life - GEA Group

life - GEA Group

life - GEA Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

STaff<br />

MagaziNE 01<br />

09.2007<br />

<strong>life</strong><br />

THE CoRpoRaTE SToRy / WHaT’S SpECial aboUT gEa<br />

i²M / NEW idEaS THaT SERvE all<br />

THE ColoSSi of ST. NazaiRE / a pHENoMENal pRojECT foR NigERia

12<br />

CONTENT<br />

02<br />

16<br />

CONTENTS<br />

Company<br />

02 The Corporate Story<br />

08 Valorization by Kaizen<br />

10 Buena Vista<br />

Markets<br />

12 The Colossi of St. Nazaire<br />

14 Smoke-free thanks to Clarifair<br />

15 <strong>GEA</strong> at Brau Beviale 2007<br />

16 A factory of superlatives<br />

18 Happy Birthday:<br />

100 years of mineral oil separator<br />

Employees<br />

20 Ready for take-off<br />

21 One click leads to <strong>GEA</strong><br />

22 The <strong>GEA</strong> Allstars – ready to rock<br />

23 New ideas serve all<br />

24 News in brief and Quirks<br />

i²M<br />

26 improvement Management<br />

Dialogue<br />

30 The European Works Council<br />

31 Puzzles · Raffles · Miscellaneous<br />

32 imprint<br />

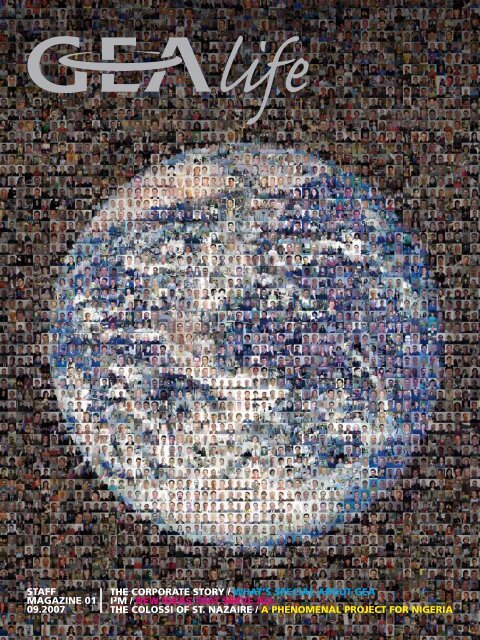

We’re <strong>GEA</strong><br />

<strong>GEA</strong> Life is the magazine<br />

for every member of the<br />

<strong>GEA</strong> <strong>Group</strong> – regardless of<br />

where in the world they are.<br />

The cover of the first issue is<br />

proof of this. Employees were<br />

asked to submit a photo via<br />

MMS or email. The response<br />

was overwhelming. 2,150<br />

people from all over the<br />

world responded. The globe<br />

on the cover is a composite<br />

of all the pictures submitted.<br />

It’s worth taking a closer<br />

look – you might just recognize<br />

yourself or a coworker.<br />

Many thanks for your photos<br />

and for your permission to<br />

print them.<br />

FiNally a MagaziNE<br />

FOr EvEryONE aT gEa.<br />

The <strong>GEA</strong> <strong>Group</strong> is a large company, employing some 19,000 people across the globe.<br />

In an international group of such a scale, it is simply impossible for the employees to<br />

get a complete picture of the entire group with all of its manifold offerings and solutions<br />

for its clients. Many employees, however, would love to know more about their<br />

company and in greater detail. That’s why we have created <strong>GEA</strong> Life, the magazine for<br />

all employees of the <strong>GEA</strong> <strong>Group</strong>. <strong>GEA</strong> Life will report on our day-to-day activities. It<br />

will depict the many facets of the <strong>GEA</strong> <strong>Group</strong> in a lively fashion for the people of the<br />

<strong>GEA</strong> <strong>Group</strong> and their families. As a start, check out the articles on the <strong>GEA</strong> Allstars<br />

Band (SEE pagE 22) and our new online application management system (SEE p. 21).<br />

I hope that this medium will help to open the lines of communication and to enable<br />

you to learn more about each other. Our employees can be proud of their work and<br />

their achievements, which sometimes are simply spectacular. Let’s share these great<br />

contributions to our joint success with others at <strong>GEA</strong> <strong>Group</strong>. <strong>GEA</strong> Life will spread<br />

the word among your colleagues in five languages. Finally, I hope the magazine will<br />

encourage you to follow the motto ‘Share with pride, copy with pride’ (within the<br />

corporation) and swap good ideas if they help to do a job better. Of course, we cannot<br />

live from copying alone. Instead, we’ve got to translate our own good ideas into<br />

action. That’s the reason for the new Ideas and Improvement Management project<br />

known as I²M (SEE pp. 26-29).<br />

Before I leave you, I just want to welcome my colleague Niels Graugaard. He succeeds<br />

Peter Schenk and has been a member of the Executive Board of the <strong>GEA</strong> <strong>Group</strong> since<br />

August 1, 2007.<br />

Go ahead and enjoy <strong>GEA</strong> Life.<br />

Yours Jürg Oleas<br />

Chairman of the Executive Board<br />

<strong>GEA</strong> <strong>Group</strong> Aktiengesellschaft<br />

EdiTOriAl | 1

2 | CompAny CompAny |<br />

WHo WE ArE – THE<br />

COrPOrATE STOry<br />

Following extensive restructuring, beginning in 2003, our company has concentrated on process<br />

engineering and equipment. the disposition of our plant engineering segment had two effects:<br />

on the one hand our company got a completely different face, on the other hand we suddenly<br />

were less interesting for the media, as plant engineering attracted a lot of media attention. that<br />

is why we had to develop a new identity and strategy for the gea group. the result is the Corporate<br />

story. it describes who we are, why we are organized the way we are and what’s so special<br />

about the gea group.<br />

These are the questions we have to<br />

answer for our target groups – the capital<br />

market, employees, customers, suppliers,<br />

the general public – on a daily<br />

basis. People want to know what the<br />

unifying thread is that runs through all<br />

of the <strong>GEA</strong> <strong>Group</strong>’s activities. The <strong>GEA</strong><br />

