Project Y

Project Y

Project Y

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

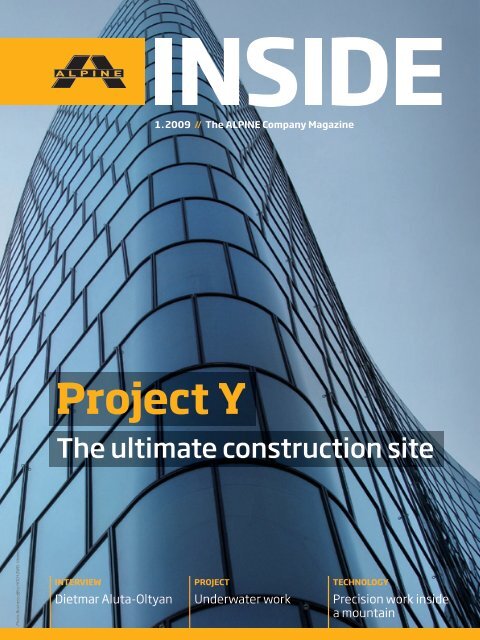

Photo: Business office HOCH ZWEI, Vienna<br />

<strong>Project</strong> Y<br />

The ultimate construction site<br />

INTERVIEW<br />

Dietmar Aluta-Oltyan<br />

1.2009 // The ALPINE Company Magazine<br />

PROJECT<br />

Underwater work<br />

TECHNOLOGY<br />

Precision work inside<br />

a mountain

Projekt Y<br />

Nördlich North of Vienna von Wien / Austria / Österreich<br />

SEITE PAGE 14

1.2009<br />

Andreas Eder<br />

ALPINE Head of Marketing<br />

Editorial<br />

Dear Reader,<br />

This is our first edition of INSIDE, the ALPINE company magazine.<br />

You may ask: What should a construction company tell me without getting bored after a few sentences?<br />

We have asked the same question. We cannot entertain you with stars and spectacular<br />

events. The radio furnishes you with the most important news every day and technical<br />

reports can be found in every professional journal. What is left to tell? Actually, it is very simple.<br />

Things, you simple have never heard before. Topics you always wanted to know more about.<br />

Minor details that will yet open up a surprising and wondrous world for you. The magazine will<br />

provide surprising insights into the world of ALPINE. No matter whether your are a technical<br />

expert or simply interested. And you will be surprised to see how much your life is influenced<br />

by construction.<br />

Our editorial will give you new insights into the first Austrian PPP road construction project in<br />

Austria which at the same time is the largest construction site in Central Europe. Let us impress<br />

you with technologies and innovations used for the construction of cooling towers at the coalfired<br />

power plant Neurath or read up on topics like economics, sustainability and safety.<br />

A report on the particularities of working in the Balkans gives you an insight into foreign<br />

countries and cultures. Find out more about this unusual sport cricket - quite an unusual sport<br />

in the German-speaking area and to ALPINE. However ALPINE has created new opportunities<br />

for this sport in an exotic location. Did you ever hear about professional divers? Do you know<br />

who is "Heidi" and "Sissi" and what they are doing in a tunnel? Did you ever taste wine from a<br />

concrete egg? We will answer all these questions and give you personal insights, tell you about<br />

lasting experiences and lead you into areas of fascinating research.<br />

Talented and enthusiastic editors made sure these pages are exciting and interesting to read.<br />

The magazine's layout was developed in-house and features the company's distinctive fresh<br />

and modern style. All issues are full in-house productions. With a good dose of passion we<br />

hope you feel.<br />

Enjoy reading it!<br />

03

COMPANY<br />

PROJECT<br />

MARKET<br />

TECHNOLOGY<br />

RESOURCES<br />

ENVIRONMENT<br />

//<br />

CONTENT<br />

06 An unused hour is a lost hour<br />

10 Underwater work<br />

14 The ultimate construction site<br />

19 Insights<br />

20 It's time for Viertel Zwei<br />

23 Close to the wind<br />

24 Including five-o'clock tea<br />

28 Sissi, Heidi and Gabi go on a journey<br />

30 Balkan Fever<br />

34 First milling train on tracks<br />

35 Insights<br />

36 Climb and press<br />

38 Precision work inside a mountain<br />

42 Glass beads for safety<br />

43 Insights<br />

44 It all began with a pork belly<br />

46 Using the sun's power<br />

48 Even the Romans would be amazed<br />

50 Constructive – Column by Alex Aichner<br />

50 Imprint<br />

The ALPINE Company Magazine<br />

Issue 1 / October 2009<br />

You can find more information at<br />

INSIDE.alpINE.at<br />

Ü

TOP TOPICS<br />

BRIDGE ACROSS THE DANUBE AT THE CITY OF TRAISMAUER<br />

Underwater work<br />

ALPINE constructs a new bridge across the river Danube at the city of<br />

Traismauer, located in Lower Austria. Professional divers are used for the<br />

first time in bridge construction and bridge piers are concreted with a<br />

special construction between two ships and not ashore - another first.<br />

10<br />

PROJECT Y<br />

The ultimate construction site<br />

‘<strong>Project</strong> Y’ is the first Public Private Partnership (PPP) project in Austria<br />

