Humane-Slaughter-Guidelines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

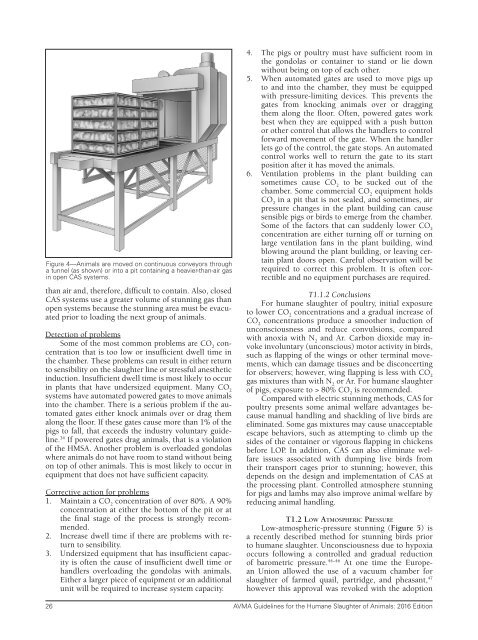

Figure 4—Animals are moved on continuous conveyors through<br />

a tunnel (as shown) or into a pit containing a heavier-than-air gas<br />

in open CAS systems.<br />

than air and, therefore, difficult to contain. Also, closed<br />

CAS systems use a greater volume of stunning gas than<br />

open systems because the stunning area must be evacuated<br />

prior to loading the next group of animals.<br />

Detection of problems<br />

Some of the most common problems are CO 2<br />

concentration<br />

that is too low or insufficient dwell time in<br />

the chamber. These problems can result in either return<br />

to sensibility on the slaughter line or stressful anesthetic<br />

induction. Insufficient dwell time is most likely to occur<br />

in plants that have undersized equipment. Many CO 2<br />

systems have automated powered gates to move animals<br />

into the chamber. There is a serious problem if the automated<br />

gates either knock animals over or drag them<br />

along the floor. If these gates cause more than 1% of the<br />

pigs to fall, that exceeds the industry voluntary guideline.<br />

34 If powered gates drag animals, that is a violation<br />

of the HMSA. Another problem is overloaded gondolas<br />

where animals do not have room to stand without being<br />

on top of other animals. This is most likely to occur in<br />

equipment that does not have sufficient capacity.<br />

Corrective action for problems<br />

1. Maintain a CO 2<br />

concentration of over 80%. A 90%<br />

concentration at either the bottom of the pit or at<br />

the final stage of the process is strongly recommended.<br />

2. Increase dwell time if there are problems with return<br />

to sensibility.<br />

3. Undersized equipment that has insufficient capacity<br />

is often the cause of insufficient dwell time or<br />

handlers overloading the gondolas with animals.<br />

Either a larger piece of equipment or an additional<br />

unit will be required to increase system capacity.<br />

4. The pigs or poultry must have sufficient room in<br />

the gondolas or container to stand or lie down<br />

without being on top of each other.<br />

5. When automated gates are used to move pigs up<br />

to and into the chamber, they must be equipped<br />

with pressure-limiting devices. This prevents the<br />

gates from knocking animals over or dragging<br />

them along the floor. Often, powered gates work<br />

best when they are equipped with a push button<br />

or other control that allows the handlers to control<br />

forward movement of the gate. When the handler<br />

lets go of the control, the gate stops. An automated<br />

control works well to return the gate to its start<br />

position after it has moved the animals.<br />

6. Ventilation problems in the plant building can<br />

sometimes cause CO 2<br />

to be sucked out of the<br />

chamber. Some commercial CO 2<br />

equipment holds<br />

CO 2<br />

in a pit that is not sealed, and sometimes, air<br />

pressure changes in the plant building can cause<br />

sensible pigs or birds to emerge from the chamber.<br />

Some of the factors that can suddenly lower CO 2<br />

concentration are either turning off or turning on<br />

large ventilation fans in the plant building, wind<br />

blowing around the plant building, or leaving certain<br />

plant doors open. Careful observation will be<br />

required to correct this problem. It is often correctible<br />

and no equipment purchases are required.<br />

T1.1.2 Conclusions<br />

For humane slaughter of poultry, initial exposure<br />

to lower CO 2<br />

concentrations and a gradual increase of<br />

CO 2<br />

concentrations produce a smoother induction of<br />

unconsciousness and reduce convulsions, compared<br />

with anoxia with N 2<br />

and Ar. Carbon dioxide may invoke<br />

involuntary (unconscious) motor activity in birds,<br />

such as flapping of the wings or other terminal movements,<br />

which can damage tissues and be disconcerting<br />

for observers; however, wing flapping is less with CO 2<br />

gas mixtures than with N 2<br />

or Ar. For humane slaughter<br />

of pigs, exposure to > 80% CO 2<br />

is recommended.<br />

Compared with electric stunning methods, CAS for<br />

poultry presents some animal welfare advantages because<br />

manual handling and shackling of live birds are<br />

eliminated. Some gas mixtures may cause unacceptable<br />

escape behaviors, such as attempting to climb up the<br />

sides of the container or vigorous flapping in chickens<br />

before LOP. In addition, CAS can also eliminate welfare<br />

issues associated with dumping live birds from<br />

their transport cages prior to stunning; however, this<br />

depends on the design and implementation of CAS at<br />

the processing plant. Controlled atmosphere stunning<br />

for pigs and lambs may also improve animal welfare by<br />

reducing animal handling.<br />

T1.2 Low Atmospheric Pressure<br />

Low-atmospheric-pressure stunning (Figure 5) is<br />

a recently described method for stunning birds prior<br />

to humane slaughter. Unconsciousness due to hypoxia<br />

occurs following a controlled and gradual reduction<br />

of barometric pressure. 44–46 At one time the European<br />

Union allowed the use of a vacuum chamber for<br />

slaughter of farmed quail, partridge, and pheasant, 47<br />

however this approval was revoked with the adoption<br />

26 AVMA <strong>Guidelines</strong> for the <strong>Humane</strong> <strong>Slaughter</strong> of Animals: 2016 Edition