<strong>Group</strong> concentrates on two basic processes:<br />

heat exchange and separation.<br />

We are experts in basic operations and<br />

technology in both these areas. Our machines<br />

and processes warm, cool, freeze,<br />

separate, dry, measure and agglomerate<br />

a great variety of materials or combinations<br />

thereof. We offer these technologies<br />

to the food-processing, chemical/petrochemical,<br />

energy generation,<br />

HVAC, pharmaceutical and cosmetic<br />

industries, to name a few.<br />

Engineering Excellence<br />

Each of the eight divisions – Air Treatment,<br />

refrigeration, Process Equipment,<br />

Mechanical Separation, Dairy Farm Systems,<br />

Energy Technology, Process Engineering<br />

and Gas Cleaning – stand for (at<br />

least) one core technology. These technologies<br />

constistute the basic operations<br />

of process engineering and are needed<br />

in either the same or alternating combinations<br />

in a number of sectors. This is<br />

what keeps our company together. It is<br />

particularly important for us to explain<br />

this to the capital market in a way that<br />

makes this target group understand that<br />

we are no conglomerate – as these companies<br />

have to face the fact that they are<br />

discounted.<br />

The Corporate Story also marks the<br />

launching of a new claim for the <strong>GEA</strong><br />

<strong>Group</strong>: Engineering Excellence. The<br />

claim has two different meanings: When<br />

we say ‘Engineering Excellence’, we’re<br />

claiming that we are delivering top engineering<br />

performance. At the same time,<br />

we intend to redefine what ‘Excellence’<br />

means for us. Good is not good enough –<br />

we want to be extraordinarily good. We<br />

intend to render that special service that<br />

is going to distinguish us from the competition.<br />

This is part of our claim as well<br />

and thus, a core element in our Corporate<br />

Story.<br />

decentralized diversity<br />

What really makes us unique is our decentralized<br />

structure. Why is that such<br />

an advantage? Doesn’t it make things<br />

somewhat confusing? The <strong>GEA</strong> <strong>Group</strong><br />

promises its customers to create value<br />

together. In order to accomplish that we<br />

offer customers quicker, more flexible<br />

companies that are among the leaders in<br />

their field. At the same time, customers<br />

enjoy the stability of a strong technology<br />

group. If additional process solutions<br />

are necessary, they will get perfectly<br />

coordinated interfaces, in other words,<br />

‘Engineering Excellence’. Our customers<br />

pay good money for our machines and<br />

technologies; they should also be able<br />

to earn good money with them. We call<br />

that a partnership for creating value.<br />

We could not imagine the success of the<br />

<strong>GEA</strong> <strong>Group</strong> without the strong will to<br />

do our best. This is also a part of our<br />

identity. If we want people to produce<br />

excellent work and excellent decisions,<br />

we must give them the opportunity to<br />

do that. That’s what we as a company<br />

consider to be our duty.<br />

Wanted: young professionals<br />

recently, we’ve been worrying about<br />

the shortage of young professionals, especially<br />

of engineers. We are competing<br />

against large brand names. We can’t<br />

match their allure because of our size<br />

and the business that we are in. What<br />

we can offer though, is the chance<br />

even for younger employees to assume<br />

responsibility. Our relatively flat hierarchies<br />

are also attractive. It isn’t just the<br />

job that counts at the <strong>GEA</strong> <strong>Group</strong>; it’s<br />

the person. More than two thirds of our<br />

management positions are staffed with<br />

people from our own ranks. In our company<br />

everybody gets the opportunity for<br />

individual promotion and success both<br />

domestically and internationally.<br />

The story of the ‘new’ <strong>GEA</strong> <strong>Group</strong> has<br />

already been a success story. And there<br />

are many reasons arguing for further<br />

success in the future. These reasons are<br />

quintessence of our Corporate Story.<br />

“It occurred to me again<br />

during the workshop: a lot<br />

of our strength comes from<br />

being decentralized and<br />

diverse ...“<br />

Julia Ehlert, Head of internal Audit,<br />

<strong>GEA</strong> <strong>Group</strong> Aktiengesellschaft<br />

“I see the <strong>GEA</strong> <strong>Group</strong> from the perspective of the<br />

holding company. I’ve visited all the divisions and I<br />

frequently visit individual companies. That’s the way<br />

I see things. The workshop was a sort of ‘<strong>GEA</strong> in<br />

miniature’ with all the similarities and differences –<br />

thanks to the other participants who know the<br />

operative side better than I do. It was a good mixture.<br />

It occurred to me again that many of our<br />

strengths are due to the fact that we have such a<br />

decentralized organization and we are so diverse –<br />

even though it’s hard to coordinate it all, unfortunately.<br />

The Corporate Story has to sort of square the<br />

circle – strengthening our common Corporate Identity<br />

around a decentralized, diverse core.“<br />

How did participants take to the Corporate story workshop? What did they think of their input?<br />

What do they expect from the Corporate story, its implementation now? gea <strong>life</strong> spoke with<br />

two participants from the March workshop …<br />

Jörg römermann, Sales region Central<br />

Europe, WestfaliaSurge deutschland GmbH<br />

“We have some strong brands in our division – including<br />

WestfaliaSurge. The value of these brands,<br />

our thoughts and ideas need to be reflected in the<br />

Corporate Story, too. I’ve spoken out in favor of<br />

that. Otherwise, I restricted myself to listening carefully.<br />

After all, we have quite an impressive history<br />

ourselves. In fact, I would prefer to use that for our<br />

external communication. For internal communication<br />

and corporate identity though, I find the Corporate<br />

Story extremely important. I presented the<br />

results of the workshop in the division afterwards<br />

and we discussed it. That way, everyone knows<br />

how the Corporate Story is unfolding and we don’t<br />

end up confronted with a fait accompli. Brands like<br />

WestfaliaSurge deserve a place alongside the <strong>GEA</strong><br />

brand. I’m sure that ‘WestfaliaSurge – a part of the<br />

<strong>GEA</strong> <strong>Group</strong>’ would benefit from the Corporate Story<br />

and keep us clearly positioned for our customers and<br />

our employees.“

| CompAny<br />

COrPOrATE STOry WorkSHop<br />

twelve colleagues met in Dusseldorf in early March for a weekend workshop to generate the<br />

basic elements of the Corporate story. Ceo Jürg oleas and Ferdinand steves, senior Vice president<br />

personnel, handpicked the team to reflect a cross section of all hierarchies and disciplines.<br />

Workshop participants from the holding and the divisions worked out the basic elements of the<br />

Corporate story.<br />

The new Corporate Story is<br />

pitched to the information<br />

needs of the company’s stakeholders.<br />

Each target group has<br />

its own interest in the <strong>GEA</strong><br />

<strong>Group</strong>. The capital market<br />

(shareholders and analysts) is<br />

interested in management running<br />

a tight ship and achieving<br />

the highest possible return on<br />

capital employed. Employees<br />

are interested in job security.<br />

Customers, on the other hand,<br />

want to know more about<br />

product benefits and group<br />

performance.<br />

Straight from the horse’s<br />

mouth<br />

Input from the day-to-day business<br />

plus the insight of people<br />

involved in operations were<br />

necessary in order to be able<br />

to provide clear, meaningful<br />

answers to these various questions.<br />

results of group work were presented on walls.<br />

Jürg Oleas underscored the<br />

importance of a Corporate<br />

Story for the <strong>GEA</strong> <strong>Group</strong> on<br />

the opening day of the workshop<br />

as he explained the background<br />

in detail to the participants<br />

and initiated them into<br />

the project.<br />

Colleagues were in great demand as well<br />

when it came to shooting the material for<br />

the Corporate Story brochure: they are<br />

represented in the new publication as lay<br />

models now.<br />

CompAny | 5<br />

Men at Work<br />

Are the light and the angle right? How’s the<br />

framing? Uwe Jülichs, Corporate Communications<br />

<strong>GEA</strong> <strong>Group</strong>, photographer Maik<br />

Scharfscheer and Andreas Naroska, Head of<br />

Logistics with the Dairy Farm Systems division<br />

in Bönen, (l. to r.) inspect the first shots<br />

on the notebook.<br />

tHE mAkinG of …

| CompAny<br />

The Air Treatment division provides<br />

solutions for sophisticated<br />

interface functions primarily by<br />

adding specific services to its<br />

existing range. These solutions<br />

have performed outstandingly,<br />

for example in connecting<br />

air-conditioning to building<br />

management systems and remote<br />

maintenance systems.<br />

Air Treatment<br />

“<strong>GEA</strong> creates the perfect atmosphere”. This claim by the Air Treatment division<br />

is more than just a catchy slogan, as it sums up its business philosophy. The solutions<br />

devised by this division use energy-saving methods to purify air and to<br />

humidify or dehumidify it, heat or cool it and transport it to its destination. This<br />

includes heat recovery and the use of water as a coolant.<br />

<strong>GEA</strong> offers customized systems for various requirements in the workplace and<br />

home, such as air-handling units, decentralized units for business and industrial<br />

applications such as fan convectors and air treatment appliances, chillers, control<br />

systems and switch cabinets.<br />

One of the most important factors in our business relationships is to enable our<br />

clients to make the right decision. One of the ways in which we can do this is<br />

to provide them with our references. A number of hotels rely on solutions offered<br />

by <strong>GEA</strong>, such as the Adlon in Berlin, the Hyatt Regency in Mainz, the Villa<br />