and located north of Vienna. This project is not merely demanding in terms<br />

of know-how but also in terms of logistics and project management.<br />

14<br />

CRICKET STADIUM DUBAI<br />

Including five-o’clock tea<br />

A typical game of cricket takes from four to five days and is never boring<br />

to fans. ALPINE constructed the new Dubai cricket stadium in only 28<br />

months. Its cross-vaulted roof style reminds of a ‘star in the desert’.<br />

24<br />

RECRUITING<br />

Balkan Fever<br />

The Balkan is the place-to-be for the ‘young and wild’ in the construction<br />

industry. In CEE and SEE countries many infrastructure projects are currently<br />

in progress. This requires highly qualified and motivated employees.<br />

30<br />

TUNNELLING<br />

Precision work inside a mountain<br />

Even though more machines and better and more modern technologies<br />

are being employed: tunnelling remains a dangerous and arduous task.<br />

Already in the midst of the 20th century three Austrians caused a revolution<br />

in tunnelling.<br />

38<br />

05

06 // COMPANY

»An unused hour<br />

is A lost hour«<br />

INTERVIEW He is ‘Mr. ALPINE’: Dietmar Aluta-Oltyan on success, responsibility, how<br />

he deals with failure and his family roots in Cisleithania.<br />

// clAUDiA lAgler<br />

You are at the helm of ALPINE for<br />

more than 40 years. What is it that<br />

fascinates you in construction?<br />

Building means designing and<br />

creativity. You can realize your<br />

ideas. I like it a lot.<br />

In your opinion, what caused<br />

ALPINE to become the secondlargest<br />

Austrian construction<br />

group? What is your share in<br />

this success?<br />

I have devoted my life to ALPINE.<br />

ALPINE was 11 million Austrian<br />

Shillings in debt when I joined<br />

in 1968. I saw a chance to build<br />

an expand a company employing<br />

better ideas, quicker reaction and<br />

skill. I enjoy taking responsibility<br />

and leading people. This was a key<br />

requirement to achieve what we<br />

have today.<br />

ALPINE is synonymous with top<br />

quality and reliability. There is no<br />

project that we did not complete.<br />

Not a bad achievement in 41 years.<br />

In your opinion, what are the<br />

most fascinating projects today?<br />

Infrastructure projects always deal<br />

with mountains and nature. In any<br />

event this is more exciting than<br />

constructing a high-rise building.<br />

Even though a high-rise building<br />

can be quite demanding, particularly<br />

in regards to its foundation.<br />

You never know what you will find<br />

when you start digging in Berlin’s<br />

sandy ground or in Salzburg’s<br />

lacustrine clay.<br />

Is there a project that you find<br />

particularly tempting over the<br />

next few years?<br />

Since 2001 we work on the St.-<br />

Gotthard tunnel. This project will<br />

be completed in 2017 only. Running<br />

a construction site for 15 or 16 years<br />

is a challenge, whichever way you<br />

look at it. The Brenner base tunnel<br />

is a project where ALPINE should<br />

take on a leading role. Let’s see<br />

whether we will be successful.<br />

We are fascinated by an unusual<br />

project. The main problem is that an<br />

engineer, with all the excitement,<br />

tends to construct a wonderful<br />

building while underestimating the<br />

economics and risk involved.<br />

A prime requirement for success<br />

seems to be the coordination of<br />

technical feasibility and profitability.<br />

Is that correct?<br />

Well, it is typical for this industry to<br />

not only run profitable construction<br />

sites. Many companies in the past<br />

have been known for this and collapsed.<br />

In the end we bought many<br />

of them. There is a saying: Grow by<br />

getting smaller. When it comes to<br />

acquisitions you don’t get two by<br />

adding one plus one. You only get<br />

1.8. To be successful you have to say<br />

good bye to some bad parts.<br />

07

08 // COMPANY<br />

»When it comes to acquisitions<br />

you don‘t get tWo by adding one plus one.<br />

you only get 1.8.«<br />

You hardly ever give interviews and<br />

you hardly ever to never mix with<br />

those that make it into the tabloid<br />

news. How would you describe<br />

Dietmar Aluta-Oltyan as a person<br />

to someone who doesn’t know you?<br />

In my opinion the press only<br />

produces bad news about the<br />

construction industry. The media<br />

should be more concerned with<br />

how to build a national economy<br />

rather than to damage it. The<br />

construction industry plays an important<br />

role in the development of a<br />

nation and is its engine in a boom.<br />

What about the person Dietmar<br />

Aluta?<br />

My motto is: When a problem needs<br />

to be solved you must tackle it and<br />

be willing to take some risks and<br />

not be too worried about whether<br />

or not it will come out alright. I<br />

