen’ in Japanese means improvement. Not all<br />

at once, but step by step, as Asian philosophy teaches us. It<br />

doesn’t mean that everything has to be new and different. We<br />

just want to improve in places where the opportunity presents<br />

itself.<br />

Whatever increases value<br />

It’s a matter of separating the wheat from the chaff. Keep<br />

any activity that increases the value of a product or service,<br />

eliminate those activities that consume resources without adding<br />

any value. The quality of products or services will improve,<br />

services will become prompter and more flexible and costs will<br />

drop. Every process will undergo scrutiny and will be improved<br />

with regard to customer needs.<br />

toyota – a shining example of kaizen<br />

Kaizen is not the latest rage among consulting companies:<br />

Toyota came up with the concept in the 1950s. The Japanese<br />

automobile manufacturer was in a crisis then. However, instead<br />

of shedding 0 per cent of its staff, the company opted<br />

for permanent quality enhancement. They collected methodologies<br />

from the US and Europe, combining them into what<br />

became known as the Toyota Production System. It seems to<br />

have paid off because Toyota passed General Motors in early<br />

2007 becoming the largest automobile manufacturer in the<br />

world.<br />

Extending kaizen to production and administration<br />

We’re not in a crisis but nevertheless we want to provide our<br />

customers with lots of reasons to continue doing business with<br />

us - whether it’s in manufacturing or in administration. While<br />

manufacturing costs continue to drop, administration costs<br />

have risen briskly. Today nearly everyone complains about a<br />

drastic rise in the flood of information. More than an hour<br />

each day is lost just handling email and even more time is<br />

consumed in unfocused meetings. Finally, very few employees<br />

have an eye on the entire process, which means that they do<br />

not realize that their colleagues are their prime customers.<br />

kaizen at <strong>GEA</strong><br />

I²M, on the one hand, solicits individual suggestions for<br />

improvement. Kaizen, on the other hand, aims at systematic<br />

improvement by teams of employees. Workshops in manufacturing<br />

and administration, training sessions, analyses of<br />

potential, plus company visits are all ways to come up with<br />

suggestions for improvement, to verify their feasibility and<br />

then implement them. The result will be a world-class standard<br />

in manufacturing and administration, the best prerequisites for<br />

loyal customers.<br />

gea Consulting gMbH<br />

Guido Beyß and Marco Silz head <strong>GEA</strong> Consulting GmbH. Fifteen<br />

experienced consultants provide support to all <strong>GEA</strong> divisions<br />

and companies across a variety of projects. Services include<br />

strategy, support during acquisition projects, help with investment<br />

considerations including execution and risk management,<br />

as well as zero-based budgeting, corporate restructuring and<br />

process optimization by Kaizen. The emphasis initially is on creating<br />

transparency. <strong>GEA</strong> Consulting GmbH then works with<br />

people to develop concepts, implementing them on site in the<br />

operative units. It combines expertise in process optimization<br />

with know-how specific to <strong>GEA</strong>. As a central internal service,<br />

affiliated to the ressort process technology of the <strong>GEA</strong> Board,<br />

<strong>GEA</strong> Consulting combines expertise in process optimization<br />

with <strong>GEA</strong> specific know-how.<br />

kAi<br />

CHAnGE<br />

ZEn<br />

Good<br />

(for the better)<br />

Kaizen is a composit of the Japanese words ‘kai’ and ‘zen’.<br />

CompAny | 9