Kennedy in Frankfurt am Main and the Hilton in Istanbul. This list could be<br />

continued with European references from sporting facilities, hospitals, the food<br />

industry and museums.<br />

Market focus and<br />

flexibility<br />

Flat hierarchies – swift, direct<br />

decision-making: all companies<br />

in the <strong>GEA</strong> <strong>Group</strong> translate their<br />

market focus and flexibility into<br />

high-quality service, growth and<br />

profitability.<br />

Benefiting from the clear separation between operational and strategic functions<br />

and flat decision-making hierarchies, each company in the <strong>GEA</strong> <strong>Group</strong> can act as<br />

quickly as smaller competitors in the market.<br />

The market focus and flexibility of all parts of the <strong>Group</strong> derive firstly from the<br />

decentralization of functions, which means that each operating unit has the freedom<br />

to conduct its business as it sees fit and to assume responsibility for specific<br />

markets.<br />

And secondly, they derive from the composition of the product range. Complementing<br />

the largely modular structure of its products, the <strong>GEA</strong> <strong>Group</strong> offers a<br />

wide product range within its core competency. This enables it to customize its<br />

components, systems and processes for a large number of clients and sectors. Its<br />

divisions work together on projects, thereby reaping synergies.<br />

Each <strong>GEA</strong> company constitutes the best specialist for its clientele. At the same<br />

time, customers can rest assured that the <strong>GEA</strong> <strong>Group</strong> understands their overall<br />

processes and, consequently, their critical interfaces by virtue of its combined<br />

expertise.<br />

28 29<br />

Refrigeration<br />

focused, agile, investor-friendly<br />

After extensive restructuring, the <strong>GEA</strong> <strong>Group</strong> has a new face now.<br />

From now on, the <strong>Group</strong> will focus on the two basic technical processes,<br />

heat exchange and separation. The <strong>GEA</strong> <strong>Group</strong>’s holding<br />

company is listed on the stock exchange. Its job is to lead the company<br />

with a view towards growing corporate value.<br />

market focus and flexibility<br />

Customers can rely on the best specialists when dealing with “their“<br />

<strong>GEA</strong> company. At the same time, they have the assurance that the<br />

<strong>GEA</strong> <strong>Group</strong>’s knowledge pool means understanding of the whole<br />

process and its critical interfaces.<br />

42 43<br />

People are our most<br />

valuable asset<br />

The division‘s cooling and<br />

refrigeration systems use natural,<br />

environmentally friendly<br />

substances – primarily ammonia<br />

and carbon dioxide. The high<br />

efficiency and lower cost of<br />

buying and disposing of these refrigerants<br />

make them financially<br />

attractive as well.<br />

The Refrigeration division is active in the field of industrial cooling of processes<br />

and products. The product range is based on two core components – reciprocating<br />

compressors and screw compressors - which, together with other refrigeration-cycle<br />

components and devices, form part of complete refrigeration plants<br />

and complex systems.<br />

The fields in which these are principally used are the quality-assured processing,<br />

storage and transportation of foodstuffs. There are also numerous applications,<br />

for example in the chemical and pharmaceutical industries, as well as in the field<br />

of ship refrigeration. Other applications for our refrigeration technology include<br />

ice factories and increasingly sophisticated leisure facilities such as indoor skiing.<br />

The division‘s preventive plant monitoring systems, maintenance procedures<br />

and spare-parts logistics are among the world‘s best in this sector.<br />

The wide range of areas in which<br />

our employees work, the global<br />

nature of the <strong>GEA</strong> <strong>Group</strong>‘s<br />

operations and its deliberate encouragement<br />

of an entrepreneurial<br />

spirit and behavior ensure that<br />

our employees acquire extensive<br />

skill sets. They are flexible,<br />

results-driven and devise lasting<br />

process engineering solutions.<br />

The <strong>GEA</strong> <strong>Group</strong>‘s success is driven by its highly qualified employees, who have<br />

been educated and trained to the highest standards and work in positions that<br />

are consistent with their abilities and objectives.<br />

Underpinned by binding management principles, transparent rules and cutting-edge<br />

HR tools, the <strong>GEA</strong> <strong>Group</strong> encourages and demands excellence from<br />

its workforce in terms of their performance and results. To achieve these goals,<br />

it stresses the importance of quality by promoting fairness, decentralization, an<br />

entrepreneurial approach and personal responsibility in an environment that is<br />

conducive to competition.<br />

All members of staff receive regular training to ensure that they possess the necessary<br />

technical, commercial and organizational expertise for their work that<br />

customers and investors can expect of a leading process engineering firm.<br />

The <strong>GEA</strong> <strong>Group</strong>‘s employees are able to apply the methods most appropriate<br />

to any given situation and to implement the optimum solutions in their field of<br />

activity. What particularly distinguishes them is their willingness and ability to<br />

create synergies, thereby enhancing the company‘s performance, by optimizing<br />

the development, production and distribution functions and collaborating seamlessly<br />

across disciplines.<br />

20-POINT COrPOrATE<br />

idEntity PrOGrAM<br />

the Corporate story is going to be published in form of a brochure. you will find 20 aspects under<br />

the title ‘perspectives’ – 20 good reasons for the gea group.<br />

What drives us<br />

In its new form, our company serves industries that are less cyclical.<br />

Fundamentals are driving the company such as the continual<br />

growth in world population.<br />

Creating value<br />

By continually refining procedures and materials, we are creating<br />

value. This value helps users avoid cost traps. At the same time, we<br />

help customers boost their earning power. The <strong>GEA</strong> <strong>Group</strong> considers<br />

itself a partner in the value-creation process.<br />

Generating growth by meeting differing needs<br />

The highly industrialized markets of the <strong>GEA</strong> <strong>Group</strong> are characterized<br />

by a growing need for high-quality products as well<br />

as changes in taste and style. On the other hand, growing<br />

markets such as Brazil, russia, India and China are more basic<br />

but they present the opportunity of selling extraordinarily high<br />

quantities.<br />

organic growth<br />

The <strong>GEA</strong> <strong>Group</strong> realizes its potential for profitable growth primarily<br />

on its own. The product lineup in processing technology is wide,<br />

the concern is balanced locally while being present throughout the<br />

globe in dynamic growth markets.<br />

Growth – enhancing acquisitions require careful<br />

planning<br />

We have to acquire other businesses in order to meet the expectations<br />

of the capital market. That means that newly acquired businesses<br />

have to start contributing to the success of the <strong>GEA</strong> <strong>Group</strong><br />

immediately. We’ve proven that we can successfully integrate companies<br />

that we acquire. It isn’t just because we have strong brands<br />

at our disposal. We’ve reached this high degree of acceptance<br />

through our decentralized management style.<br />

organization follows function – the structure of<br />

the <strong>GEA</strong> <strong>Group</strong><br />

Divisions are structured according to their core technologies.These<br />

technologies form the basis of process engineering and they are<br />

needed in numerous industries in the same or other combinations.<br />

our goal: being not just good but exceptional<br />

Entrepreneurs drive growth at the <strong>GEA</strong> <strong>Group</strong>. They want to take<br />

charge of their work and they want to see satisfied customers.<br />

Creating sustainable value for our stakeholders isn’t just a matter<br />

of size; it also has to do with striving for extraordinary results.<br />

our strategic guiding principles<br />

Market leadership and focus. Technical leadership through innovation.<br />

Focused on results. Calculated risk-taking.<br />

Adding value for our customers –<br />

the <strong>GEA</strong> <strong>Group</strong>’s value proposition<br />

Our promise extends to all aspects of value creation. The <strong>GEA</strong><br />

<strong>Group</strong> offers fast, flexible companies that are among the leaders in<br />

their field. At the same time, customers enjoy the security and the<br />

stability afforded by a strong technology company.<br />

operational excellence<br />

Our activities aim to increase corporate value. The focus here is on<br />

boosting profitability. This is a bellwether for the operative excellence<br />

of the companies within the <strong>GEA</strong> <strong>Group</strong>.<br />

Creating value, active and available worldwide:<br />

the <strong>GEA</strong> <strong>Group</strong>’s services<br />

Maximizing the usability of an investment throughout the entire<br />

<strong>life</strong>cycle of process technology demands clearly budgetable service<br />

modules and preventative maintenance. Proactive services like<br />

these prevent problems before they actually occur.<br />

CompAny | 7<br />

people are our most valuable asset<br />

Highly trained, highly qualified people working in positions that<br />

suit their ability and their goals are the main reason for the <strong>GEA</strong><br />