take on a task. It is better to make<br />

a wrong decision than to not make<br />

a decision at all. I like my job. I<br />

identify with the company and that<br />

rubs off on others as well.<br />

You were born in Bad Hall in<br />

Upper Austria. Where does your<br />

rather unusual family name come<br />

from?<br />

My grandfather came from Cisleithania<br />

and was general director<br />

of the Austrian Lloyd’s company<br />

in Constantinople. The name itself<br />

has its origin in Romania. And still<br />

today you will find a county named<br />

Oltyan with a river named Aluta.<br />

My father moved to Austria, studied<br />

in Salzburg and Graz and married<br />

an Austrian girl.<br />

Do you have something like a<br />

motto in life?<br />

An unused hour is a lost hour.<br />

Have there been ideals that were<br />

or are import to you?<br />

When I started I have been surrounded<br />

by supposedly big names.<br />

They only smiled at the ambitious<br />

plans of the boy Aluta. Today, none<br />

but one of these names still exists.<br />

I managed to make my way. This<br />

might even have been an incentive<br />

behind ALPINE’s development.<br />

You were one of those that soon<br />

recognized the opportunities<br />

offered by the Eastern European<br />

markets. How come?<br />

We started rather early in Croatia.<br />

We planned a motorway in the<br />

beginning of the 1980s. Unfortunately,<br />

war interrupted the project.<br />

Even before the wall fell we started<br />

to work in East Germany. These<br />

early projects told us what mistakes<br />

to avoid.<br />

For instance: we never have bought<br />

an East-German construction<br />

company. We only took over the<br />

best people and not the burdens of

1944 1963 1968 2005 2006 2008<br />

Dietmar Aluta-<br />

Oltyan was born<br />

on June 25th in the<br />

city of Bad Hall.<br />

Matura (general<br />

qualification for<br />

university entrance)<br />

at the<br />

Polytechnic Institute<br />

in foundation<br />

engineering in the<br />

city of Krems.<br />

the past. From the very beginning,<br />

our East-European strategy was to<br />

build a local company with the help<br />

of a big project. That company was<br />

supposed to work independently as<br />

much as possible and without support<br />

from Austria. This worked out.<br />

What comes next in the East?<br />

There are many false expectations<br />

linked with the East. What applies<br />

at home applies there as well:<br />

You can make - sometimes only a<br />

small - profit but only if you deliver<br />

excellent service. But it is also true<br />

that these countries have an enormous<br />

amount to catch up when<br />

compared with West-European<br />

standards. They provide excellent<br />

opportunities.<br />

Looking back, what do you consider<br />

the biggest success in your life?<br />

It depends on what situation you<br />

are in. When I started it was a<br />

Joining the company<br />

(11 million<br />

Austrian Shillings<br />

in debt at that<br />

time – about<br />

€ 800,000).<br />

Advancing to<br />

managing partner<br />

at ALPINE Holding<br />

GmbH.<br />

big success to earn 100 Austrian<br />

Shillings. Today the amounts are<br />

different. I was lucky to have many<br />

successes and hope there are still<br />

many more to come.<br />

How do you cope with failure and<br />

disappointments?<br />

Failure is part of life and shapes<br />

a person. Failure never really<br />

threw me off balance. It rather<br />

caused me to be more determined.<br />

A battle is lost only once the last<br />

man died.<br />

What are your ambitions for the<br />

next few years?<br />

My objective is to organize<br />

ALPINE so that it works perfectly<br />

without my immediate operative<br />

involvement. We are well on<br />

our way to achieve it. I will assist<br />

ALPINE with my knowledge<br />

and experience as long as I enjoy<br />

doing it.<br />

Partner and<br />

chairman of the<br />

supervisory board<br />

of ALPINE Holding<br />

GmbH.<br />

40th anniversary<br />

at ALPINE for<br />

Dietmar Aluta-<br />

Oltyan.<br />

What about your private life?<br />

I am happy. I spend a lot of time<br />

with my grand children and with<br />

sport. Alpine touring and deepsnow<br />

skying in winter. Swimming,<br />

tennis, fast cars and mountain<br />

hiking in summer. I have tried all<br />

kinds of sport but riding and golf.<br />

How important is your home country<br />

and roots in this region to you?<br />

I love Salzburg and the region Salzkammergut.<br />

It is my home. Take<br />

away some of the rain and it is the<br />

most beautiful country on earth.<br />

Thank you for this interview! //<br />

09

10 //<br />

PROJECT<br />

Underwater<br />

work<br />

BUT ONLY FOR THOSE WITH NEVERS OF STEEL ALPINE constructs a new bridge<br />

across the river Danube at the city of Traismauer, located in Lower Austria. Only real pros<br />