<strong>Group</strong>’s success. Supported by binding management guidelines,<br />

understandable rules and modern personnel tools, the <strong>GEA</strong> <strong>Group</strong><br />

promotes and encourages excellence.<br />

Achievement needs to be nurtured<br />

We fill more than two thirds of our management positions with<br />

people from our own ranks. We provide opportunities for every<br />

employee to get ahead and succeed in domestic and international<br />

markets.<br />

Sharing knowledge for the common good<br />

The <strong>GEA</strong> <strong>Group</strong> combines the knowledge of more than 250 highly<br />

specialized companies. Knowledge management makes ideas, insights,<br />

methods and experience – the DNA of leading technology<br />

specialists, as it were – available for joint projects.<br />

innovation and improvement are key to<br />

everything we do<br />

Translating developments quickly and economically into marketready<br />

products and methods is a major success factor both for the<br />

<strong>GEA</strong> <strong>Group</strong>’s leading position and its future growth.<br />

Sophisticated, accurate and transparent:<br />

the <strong>GEA</strong> <strong>Group</strong>’s risk management<br />

Today, the <strong>GEA</strong> <strong>Group</strong> is well protected against negative influences<br />

both internally and externally. Low levels of complexity, fewer oneoff<br />

orders, consistent job selection and shorter project durations<br />

make risk in the machine tool business well manageable.<br />

the <strong>GEA</strong> <strong>Group</strong> as a corporate citizen<br />

The <strong>GEA</strong> <strong>Group</strong> treats the cultures, norms and laws of different<br />

countries or regions with respect. It is our responsibility towards our<br />

stakeholders and to society at large.<br />

Sustainability<br />

The sustainability of its solutions fortifies the <strong>GEA</strong> <strong>Group</strong>’s market<br />

position and paves the way for profitable growth. Our machines<br />

and processes result in high-quality products that have long lowered<br />

operating costs and conserved resources.

| CompAny<br />

WE’rE GETTING bEttEr All tHE timE!<br />

KAIzEN PrOMOTES VALUE CrEATION.<br />

it all began with the realization that keeping customers is less costly than acquiring new ones.<br />

What can be more appealing to customers than constant, tangible improvement? that’s exactly<br />

what we’re trying to achieve with the aid of our internal advisors gea Consulting gmbH<br />

(see bOx) and the kaizen management system.<br />

The word ‘Kaizen’ in Japanese means improvement. Not all<br />

at once, but step by step, as Asian philosophy teaches us. It<br />

doesn’t mean that everything has to be new and different. We<br />

just want to improve in places where the opportunity presents<br />

itself.<br />

Whatever increases value<br />

It’s a matter of separating the wheat from the chaff. Keep<br />

any activity that increases the value of a product or service,<br />

eliminate those activities that consume resources without adding<br />

any value. The quality of products or services will improve,<br />

services will become prompter and more flexible and costs will<br />

drop. Every process will undergo scrutiny and will be improved<br />

with regard to customer needs.<br />

toyota – a shining example of kaizen<br />

Kaizen is not the latest rage among consulting companies:<br />

Toyota came up with the concept in the 1950s. The Japanese<br />

automobile manufacturer was in a crisis then. However, instead<br />

of shedding 0 per cent of its staff, the company opted<br />

for permanent quality enhancement. They collected methodologies<br />

from the US and Europe, combining them into what<br />

became known as the Toyota Production System. It seems to<br />

have paid off because Toyota passed General Motors in early<br />

2007 becoming the largest automobile manufacturer in the<br />

world.<br />

Extending kaizen to production and administration<br />

We’re not in a crisis but nevertheless we want to provide our<br />

customers with lots of reasons to continue doing business with<br />

us - whether it’s in manufacturing or in administration. While<br />

manufacturing costs continue to drop, administration costs<br />

have risen briskly. Today nearly everyone complains about a<br />

drastic rise in the flood of information. More than an hour<br />

each day is lost just handling email and even more time is<br />

consumed in unfocused meetings. Finally, very few employees<br />

have an eye on the entire process, which means that they do<br />

not realize that their colleagues are their prime customers.<br />

kaizen at <strong>GEA</strong><br />

I²M, on the one hand, solicits individual suggestions for<br />

improvement. Kaizen, on the other hand, aims at systematic<br />

improvement by teams of employees. Workshops in manufacturing<br />

and administration, training sessions, analyses of<br />

potential, plus company visits are all ways to come up with<br />

suggestions for improvement, to verify their feasibility and<br />

then implement them. The result will be a world-class standard<br />

in manufacturing and administration, the best prerequisites for<br />

loyal customers.<br />

gea Consulting gMbH<br />

Guido Beyß and Marco Silz head <strong>GEA</strong> Consulting GmbH. Fifteen<br />

experienced consultants provide support to all <strong>GEA</strong> divisions<br />

and companies across a variety of projects. Services include<br />

strategy, support during acquisition projects, help with investment<br />

considerations including execution and risk management,<br />

as well as zero-based budgeting, corporate restructuring and<br />

process optimization by Kaizen. The emphasis initially is on creating<br />

transparency. <strong>GEA</strong> Consulting GmbH then works with<br />

people to develop concepts, implementing them on site in the<br />

operative units. It combines expertise in process optimization<br />

with know-how specific to <strong>GEA</strong>. As a central internal service,<br />

affiliated to the ressort process technology of the <strong>GEA</strong> Board,<br />

<strong>GEA</strong> Consulting combines expertise in process optimization<br />

with <strong>GEA</strong> specific know-how.<br />

kAi<br />

CHAnGE<br />

ZEn<br />

Good<br />

(for the better)<br />

Kaizen is a composit of the Japanese words ‘kai’ and ‘zen’.<br />

CompAny | 9

10 | CompAny<br />

BUENA viStA<br />

Microsoft Vista and the new office package may have just made their<br />

appearance on the market but we already have them. it’s not because it’s<br />

bigger or brighter or because it’s less static. instead, it’s because it’s the<br />

best solution. Management has already given its blessing to the gea corporate<br />

client, having signed a contract with Microsoft in May. the only<br />

thing that remains to be done now is the implementation.<br />

The VISTA conversion will begin in August<br />

2007 in Germany, Denmark and the Benelux<br />

countries. By February 200 , 125 different<br />

offices will have exchanged some , 00 laptops<br />

and desktops for new computers and<br />

software. Implementation for the rest of the<br />

world will proceed, country by country, beginning<br />

in January 200 . The goal is having every<br />

user at the company’s 0 different locations<br />

working with the new system by fall 200 .<br />

This radical conversion will bring some definite<br />

advantages – a high degree of standardization,<br />

global contracts with Microsoft and Dell, a<br />

single infrastructure for everyone and efficient<br />

support.<br />

Standardization: key to cutting costs<br />

Standardization is the key to getting a handle<br />

on IT costs in the eyes of leading consulting<br />

companies. It will allow us to flex our<br />

purchasing muscle, have lower maintenance<br />

and support costs. Furthermore, we will be<br />

able to link in new users easily. In line with this<br />

view, the <strong>GEA</strong> corporate client will include key<br />

applications with optimum equipment, a limited<br />

selection of laptops and desktops, a central<br />

library of applications and programs, and<br />

central maintenance.<br />

Global contracts – best conditions<br />

We have signed global contracts with providers<br />

for all the hard- and software. Not only<br />

did that allow us to cut the actual purchase<br />

price up to 50 per cent in some cases; we also<br />

have a chance to keep the number of different<br />

hard- and software elements used for the<br />

same purpose as low as possible, thus greatly<br />

reducing the coordination and maintenance<br />

effort.<br />

AN OVErVIEW<br />

OF NEW<br />

HArD- AND<br />

SOFTWArE<br />

Hardware:<br />

• Dell optipleX 755<br />

(Desktop)<br />

• Dell latituDe D430/<br />

D630/D830 (laptop)<br />

• Dell precision t3400<br />

(Workstation)<br />

Software:<br />

the preinstalled package<br />

includes:<br />

• Vista enterprise<br />

• office professional<br />

plus 2007<br />

• selected auxiliary<br />

programs like zip,<br />

acrobat reader or the<br />

at&t network client<br />

for laptops<br />

• gea it.net active<br />

Directory<br />

• Microsoft sMs<br />

Seamless connections – free<br />

flow of information<br />

Anybody registered on the <strong>GEA</strong> network<br />

will have full access to the worldwide<br />

address book and to his own data from<br />

anywhere in the world. We will all have<br />

to adhere to clear guidelines so that we<br />

can maintain this standard and the freedom<br />

that comes with it. Otherwise, its<br />

open borders could quickly degenerate<br />

into a Trojan horse, an easy target for<br />

viruses and chaos occasioned by individual<br />

expansions.<br />

Applications – everything the<br />

user’s heart desires<br />

Many jobs require special applications –<br />

these will be available, of course.<br />

However, there will mostly be only<br />

one application per job in order to cut<br />

licensing costs and reduce support<br />

needs.<br />

Efficient support – round<br />

the clock, day after day<br />

The new hard- and software is there<br />

to help you do your work. We will do everything in our power<br />

to make sure that your PCs and programs always work, that<br />

they are always updated and always protected. Before calling<br />

the hotline though, please ask a trained coworker first.<br />

CompAny | 11<br />

What will it cost?<br />

It may seem expensive at first glance, but closer examination<br />

reveals a different picture. One third of the purchase price consists<br />

of the usual expenses for replacement<br />

and leasing. We were able to negotiate<br />

another third and we will finance the<br />

final third by selling old equipment,<br />

improving processes, saving the usual<br />

expense of updates plus the new format.<br />

Bottom line: this is an unbeatable<br />

monthly fee that remains the same for<br />

every workstation.<br />

Help us ConVert!<br />

everyone will make the transition<br />

in (nearly) one fell swoop. We need<br />

your help to make this vision a reality.<br />

until the conversion, we kindly ask<br />

you to:<br />

1. refrain from purchasing licenses for Vista, office<br />

2007, Cal for Windows, exchange, sMs and sharepoint<br />

portal. licenses have already been purchased<br />

for the entire group.<br />

2. purchase and install only Vista-compatible products –<br />

if necessary.<br />

3. purchase as few new computers as possible. if a new<br />

purchase is unavoidable, buy only Dell hardware after<br />

obtaining approval from the Cio division.

12 | mArkEtS<br />

THE Colossi OF st. nazaire<br />

Gea delivers GiGantiC air Coolers and Condensers for Gas-to-liquid plants.<br />

the challenge is as huge as it is innovative: employees of the gea subsidiary batignolles<br />

technologies thermiques (btt) are currently working on a massive project in the harbor<br />

of st. nazaire (France). this entails the pre-assembly of an air-cooled condenser for a<br />

gas-to-liquid plant (in short: gtl). each of the three modules is 75 meters high,<br />

50 meters long and 15 meters wide. adding up to a total weight of 500 tons per module.<br />

Why pre-mount such colossal modules, instead of fitting the<br />

individual components together on site? Indeed, that was<br />

the original plan. But serious problems in respect of logistics,<br />

security and qualified personnel on site soon materialized.<br />

For this reason, Btt suggested shifting the pre-assembly work<br />

to France, leaving only the final assembly to be completed<br />

in Nigeria. The client agreed to this proposal. And so the<br />

Btt specialists began working in September 200 . In the<br />

interim, important elements have been fitted and an initial<br />

function test has been successfully completed. The further<br />

the work progresses, the more impressive the sheer dimensions<br />

of the task appear to be. And the clearer it becomes<br />

that the shipping of the three modules, which is planned for<br />

the spring of 200 , is likely to remain extremely exciting –<br />

despite the fact that the construction has been specially designed<br />

to be shipped.<br />

Gtl technology increasingly attractive<br />

When subjected to high pressure and high temperatures,<br />

natural gas can be used to produce diesel fuel. The resulting<br />

fuels offer greater performance while at the same time emitting<br />

fewer pollutants – in view of the urgent need to protect<br />

the environment as well as rising oil prices, this added effectiveness<br />

has generated tremendous interest. The efficiency<br />

of the process, at any rate, is beyond doubt: the GTL technology<br />

is cost-effective even at an oil price of USD 0.00 per<br />

barrel.<br />

plant productivity has been sharply<br />

increased<br />

The first GTL plants were established in the<br />

nineties. The Oryx GTL plant as well as another<br />

plant which is currently being built has a capacity<br />

of ,000 barrels per day. The Shell<br />

Pearl plant, currently under construction in<br />

Qatar, will even boast a capacity of 1 0,000<br />

barrels per day. In view of the growing demand<br />

for energy, the outlook for GTL technology<br />

is extremely positive.<br />

<strong>GEA</strong> is superbly well-positioned<br />

Indeed, this also applies to the division<br />

<strong>GEA</strong> Energy Technology. With<br />

its coolers and condensers, it is represented<br />

in all important GTL plants<br />

around the world. Consequently it is<br />

able to draw upon tremendous experience<br />

and an impressive track record –<br />

an excellent starting position for future<br />

orders.<br />

mArkEtS | 1

1 | mArkEtS mArkEtS | 15<br />

COMMON Ground<br />

The smoking area: Clairifair, keeps the peace<br />

between smokers and non-smokers.<br />

A team player<br />

Clarifair is easy to use. The system can be installed in<br />

new or existing buildings and can be integrated into<br />

existing air conditioning systems. It can even cut the<br />

costs of air conditioning through its lower air exchange<br />

rates. What’s more, Clarifair is available in various performance<br />

ratings both as a floor or ceiling-mounted<br />

model.<br />

it’s in the name: Clarifair is a combination<br />

of ‘clarify’ and ‘air’. and of course the word<br />

‘fair’ is in there as well. after all, Clarifair<br />

assures fair play for both smokers and<br />

non-smokers.<br />

For a long time, it looked as if smokers and non-smokers were<br />

not going to be able to reconcile. Strict separation and tougher<br />

laws seemed to be the only way out. Non-smokers felt put upon<br />

while smokers felt like they were being discriminated against.<br />

Now it appears that both parties will be able to settle<br />

‘out of court’. The solution: the Clarifair ventilation<br />

and filter system by <strong>GEA</strong> Air Treatment. It absorbs<br />

and eliminates nearly one hundred per cent of the<br />

smoke of up to twelve people.<br />

Clarifair battles smoke wherever it occurs – at a counter,<br />

a table or in a break room. Clarifair inhales up to<br />

1,500 cubic meters of air per hour through its large<br />

intake ducts and conducts the air through a threefilter<br />

system. The pre-filter traps large particles; the<br />

electric filter makes short work of microscopic smoke<br />

particles while the active charcoal filter removes the<br />

odor. What emerges is pure air, as the German Technical<br />

Inspection Authority (TÜV) confirms. And all of<br />

this is barely audible, thanks to a sound baffle.<br />

So smokers and non-smokers can fraternize after all, as in<br />

Austria’s tallest building, the Millennium Tower, where smoking<br />

is strictly forbidden. The only exception: the Clarifair smoking<br />

area in the foyer. Such exceptions could also become possible in<br />

other countries pending certification.<br />

electrostatic<br />

filter<br />

activated carbon<br />

filter<br />

sound absorber<br />

ionizer<br />

prefilter<br />

fan<br />

GrAfik-vErfAHrEnS-ExponAt-AutomAtionS-WAnd!<br />

CHEErS Cheers<br />

the 2007 brau beviale in nuremberg again promises<br />

to be the top international trade show<br />

for breweries and the beverage industry. participating<br />

gea companies have come up with something<br />

new and unusual for their 500 squaremeter<br />

exhibit – a ‘vision wall’ that shows what<br />

gea can do for its customers.<br />

The ‘Grafik-Verfahrens-Exponat-Automations-Wand’<br />

as the ‘vision wall’ is<br />

called in German, could<br />

win the ‘European Beer<br />

Star’ based on its name<br />

alone. Unfortunately however,<br />

the award is reserved<br />

for the beer that the ,000<br />

odd visitors at the Brau Beviale<br />

from November 1 – 1 choose<br />

as Europe’s best.<br />

<strong>GEA</strong> times eight<br />

Focal point of the stand is the ‘vision<br />

wall’ where <strong>GEA</strong> companies Huppmann,<br />

Tuchenhagen Brewery Systems, TDS Tuchenhagen<br />

Dairy Systems, Tuchenhagen, Westfalia<br />

Separator, <strong>GEA</strong> Ecoflex, <strong>GEA</strong> Diessel and Procomac<br />

will demonstrate where their products, technology<br />

and software fit in from brew house all the way to filling plant.<br />

the new <strong>GEA</strong> <strong>Group</strong> Stand: expertise from A to Z<br />

This year our stand is completely different from the one we had last<br />

year. The companies participating, the size and the concept vary<br />

from year to year, but this year is something else. A lot has changed,<br />

beginning with our new location in Hall 7, first-time exhibitors<br />

Huppmann and Procomac, our new exhibit strategy and our tradeshow<br />

concept. The <strong>GEA</strong> <strong>Group</strong> will now be able to demonstrate<br />

its expertise in the brewery and beverage industry from A to z. To<br />

remind our customers of this expertise, all they will have to do is<br />

take a glance at the new ‘Grafik-Verfahrens-Exponat-Automations-<br />

Wand.’ Cheers!