work at or under the water.<br />

// clAUDiA lAgler

Supporting formwork of ‘Danube bridge Traismauer’<br />

I<br />

t was as short and simple<br />

a task for Viennese<br />

Peter Haberhauer as the<br />

construction site was spectacular:<br />

The professional diver and his<br />

team went under water to ready<br />

the floating hollow piers of the new<br />

Danube bridge at Traismauer for<br />

their transport to their final position.<br />

A job for underwater professionals:<br />

One divers removes the<br />

cables that held the piers to the<br />

construction boats. The ALPINE<br />

specialists were next. The many<br />

tons of pier shells were floated to<br />

their predetermined position and<br />

lowered. “It was precision work and<br />

it worked perfectly” said construction<br />

site manager Peter Jungbauer<br />

about one of the most exciting moments<br />

on the construction site on<br />

the river Danube.<br />

ALPINE works since autumn 2007<br />

on the Danube bridge at Traismauer.<br />

It is the heart of a new road link<br />

between the Kremser dual car-<br />

riageway S 33 and Stockerauer dual<br />

carriageway S 5. The contract section<br />

covers the Danube bridge itself<br />

and two foreshore bridges north<br />

and south of the river - a section of<br />

more than one kilometre in length.<br />

ALPINE is the sole trader for the<br />

entire project. This is quite uncommon.<br />

Innovative procedures used<br />

by ALPINE for the construction of<br />

the Danube bridge played their part<br />

in the Salzburg company winning<br />

this project over five tough competing<br />

syndicates.<br />

Pier construction in<br />

the river<br />

An example of a new construction<br />

method: For the first time bridge<br />

piers are concreted with a special<br />

construction between two ships<br />

and not ashore. The water’s uplift<br />

carried the final concreted pier<br />

shells. “For this to work we had to<br />

develop detailed construction-phase<br />

plans and the weight of individual<br />

components had to be minutely calculated”<br />

Jungbauer tells us. Once the<br />

shells were ready the divers had to<br />

come in. They had to assist in floating<br />

the piers to their final position.<br />

For the first time bridge piers<br />

are concreted with a special<br />

construction between two ships<br />

and not ashore.<br />

The Viennese professional diver<br />

Haberhauer was excited to be part<br />

in the construction of this bridge<br />

across ‘his river’. The 60-year-old<br />

has thousands of hours of diving<br />

experience - and therefore mainly<br />

stays ashore. “The best has to stay<br />

ashore to help in case of emergencies”<br />

Haberhauer explains. Diving is a<br />

teamwork: one man is in the water,<br />

another is at the cable and tools and<br />

11

12 //<br />

PROJECT<br />

Professional divers<br />

The Austrian company ‘WiFi Oberösterreich’ offers<br />

courses for professional divers in cooperation with<br />

the ‘Tauchschule Nautilus’ (diving school) in the city<br />

of Weyregg at the lake Attersee. A qualifying exam<br />

is a must before anyone is accepted to this course.<br />

ideally a professional qualification (such as locksmith,<br />

metalworker or woodworker) is part of the applicant‘s<br />

portfolio – quite in addition to the enthusiasm for diving.<br />

The water is always ready for extra challenges in<br />

addition to the technical task at hand: strong currents,<br />

low temperatures, bad visibility. Diving is possible at<br />

any hour of the day or night. A single diving trip may<br />

not exceed four hours in length. Professional diving is<br />

very exhaustive and the equipment heavy. There are<br />

always teams of at least three people in diving.<br />

Ü www.NautIluS.at ooE.wIfI.at www.tauchEr.at<br />

yet another provides communication<br />

and oxygen.<br />

Bridge Piers instead of<br />

coral reefs<br />

Professional diving has little in<br />

common with excursions to coral<br />

reefs or romantic fishing grounds. If<br />

you want to go under water professionally<br />

you need good vocational<br />

skills, stamina, strong nerves and<br />

calmness. Professionals do not only<br />

dive at bridge construction sites like<br />

Traismauer. They work at power<br />

stations, reservoirs, sewage treatment<br />

plants, wells or excavation<br />

pits. They examine, drill, weld, cut<br />

- always in a hostile environment<br />

under water. Most of the time it is<br />

pitch black and cold. “Being a good<br />

skin diver doesn’t necessarily mean<br />

one is fit for professional diving” ex-<br />

Diving is a<br />

teamwork and<br />

the best stays<br />

ashore.<br />

plains Haberhauer who runs a team<br />

of freelancers.<br />

The divers were a tiny little wheel at<br />

this above-water and under-water<br />

construction site. Up to nine ships<br />

were used to construct the piers<br />

and the supporting framework in<br />

the river Danube. Two pontoons<br />

were anchored about 40 m from the<br />

river bank and formed a floating<br />

pier construction site. It was kind of<br />

a working raft. Additionally a transept<br />

was anchored nearby. The new<br />

kind of pier construction procedure<br />

had distinct advantages: only little<br />

space was needed on the banks<br />

- after all, this area called Auwald<br />

was part of the ‘Natura-2000’ nature<br />

protection area.<br />

new cantilever<br />

construction techniques<br />

The piers are solidly anchored in the<br />

water. To ALPINE employees this<br />

meat leaving the ship and working<br />

way up high. The supporting<br />

formwork of the bridge is constructed<br />

piece by piece in the classic<br />

cantilever construction method<br />

about 20 m above the water. For<br />

the first time in Austria, ALPINE<br />

uses newly developed DOKA cantilever<br />

construction carriages for<br />

the construction of the supporting<br />

formwork. What is so special about<br />

it? Four cantilever construction<br />

carriages simultaneously build the<br />

supporting formwork in both directions.<br />

Drivers will have two separate<br />

carriageways comprised of a<br />

driving lane and a service lane once<br />

the construction is complete.

“Simultaneous<br />

construction of<br />

supporting formwork<br />

in both directions.”<br />

Peter Jungbauer<br />

Construction site<br />

manager<br />

, INSIDE.alpine.at<br />

workPlace with a view<br />

An experienced team works on the<br />

supporting formwork. Everyone<br />

knows exactly what to do. Every<br />

week 3.15 to 5.20 metre long sections<br />

of the supporting formwork<br />

are constructed on both sides of the<br />

bridge pier. Advancing, formwork,<br />

reinforcement, concreting, hardening,<br />

pre-stressing - every step is<br />

precisely planned. This workplace<br />

provides an amazing view across<br />

the meadow land. A bit of a holiday<br />

feeling creeps into breaks - at<br />

least when the weather is nice. Below<br />

you the flowing river, bicycle<br />

riders on the Treppelweg road<br />

and beavers, herons or swans along<br />

the river banks. Large ships pass<br />

the construction site regularly -<br />

the Danube must be open for traffic<br />

throughout the entire construc-<br />

1,129.60 m<br />

total Bridge length<br />

31.5 m<br />

total Bridge width<br />

19/11/2007<br />

Begin of construction<br />

11/11/2010<br />

oPening for traffic<br />

€ 48.73 Million<br />

order value<br />

20 km<br />

travel distance saved for<br />

coMMuters<br />

tion period. “The sheer dimensions<br />

of this project make it quite unusual”<br />

Jungbauer says proudly. This is<br />

the largest bridge construction site<br />

managed by the 30-year old Linzer<br />

together with general construction<br />

site manager Franz Almeder and<br />

foreshore-bridge construction site<br />

manager Robert Avender. The Danube<br />

bridge will be opened for traffic<br />

in November 2010. That’s the end<br />

of a task for professional divers at a<br />

spectacular construction site. And a<br />

end for all the other workers too. //<br />

SHORTCUTS<br />

13<br />

PROTECTING TOADS, LURCHS<br />

& CO. unusual tasks for construction<br />

worker: A construction worker went<br />

out every day during the spawning<br />

season in spring to collect amphibians<br />

that fell into buckets along the safety<br />

fence and carried them to the other<br />

side of the construction site. number<br />

and types of amphibians were carefully<br />

recorded. these tasks were part of<br />

the requirements set by the environmental<br />

impact Assessment (eiA). A<br />

nature-2000 nature protection area<br />

was affected by the construction site<br />

along the river danube. this required<br />

that construction works paid great<br />

attention to the habitats of fauna and<br />

flora. Construction was only allowed<br />

from sunrise to sunset to not destroy<br />

the chronobiology.<br />

COMMUTERS SAVE<br />

20 KILOMETRES the new danube<br />

bridge at traismauer improves accessibility<br />

of Central lower Austria and part<br />

of the so-called regional-ring-north.<br />

it provides an efficient axis between<br />

stockerauer dual carriageway s 5 and<br />

the Kremser dual carriageway s 33<br />

and leads to the Westautobahn A1<br />

(motorway). this reduces the route for<br />

commuters by 20 kilometres.

14 //<br />

PROJECT

The ultimate<br />

construction site<br />

LEADING THE WAY The very first PPP road construction project in Austria in being<br />

created north of Vienna. This mega project places special challenges to logistics and project<br />

management in addition to constructing a host of buildings.<br />

// clAUDiA lAgler<br />

// iNeS ScHMieDMAier<br />

15

16 // PROJECT<br />

kilometres of road, 76<br />

bridges, 4 tunnels, 13,000<br />

51 plans, 60,000 tons of<br />

steel, 1.6 million cubic metres of<br />

concrete, up to 1,300 workers and<br />

an investment sum of 933 million<br />

Euro: This are some of the key data<br />

of the currently largest construction<br />

site in Central Europe. A new<br />

road link is constructed in the region<br />

Weinviertel located in Lower<br />

Austria: <strong>Project</strong> Y, PPP Eastern Region<br />

Package 1. The dimension of<br />

this construction site is not the only<br />

extraordinary aspect but also the<br />

type of financing for this new road<br />

link. <strong>Project</strong> Y is the first Public-<br />

Private-Partnership road construction<br />

project in Austria. The name<br />

‘<strong>Project</strong> Y’ symbolizes the visual<br />

appearance of the three road links,<br />

forming the shape of the letter Y<br />

standing on its head.<br />

an end to traffic jaMs<br />

The new roads should make an end<br />

to the daily traffic jams north of Vienna.<br />

The Brünner Street B7 is used<br />

daily by about 20,000 vehicles. Severe<br />

accidents are a daily occurrence<br />

on this extra-wide country<br />

road. “Since the 2004 enlargement<br />

of the European Union the traffic dramatically<br />

increased in the villages<br />

along the street B7. The burden on the<br />

population is simply no longer acceptable”<br />

says ombudsman and local<br />

politician Erwin Pollany, knowing<br />

about the problems of the abutting<br />

population. The new motorway section<br />

and the two dual carriageways<br />

will considerably improve the safety<br />

and quality of life in this region<br />

and ensure a drastically faster connection<br />

to the Weinviertel region<br />

and the city of Vienna.<br />

construction Period:<br />

three Years – useful life:<br />

three decades<br />

In 2003 the company ASFINAG began<br />

preparations for this megaproject.<br />

In 2005 a pan-European<br />

tender procedure for the PPP<br />

<strong>Project</strong> took place. On December<br />

12, 2006 the company Bonaventura<br />

Straßenerrichtungs-GmbH won the<br />

planning, construction, financing<br />

and operation of this roadway for a<br />

30-year term.<br />

This company was founded specifically<br />

for this project. It is composed<br />

of ALPINE Bau GmbH, the<br />

German company HOCHTIEF PPP<br />

Solutions GmbH and the French<br />

infrastructure construction company<br />

Egis <strong>Project</strong>s SA. ALPINE Bau<br />

GmbH runs the company Arge

A container village in the city of Großebersdorf is the temporary workplace for about 130 employees.<br />