1 | mArkEtS mArkEtS | 17<br />

A fACtory OF SupErlAtivES<br />

<strong>GEA</strong> PHE Systems builds the world’s most modern<br />

factory for plate heat exchangers, for the world’s<br />

largest market, in record time.<br />

the american market is the largest in the world for heat exchangers. if a company wants to do business<br />

in america, it’s got to be there. gea pHe systems, responsible for this business within the gea process<br />

equipment Division, took the challenge. it built the world’s most modern factory in york, pennsylvania,<br />

within a very short time and, in doing so, it pulled away from the competition.<br />

america is the largest market in the<br />

world for heat exchangers. For a<br />

company to do business in america,<br />

it’s got to be there. gea pHe systems,<br />

responsible for this business within<br />

the gea process equipment Division,<br />

accepted the challenge: it built the<br />

world’s most modern heat exchanger<br />

factory in york, pennsylvania, and in<br />

doing so, pulled away from the competition.<br />

What’s more, the whole project<br />

was completed in record time.<br />

gea pHe systems’ new factory is more<br />

than just a symbol of its global position.<br />

it’s a 60-million dollar investment<br />

that makes it the leading center of<br />

competence for plate heat exchangers<br />

in north america.<br />

the first phase of the construction, an<br />

ultra-modern plant for brazed ‘gb’<br />

heat exchangers, was completed in<br />

record time – just some few months<br />

from foundations to start-up. phase<br />

two, to manufacture gasketed heat<br />

exchangers, is expected to be completed<br />

by the end of the year. the<br />

new factory will allow gea pHe<br />

systems north america to provide a<br />

complete range of heat exchangers,<br />

for nearly any industrial application,<br />

throughout north america, with the<br />

efficiency and economy its customers<br />

expect.<br />

the factory will provide 260 new jobs<br />

for the highly qualified workforce<br />

available in the local area. kirby lindtveit,<br />

senior Vice president sales at<br />

<strong>GEA</strong> PHE SySTEMS<br />

Within the gea process equipment<br />

Division of the international gea<br />

group aktiengesellschaft, gea pHe<br />

systems is responsible for plate heat<br />

exchanger technology. With around<br />

750 employees gea pHe systems<br />

achieves an annual group turnover<br />

with plate heat exchangers of several<br />

hundred million euros.<br />

gea pHe systems na, stresses: “york<br />

is the center of the air-conditioning<br />

business in the united states. it has a<br />

good supply of extremely well educated<br />

engineers and workers. With<br />

american and german engineers<br />

working together in this modern<br />

plant we will be able to manufacture<br />

state-of-the-art products and consolidate<br />

our leading position in the<br />

marketplace.“<br />

gea pHe systems is fast becoming a<br />

global player: even though the york<br />

plant represents a huge investment<br />

it’s just another step on the way. in<br />

2003 a heat exchanger plant was<br />

opened at the companies headquarters<br />

in sarstedt, germany; two years<br />

later, a large press in ystad, sweden,<br />

came on line; and earlier this year,<br />

gea ecoflex/india opened a modern<br />

factory for small and medium-sized<br />

heat exchangers in pune, india, to<br />

serve the asian-pacific markets.<br />

Ribbon-cutting in York

1 | mArkEtS<br />

minErAl oil SEpArAtor<br />

turnS 100<br />

100 years of service to our Customers – 100 years of success: it all began with a separator<br />

for the dairy industry developed by ramesohl & schmidt, the company from which<br />

Westfalia separator evolved. today, we’re the market leader in centrifugal separation of<br />

mineral oil and its byproducts. it’s all because we listened to our customers.<br />

from milk to mineral oil<br />

All sorts of filtering devices had been used to purify used lubricants,<br />

all more or less successful. However, the filters failed completely<br />

when it came to steam cylinders because the lubricants<br />

used there also contained water. It was only natural then that<br />

ramesohl & Schmidt should apply the same centrifuge technology<br />

that they had applied to milk to solve the problem of steam<br />

cylinder lubricants. The result was the first mineral oil separator,<br />

which bore the proud name “Molekül”, in 1907.<br />

Customer benefit<br />

Paying attention to the needs of our customers has not only improved<br />

the performance, efficiency and value of our centrifuges;<br />

it has also allowed us to identify new applications. Today, our<br />

separators and decanters play a major role in more than 2,500<br />

processes worldwide. They are used to process fuel oils for marine<br />

and offshore diesel engines. They also desalinate and wash gasturbine<br />

oils, they purify lubricants in power plants and they degrease<br />

and clean emulsions, cooling lubricants and hydraulic oils.<br />

“Molekül”, the first mineral oil separator, had an output of up to 100 liters per hour.<br />

Modern systems can clean up to 7,000 liters per hour.<br />

our customers are our future<br />

Today, performance isn’t the only thing; environmental criteria<br />

count as well. The key here is a holistic approach to progress.<br />

One example is our SeaProtect Solutions from 2005.<br />

Our BilgeMaster, SludgeMaster and CombiMaster protect the<br />

ocean’s delicate ecosystem and make sure that the norms<br />

for purity, such as for bilgewater, stay at 5 ppm (parts per<br />

million).<br />

‘Always at your side’ is not just our promise to customers; it’s<br />

our promise to future generations.<br />

our bilgeMaster purifies bilgewater to the tune of<br />

5 parts per million. the water can be pumped back<br />

into the sea as it is no pollution hazard any longer.<br />

Centrifugal oil conditioning system<br />

mArkEtS | 19

20 | EmployEES<br />

rEADy FOr tAkE-off?<br />

the fly AG leadership simulation is a lot more than just a model airplane.<br />

During the three-day leadership roleplay, participants just<br />

might be tempted to recall their childhood: they get to build<br />

model airplanes. Organizing the activity though can pose a<br />

serious challenge. Participants have to create a company with<br />

three levels of hierarchy – management, foremen and workers.<br />

Some of these have added responsibilities such as the works<br />

council, warehousing or security. Just one day into the exercise,<br />

the boundaries begin to blur between a real company and the<br />

Fly AG. “Fly AG is an extremely realistic slice of <strong>life</strong>“, acknowledges<br />

Stefan Cüppers, Head of Accounting and Controlling<br />

at <strong>GEA</strong> subsidiary 2H Kunststoff GmbH. Kits may have missing<br />

parts and so, it’s time to improvise quickly. Then a customer<br />

complains about project delays – and that is just the beginning.<br />

unanimous Agreement<br />

Fly AG has soared since its introduction. Biesen offers the seminar<br />

not only to the <strong>GEA</strong> <strong>Group</strong> but also to clients in the chemical,<br />

steel and insurance industries. <strong>GEA</strong> is special nevertheless.<br />