PPP Ostregion that is responsible<br />

for the construction of PPP Eastern<br />

Region Package 1. ALPINE and<br />

HOCHTIEF Construction AG have<br />

equal shares in this company. BonaventuraStraßenerrichtungs-GmbH<br />

will operate the roadway for a<br />

30-year term. The three companies<br />

mentioned above make up this<br />

company.<br />

first PPP infrastructure<br />

<strong>Project</strong> in austria<br />

Since a few years the Public Private<br />

Partnership is a model of cooperation<br />

employed by governments<br />

and private companies for important<br />

infrastructure and public utility<br />

projects. The PPP Eastern Region<br />

Package 1 is the first road construction<br />

project in Austria executed by<br />

way of a PPP model. ASFINAG instructed<br />

a private company – Bonaventura<br />

– to finance, construct<br />

and operate this road link on a<br />

long-term basis. In return ASFINAG<br />

pays a monthly ‘availability fee’<br />

throughout the 30-year term. A<br />

so-called shadow toll (i.e. a toll not<br />

paid by the driver but by the government<br />

to Bonaventura) is added<br />

and calculated on the basis of the<br />

number of vehicles and number of<br />

kilometres driven. The availability<br />

fee is reduced if a lane or carriageway<br />

is temporarily out of order and<br />

unusable.<br />

extensive logistics and<br />

a tight schedule<br />

A project of this size not only requires<br />

technical know-how and<br />

expertise. Arno Piko, technical<br />

managing director of Arge PPP Ostregion<br />

points out that the biggest<br />

challenges of this mega construction<br />

site are its tight schedules and<br />

extensive logistics.. The first section<br />

will be opened for traffic in November<br />

2009 and further sections in<br />

January 2010 - after three years of<br />

construction only.<br />

In some parts this construction site<br />

requires enormous quantities of<br />

technicalities, machines and personnel.<br />

During some peak periods a<br />

total of four mobile concrete mixing<br />

plants operated at this construction<br />

site with an hourly output of more<br />

than 700 cubic metres of concrete.<br />

Temporary workplaces were built<br />

for employees who permanently<br />

work at this construction site. During<br />

the construction period some<br />

100 to 130 employees had their<br />

workplace in the so-called ‘container<br />

village’. It consists of 240<br />

construction-site container that are<br />

interconnected on two levels with<br />

hallways and stairways. Conference<br />

rooms, kitchens, sanitary facilities<br />

and a service room are spread over<br />

a space of 3,000 m2. It even features<br />

Responsible for smooth operation: Arno Piko,<br />

<strong>Project</strong> Manager at ARGE Region Ost<br />

a reception area and one employee<br />

is always present and responsible<br />

solely for maintaining its IT infrastructure.<br />

A proprietary data and planning<br />

management system enables and<br />

ensures excellent communication<br />

between all members of the project.<br />

After all: this construction site requires<br />

some 12,000 to 13,000 plans.<br />

“All plans placed side by side would fill<br />

one-and-a-half soccer fields” Piko<br />

17<br />

The PPP Eastern<br />

Region Package 1<br />

comprises a great<br />

many different<br />

buildings –<br />

currently the<br />

largest construction<br />

site in<br />

Central Europe.

18 // PROJECT<br />

SHORTCUTS<br />

PPP A Public Private Partnership is a partnership between<br />

government and private industry to realize public projects. in<br />

most cases the private partner takes over the project‘s planning,<br />

financing, construction and operation and in return<br />

receives a fee.<br />

PPP AWARD in 2007 the company Bonaventura straßenerrichtungs-Gmbh<br />

and AsFinAG received the international<br />

Public Private Finance Award ‘Best european <strong>Project</strong> to sign’<br />

for the PPP eastern region Package 1. the international<br />

road Federation awarded the project the ‘Most innovative<br />

Finance Award’ and the euromoney <strong>Project</strong> Finance<br />

Magazine awarded the title ‘european transport roads deal<br />

of the Year’.<br />

points out with an impressive comparison.<br />

gPs-controlled excavator<br />

for heavY-dutY earthwork<br />

This construction site offered numerous<br />

challenges for engineers.<br />

These were quite in addition to demanding<br />

requirements on project<br />

management. “On this construction<br />

site we have to deal with everything<br />

the construction industry has to offer”<br />

Piko happily comments on the great<br />

variety of tasks: Streets, tunnels,<br />

bridges, sags, basins, noise barriers,<br />

service areas. This protect even includes<br />

the first mined tunnel in the<br />

Weinviertel region: the Tradenberg<br />

tunnel in the municipal district of<br />

Hagenbrunn/Königsbrunn.<br />

A total of 10.3 million cubic metres<br />

of earth must be moved to build<br />

the many buildings. To achieve this<br />

ARGE employs the latest in technology:<br />

Quite a number of survey<br />

teams are replaced by GPS. The<br />

driver of an excavator can see the<br />

future roadway on a screen and follows<br />

this virtual line with GPS support.<br />

The result: “We have achieve a<br />

PROJEKT Y PPP EASTERN REGION PACKAGE 1<br />

The project is composed of the dual carriageway<br />

S1 from the city of Korneuburg to the city of<br />

Eibesbrunn and from the city of Süßenbrunn<br />

to the city of Eibesbrunn as well as the dual<br />

carriageway „Wiener Nordrand“ S2 bypass<br />

Süßenbrunn. The dual carriageways S1 and S2<br />

join the northern motorway A5 at the city of<br />

Eibesbrunn. Once complete it will lead from<br />

Eibesbrunn to the city of Schrick<br />

Korneuburg S1<br />

very high heavy-duty-earthwork output<br />

with fewer personnel” Piko said.<br />

To be able to work as precisely as<br />

possible eight transmitters installed<br />

at the construction site correct the<br />

diffusion usually present in common<br />

GPS systems. “We have developed<br />

a reference system that reduces<br />

the usual deviations in GPS systems of<br />

two to five metres to two to three centimetres”<br />

Arno Piko explained.<br />

environMentallY designed<br />

noise Barriers<br />

Noise barrier walls and embankments<br />

and tunnels ensure that people<br />

living near the roadway are affected<br />

by the effects of traffic as<br />

little as possible. The noise barriers<br />

follow a uniform design - as does<br />

the entire project.<br />

The design of service areas, overpasses<br />

and noise barriers were<br />

meant to reflect the look of the<br />

Waldviertel region. Particular attention<br />

was paid to achieve a visual<br />

integration with this environment.<br />

Rounded elements and light, flowing<br />

forms are employed. Light-col-<br />

S2<br />

Wolkersdorf<br />

Eibesbrunn<br />

S1<br />

Mistelbach<br />

A5<br />

Süßenbrunn<br />

A5<br />

Schrick<br />

oured and wavy silhouettes integrate<br />

with the country side.<br />

Many aspects had to be considered<br />

in the planning of the noise<br />

barriers: “To prevent a tunnel effect<br />

on the driver with the resulting<br />

tiredness noise barriers had to have<br />

a non-uniform design. On the other<br />

hand, changes may not occur to fast<br />

to avoid irritation” Martin Wakonig<br />

explained. He is responsible<br />

for the Environmental Design of<br />

<strong>Project</strong> Y. The solution was flowing<br />

transitions. Different types of rock<br />

matching the environment in the<br />

Weinviertel region were used for<br />

steep faces and so creates the impression<br />

of a typical hollow way in<br />

this area.<br />

Once the A5 motorway section between<br />

junction Eibesbrunn and<br />

Schrick is completed the next section<br />

between the cities Schrick and<br />

Poysdorf will be constructed. The<br />

last section to be built will be the<br />

motorway A5 to the city of Drasenhofen.<br />

In 2013 the motorway A5<br />

will reach the boarder of the Czech<br />

Republic, provided everything<br />

works according to plan. //

insights<br />

PAGE 20 PAGE 30<br />

DIVA-Award<br />

Since 2002 the annual ‘DIVA-Award’<br />

is awarded in Vienna to exceptional<br />

Austrian real estate projects. The<br />

criteria evaluated are architecture,<br />

innovation, profitability, marketing<br />

and how well the real estate<br />

is rented out. In 2008 IC Projektentwicklung<br />

GmbH was happy to<br />

receive this award for ‚HOCH ZWEI‘<br />

and ‚PLUS ZWEI‘.<br />

Hydropower stations generate<br />

18 % of the world‘s electrical<br />

energy. This is almost exactly the<br />

same amount generated by nuclear<br />

power plants<br />

PAGE 24 PAGE 24<br />

red / hard / fast PAKISTAN<br />

CONVERSATION<br />

A cricket ball weighs from 155-163 g, has a cork<br />

core and is tightly wrapped in rope. Its envelope<br />

consists of four pieces of leather joined by<br />

a slightly raised seam. The ball‘s circumference<br />

measures from 22.4–22.9 cm. The traditional<br />

colour of a cricket ball is dark red. Dangerous<br />

situations may arise due to the ball‘s hardness.<br />

Fielders close to the batsman commonly wear<br />

helmets with face protection.<br />

CNC<br />

Computerized Numerical Control is used<br />

since the mid 1970‘s. CNC is an electronic method<br />

to steer and control machine tools and/or devices<br />

used for this purpose. This allows streamlining mass<br />

and single-part production.<br />

PAGE 34<br />

PAGE 28<br />

THE GIANT<br />

What are the languages spoken<br />

in Pakistan?<br />

Note: English is also in widespread use.<br />

Rotterdam is the most important European container port and handles<br />

about 9.3 million TEU (Twenty-foot Equivalent Unit – a standard<br />

container). It sits at the world‘s most heavily used waterway. Ships with<br />

a draft of up to 24 metres can access it. The Port of Rotterdam and its<br />

related economy provide about 320,000 jobs of which about 60,000<br />

will be found in the immediate port area. The port area itself stretches<br />

for almost 40 km from the city of Rotterdam to Hoek van Holland and<br />

almost covers an area of 100 km².<br />

PAGE 20<br />

viennese Prater<br />

Official language Urdu // 08 %<br />

Sindhi, Balutschi, Pandschabi // 48 %<br />

Paschtu // 08 %<br />

Saraiki // 10 %<br />

Hindko // 02 %<br />

The most famous attraction is the Ferris wheel. The Wurstelprater aka<br />

Viennese Prater aka Volksprater (People‘s Prater) offers even more. It‘s<br />

an amusement park with many opportunities to wine and dine. Take one<br />

of the many booths or choose the traditional dish of ‘Stelze’ (knuckle of<br />

pork) and beer at the restaurant Schweizerhaus.