“We are going to conduct Fly AG for the first time in English<br />

here”, says Biesen, something that is indispensable for <strong>GEA</strong>,<br />

given its international involvement.<br />

Biesen has never received any negative feedback. On the contrary:<br />

“Fly AG was one of the best seminars I have ever participated in.<br />

It was very hard but I learned a lot about how communication<br />

works in groups and hierarchies”, recalls Julia Ehlert, Head of<br />

Internal Audit of the <strong>GEA</strong> <strong>Group</strong>. One situation in particular will<br />

remain in her memory for a long time. She played the boss and<br />

she thought that she had made the best decision possible for<br />

all involved. Unexpectedly though, her decision was met with<br />

criticism. “The decision was okay but I didn’t involve the others –<br />

the ones who were affected – in the decision-making process”,<br />

says Ehlert.<br />

rotating jobs<br />

Participants draw lots for jobs and go back and forth between<br />

being leaders and subordinates. Their old skills are useless in<br />

each new situation, so they are embarking on new territory<br />

good ideas come to some people in the shower; others have<br />

their moments of brilliance just before dropping off to sleep.<br />

a somewhat unusual idea occurred to job trainer ralf biesen<br />

while building a model glider. twelve years ago, he was searching<br />

for a training concept that could convey the idea of<br />

leadership in a concrete, and not just theoretical way. biesen<br />

thought that he was on to something. so did the gea group,<br />

which incorporated the seminar into its training program.<br />

each and every time. They get to experience all the highs and<br />

lows of a business ranging from ‘mission accomplished’ to impending<br />

bankruptcy. “Not even I know how Fly AG will fare at<br />

the beginning of a seminar. But I do have more than 00 ways<br />

of intervening”, explains Biesen. Participants get to test their<br />

limits. “The results can often be surprising”, says Biesen, but<br />

that’s necessary in order for lessons like leadership style, communication<br />

and organization to take hold.”<br />

the difference between acting and experiencing<br />

Volker Andußies, Head of Management Development, explains:<br />

“This seminar is basically suitable for anyone in management –<br />

all the way to the top. It underscores patterns of behavior and<br />

shows how to optimize them. Mostly though, we use it in our<br />

basic training ’Leadership and Management’ for our management<br />

trainees. We want them to be familiar with the various<br />

demands of leadership. They should get to know the difference<br />

between the signals that management is sending and what the<br />

staff actually receives because this is where we have the most<br />

acute problems.”<br />

seMinar goals<br />

• experience leadership from<br />

different perspectives<br />

• determine what the factors<br />

of successful leadership are<br />

• get direct feedback on the<br />

impact of one’s own leadership behavior<br />

• define positive leadership characteristics<br />

• transfer lessons learned to the workplace<br />

interested?<br />

please contact your Human resources Department.<br />

<strong>GEA</strong> IS JUST A<br />

CliCk<br />

AWAy<br />

i-Grasp by Stepstone is the<br />

<strong>GEA</strong> <strong>Group</strong>’s online job<br />

application system.<br />

When it comes to job applications, bond paper, an attractive folder and meticulous handwriting<br />

will soon be things of the past. More and more people are applying via the internet. now they<br />

can also apply to the gea group online.<br />

During the third quarter of 200 approx.:<br />

. million Germans visited a<br />

job Web site at least once a month –<br />

and the trend is growing. The Internet<br />

has become the primary medium<br />

for job applications. It’s also the best<br />

way to reach graduates with one to<br />

three years of work experience, a key<br />

target group for <strong>GEA</strong>. The <strong>GEA</strong> <strong>Group</strong><br />

has been using the i-Grasp application<br />

management system by Stepstone<br />

since late April/early May 2007 for jobs<br />

in Germany. European-wide implementation<br />

is envisaged for 200 .<br />

targeted search, quick work<br />

i-Grasp supports every recruiting process<br />

from ad design through handling<br />

the applications themselves to tracking<br />

statistics for the Human Capital<br />

Cockpit, the company-wide personnel<br />

tracking system. “i-Grasp makes searching<br />

for suitable staff quicker and<br />

easier”, says Michael Kämpfert, Head<br />

of Human resources (Hr) for the <strong>GEA</strong><br />

<strong>Group</strong>. Melanie Hartleif of the Human<br />

resources Departement seconds that.<br />

She does anticipate some extra work<br />

though. “People in Hr will have to<br />

actively search out applicants. We’ll<br />

constantly have to rethink things.”<br />

Petra richert, of the Human resources<br />

Department at Westfalia Separator<br />

AG, is certain that the investment<br />

will be worthwhile. “It will take some<br />

time to tailor the system to the <strong>GEA</strong><br />

<strong>Group</strong>. We’re continually discovering<br />

new ways to improve it.” richert has<br />

already handled one successful online<br />

application. “It was fun working with<br />

i-Grasp. We moved a lot quicker“.<br />

flexible and convenient<br />

you’ll find i-Grasp not only on the <strong>GEA</strong><br />

<strong>Group</strong>’s Web site. Every division can<br />

place it on its Web site and its Intranet,<br />

thus permitting external applicants<br />

to apply either to the central Human<br />

resources Department or via the divisions.<br />

Someone who is looking to<br />

change positions internally can check<br />

out job offerings on the Intranet. Of<br />

course, it is also possible to take the<br />

initiative (for internships, too) and<br />

receive job offers in line with a previously<br />

created applicant profile. A filter<br />

even allows employees to restrict the<br />

search to individual divisions and re-<br />

EmployEES | 21<br />

gions. Applicant Hüseyin Eryilmaz cites<br />

the system’s convenience and clarity.<br />

“<strong>GEA</strong>’s online application-management<br />

system is very structured and easy.<br />

I was able to target my search, and I<br />

also receive emails notifying me of job<br />

openings.“<br />

The new system puts <strong>GEA</strong> in some very<br />

good company. “Online application<br />

systems are common at big companies”,<br />

says Qinglin zhang. He only applies<br />

online. He gives the <strong>GEA</strong> <strong>Group</strong><br />

good marks: “i-Grasp is simple. It requires<br />

fewer forms and it has enough<br />

memory space for application papers.“<br />

Eryilmaz finds the <strong>GEA</strong> system more<br />

structured and in his eyes the color<br />

scheme is pleasantly restrained.<br />

nevertheless: interviews will<br />

always be indispensable<br />

Applicants receive confirmation of receipt<br />

immediately and will receive either an<br />

interview invitation or a rejection letter<br />

within 2 days. Despite all the electronic<br />

refinement, Kämpfert assures that: “the<br />

final decision will always be made in a<br />

face-to-face interview.”

22 | EmployEES<br />

Having fun with the music: the <strong>GEA</strong> Allstars. Their CDs help support needy employees of the <strong>GEA</strong> <strong>Group</strong> and their families.<br />

rEADy to roCk<br />

Jan Denis of grasso products b. V. who plays the trumpet in his spare time initially had the<br />

idea to form a band consisting of musicians from all over the gea group. the idea has become<br />

a lot more than just reality since. the gea allstars have already put out two CDs and now they<br />

have even had their first big public performance.<br />

take HoMe tHe<br />

gea allstars.<br />

you can order the band’s CDs<br />

from karin Harder at<br />

+49-(0)234 980-1276 or<br />

kidr@geagroup.com.<br />

price: 15 euros.<br />

Little did Denis know when<br />

he sent an email outlining<br />

his idea to <strong>GEA</strong> headquarters<br />

in Bochum in 200 that he<br />

would be making his stage<br />

debut just two years later.<br />

The <strong>GEA</strong> Allstars, consisting<br />

of twelve employees from<br />

Germany and the Netherlands<br />

plus a female vocalist,<br />

performed on June 2 at a<br />

public festival in Bochum.<br />

Spare-time rehearsals,<br />

ticket sales for a good<br />

cause<br />

Bochum had an open ear<br />

for Denis’ suggestion. <strong>GEA</strong><br />

promised to support him and publicized his idea in the former<br />

staff magazin. Eight musicians promptly answered the call<br />

and, under the direction of professional musician Peter ritter,<br />

they were soon making music together. The <strong>GEA</strong> Allstars were<br />

born. The band has since performed rock, pop and soul classics,<br />

spanning four decades. One of those occasions was at<br />

the <strong>GEA</strong> International Management Meeting in Copenhagen.<br />

“As they’re not commercial, the <strong>GEA</strong> Allstars have two big advantages:<br />

They can afford to be unconventional, working with<br />

amateur musicians as they do, and they can afford to have fun<br />

with the music,” explains ritter. Band members are ready to<br />

sacrifice their weekends or vacation days for rehearsals and<br />

performances. Even the proceeds from the sales of two CDs<br />

don’t end up in the band’s account alone. Instead, one portion<br />

goes to the <strong>GEA</strong> <strong>Group</strong> Assistance Fund e. V. (see boX).<br />

tHe gea group assistanCe<br />

FunD e. V.<br />

the gea group assistance Fund e.V. furnishes aid to<br />

needy employees of the gea group and their families<br />

in the form of money or materials. reasons for assistance<br />

can be a personal emergency, illness, accident,<br />

act of god or the death of an employee or close relative.<br />

applications for assistance must be made in writing<br />

and require the approval of the Fund’s board of<br />

Directors. please consult your Human resources Department<br />

or your works council, if you have any questions.<br />

the Works Council supports the i²M ideas and improvement Management system.<br />

i²m is dear to <strong>GEA</strong> <strong>Group</strong> Chairman<br />

Jürg oleas’ heart, even though<br />

it wasn’t his idea. the idea actually<br />

came from the <strong>Group</strong> Works<br />

Council. it represents a way for<br />

employees to supplement their<br />

income and secure their jobs.<br />

Jürg Oleas and reinhold Siegers, Chairman<br />

of the <strong>Group</strong> Works Council, have<br />

plenty of experience when it comes to<br />

balancing the interests of the group<br />

against those of employees. “We’re talking<br />

about a gold mine here, namely our<br />

people’s ideas. At the same time, the<br />

streamlining process will continue”, says<br />

Siegers. Oleas and Siegers came up with<br />

a solution in both instances, rewarding<br />

suggestions on the one hand and signing<br />

an agreement against downsizing on<br />

the other.<br />

A challenge for management<br />

The key to success is professional organization.<br />

“The success of I²M depends not<br />

only on guidelines being set down, but on<br />

creating a serious atmosphere in which<br />

people can express their ideas and find<br />

fertile ground”, says Siegers. He sees a<br />

task for management here. “They have<br />

to promote creativity and initiative on the<br />

part of employees. They have to motivate<br />

improvements and they have to lead by example.”<br />

That’s the only way to make employees<br />

aware of the virtues of profitability,<br />

quality and customer satisfaction. For the<br />

management, that means ‘spending a lot<br />

more time on employees.’ I²M has great<br />

potential to become a win-win-situation –<br />

enhanced competitiveness for the <strong>GEA</strong><br />

<strong>Group</strong> on the one hand, and job security<br />

plus bonuses for employees on the other.<br />

reinhold Siegers is curious about how the<br />

management is going to tackle this task.<br />

EmployEES | 2<br />

“nEW idEAS<br />

SErvE All”<br />

GrOUP WOrKS<br />

COUNCIL<br />

the group Works Council, under<br />

the leadership of reinhold Siegers<br />

(see piCture), coordinates codetermination<br />

on the part of the group’s<br />

workers. However, it has no authority<br />

over the local works councils.<br />

Deputies for siegers are klaus<br />

Hunger and Heinz Göersmeier.

2 | EmployEES EmployEES | 25<br />

anD tHe Winner is ...<br />

Lots of good ideas were submitted<br />

but there could only be one winner<br />

of this year’s Process Innovation<br />

Contest. Finally, the M-Division<br />

team edged out the competition. Its<br />

presentation on ‘simultaneous cost<br />

calculation’ in the design process<br />

swayed the jury, consisting of<br />

Division Presidents and Dr. Norbert<br />

Nieswandt. By way of reward,<br />

board member Peter Schenk (COO)<br />

handed a check for 250,000 EUr<br />

to Wilfried Mackel. The money has<br />

been earmarked to promote the<br />

proposal.<br />

Cool tools<br />

<strong>GEA</strong> Delbag Air Treatment<br />

GmbH will introduce an electrical<br />

filter system for purifying<br />

machine tool cooling lubricants<br />

at this year’s Hanover<br />

EMO from September 17 to<br />

22, 2007 (Hall 7, Stand E57).<br />

niels graugaarD<br />

MeMber oF tHe<br />

gea group eXeCutiVe<br />

boarD sinCe<br />

august 1<br />

Niels Graugaard, 0, president<br />

of the Process Engineering division,<br />

joined the <strong>GEA</strong> <strong>Group</strong> Executive<br />

Board with effect from<br />

August 1. He succeeds Peter<br />

Schenk who will be leaving our<br />

company on September 0 to<br />

take up a new position as CEO<br />

of the Viessmann <strong>Group</strong>. Niels<br />

Graugaard has headed the<br />

<strong>GEA</strong> <strong>Group</strong> company Niro A/S<br />

in Copenhagen, and therefore<br />

<strong>GEA</strong>‘s Process Engineering division,<br />

since 1999. As president<br />

of our largest division, he has<br />

provided important strategic input<br />

for the group as a whole in<br />

the past. With Niels Graugaard,<br />

the Executive Board will continue<br />

to pursue the same successful<br />

corporate strategy from which<br />

the group is already benefiting.<br />

Master WelDer<br />

Head trainer Henning Vache<br />

encouraged him to enter the<br />

competition for young welders:<br />

Apprentice Benjamin Behr (22)<br />

seized the opportunity to show<br />

what he could do. The <strong>GEA</strong><br />

Ecoflex apprentice welded his<br />

way to first place in Hildesheim<br />

and to second place in Lower<br />

Saxony. Congratulations!<br />

Foul play<br />

The gray geese who tapped<br />

on the window during a board<br />

meeting in Bochum showed<br />

disrespect for the Board of<br />

Directors and were accordingly<br />

refused entry. Now a fence has<br />

been erected to keep them at a<br />

respectful distance.<br />

Venerable<br />

Our mineral oil separators<br />

turn 100 this year. Labels on<br />

a workbench in the shipping<br />

department document previous<br />

jubilees, namely the 50th<br />

and the 75th.<br />

Congratulations!<br />

tHe streets are<br />

paVeD WitH golD<br />

Nobody knows for sure<br />

how many visitors have<br />

stopped to pick up the<br />

2-Euro coin in one of<br />

the rotunda staircases at<br />

company headquarters<br />

in Bochum. What we do<br />

know is that the coin was<br />

imbedded during renovation<br />

work. There must be<br />

something about it – it<br />

had to be replaced twice<br />

already.

2 | i²m i²m | 27<br />

i²m<br />

Dr. andreas risch, Head of the gea group’s i²M improvement Management program,<br />

talks about great ideas and great prizes.<br />

What is the potential of these improvement activities?<br />

Once you realize how much knowledge and experience 19,000<br />

experts can bring to the table, you can begin to imagine what<br />

the potential is. We intend to establish comprehensive idea and<br />

knowledge management in order to preserve and expand our<br />

knowledge base.<br />

i²m<br />

“We’re not talking<br />

about CoFFee Makers<br />

or WristWatCHes.“<br />

We’ve already got several improvement programs<br />

in the group such as r&d, tQm and kaizen. do we<br />

really need i²m?<br />

By all means. We need targeted improvement in different<br />

directions. This entails working with numerous different improvement<br />

projects. A continual improvement process such as<br />

I²M encourages new ideas among our employees and helps to<br />

manage those ideas.<br />

What’s the difference between the various<br />

approaches such as i²m, kaizen and the like?<br />

r&D (research & Development) and TQM (Total Quality Management),<br />

for instance, are strategically oriented. They concern<br />

the basics – products, markets, production, and machines. CIP<br />

and Kaizen stand for separate projects and continual improvement<br />

processes – mostly in manufacturing. This entails teamwork,<br />

frequently organized in workshops. I²M likewise relies<br />

on employees, but it takes their individual ideas into account<br />

for administration procedures, sales and areas beyond their<br />

immediate work environment.<br />

What’s in it for employees?<br />

To give you a short answer: they can earn quite a nice bonus.<br />

Imagine yourself making a suggestion that ends up paying for<br />

your vacation. What’s more, anyone who submits a suggestion<br />

automatically takes part in a drawing with some attractive prizes.<br />

And we’re not talking about about coffee makers or wristwatches<br />

here. Another benefit is for the job itself if the suggestion<br />

results in a simpler, faster or safer procedure.<br />

And what’s in it for the <strong>GEA</strong> <strong>Group</strong>?<br />

I²M increases the value of the company and makes us more<br />

competitive by mobilizing our knowledge, boosting innovation,<br />

optimizing wherever we can and promoting an atmosphere<br />