20 // PROJECT<br />

it’s time for<br />

viertel<br />

zwei

VIERTEL ZWEI is a quiet and green oasis in the midst of this business area. One of its quality features is its<br />

excellent infrastructure.<br />

BUSINESS ‘HOCH ZWEI’ The Prater has been an area for innovative building<br />

ever since the Austrian Emperor Franz Joseph. In his days it was the largest cupola<br />

in the world. Today it is an intricately designed city project called VIERTEL ZWEI.<br />

// iSAbellA DrAkUlic<br />

S<br />

omething special is in the air when one is<br />

heading toward the inner city and crosses<br />

the Viennese bridge named Reichsbrücke.<br />

The flagship HOCH ZWEI dominates and sticks out of<br />

its surrounding buildings with a blue-grey glass façade<br />

and an impressive architectural design.<br />

VIERTEL ZWEI is the new city district in the 2nd municipal<br />

district of Vienna. It has been created between<br />

the famous amusement park ‘Wurstelprater’ and the<br />

fair ground to the west, the harness racing track Krieau<br />

and the ‘Grüner Prater’ (‘Green Prater’) in the east, an<br />

very popular excursion place with the Viennese population.<br />

the Prater has an eventful historY<br />

This area saw a time of prosperity already. This was<br />

in 1873 when the Austrian Emperor Franz Joseph inaugurated<br />

the Vienna World Fair and 53,000 exhibitors<br />

hoped between May and November for their lucky<br />

strike on this huge fair ground. Already at that time<br />

constructions were innovative. The Rotunde, the land-<br />

mark of the world fair, was the largest doomed structure<br />

of its time with a height of 84 metres and an astonishing<br />

diameter of 108 metres. A fire in 1937 completely destroyed<br />

the Rotunde. Today, the main building of the Vienna<br />

Fair (southern portal) stands in its place.<br />

The world fair had a lasting effect on Vienna’s urban development.<br />

The entire area became a giant construction site<br />

in preparation for this event: the first training of the river<br />

Danube, the opening of the Vienna water pipeline and extensions<br />

to the train and road network changed the city<br />

into an international metropolis.<br />

right in Middle of the citY and Yet in<br />

the countrY side<br />

The Red Cross, a florist and the ARBÖ (the Austrian car,<br />

motorbike and bicycle association) building occupied part of<br />

this area before visionary and builder Michael Griesmayr<br />

discovered it about seven years ago behind the Vienna<br />

fair ground. The remaining area was a fenced in ‘concrete<br />

desert’. An extension to the tube (line U2) was in planning<br />

only.<br />

21

22 // PROJECT<br />

Today, one of the most successful and most innovative<br />

office and green projects in Vienna exists on this roughly<br />

40,000 m² space: the city development area VIER-<br />

TEL ZWEI. The 80 metre high office building HOCH<br />

ZWEI by the architects Henke and Schreieck and the<br />

neighbouring building PLUS ZWEI designed by architect<br />

Martin Kohlbauer caused quite a stir.<br />

Typical design elements of HOCH ZWEI are the concave-convex<br />

footprint and its transparent architecture,<br />

mostly using glass and steel. The angular design of the<br />

33 m high PLUS ZWEI building forms a counterpart to<br />

the powerful HOCH ZWEI tower. A high degree of natural<br />

light (remarkable 75 %) creates a pleasant office<br />

feeling in the new headquarters of the OMV group.<br />

Another impressive and unique aspect this project is<br />

the green space and the lake. Use the lunch break for a<br />

picnic or a walk around the lake. Relaxation and recreation<br />

right at your workplace with a green view - right<br />

in the middle of a city.<br />

successful overall concePt<br />

The success is based on a well-thought through overall<br />

concept. The decision to build an office district was<br />

substantially affected by the planned extension of the<br />

tube (line U2). Key points in the success of renting out<br />

VIERTEL ZWEI are its ideal traffic links, the good connections<br />

with public transportation and the integration<br />

with the main traffic routes of Vienna. A 100 % utilization<br />

has been achieved even before construction begun.<br />

This was due to the location and the flexible floor plan.<br />

In 2008 the landmark building HOCH ZWEI and the<br />

immediately adjacent PLUS ZWEI received the DIVA<br />

Visuals of VIERTEL ZWEI / © beyer.co.at<br />

&<br />

FACTS FIGURES<br />

Vorgarten street / Trabrenn<br />

street (krieau district),<br />

1020 Vienna, Austria<br />

Area: ca. 40,000 m²<br />

rentable space: ca. 92,000 m²<br />

Area covered by water: 5,000 m²<br />

Jobs: 3,000 – 4,000<br />

begin of construction: 2007<br />

completion: 2008 / 09 / 10<br />

5 km distance to the city centre<br />

17 km distance to the airport<br />

Wien-Schwechat<br />

Ü www.viertel-zwei.at<br />

Ü www.diva.at<br />

, inside.alpine.at<br />

Award. This price is awarded annually to visionaries,<br />

owners and project developers that realise exceptional<br />

and innovative concepts and projects. The criteria<br />

evaluated by the jury are architecture, innovation,<br />

profitability, marketing and how well the real estate is<br />

rented out.<br />

on schedule desPite the econoMic crisis<br />

Despite the world-wide economic crisis there were no<br />

corrections necessary in either construction or utilization<br />

of the buildings. It will be built and rented out. The<br />

entire real estate project VIERTEL ZWEI moves on, untouched<br />

by the crisis. The office project RUND VIER has<br />

been completed already. BIZ ZWEI will be completed<br />

by the end of December 2009. Already in summer 2009<br />

the construction of 78 apartments was begun to fully<br />

utilise this area and give the district its final touch.<br />

A small decrease in demand was noted. Square-footage<br />

efficiency and cost effectiveness increasingly gain in<br />

importance. In the end however, quality will win. “We<br />

even noted this when renting out both office buildings.<br />

We are close to signing some of the contracts” said Mag.<br />

Sabine Ullrich, MD of IC Projektentwicklung GmbH.<br />

About 92,000 m2 rentable space will be available on<br />

this land with roughly 40.000 m2 north of Krieau (a<br />

part of a Vienna municipal district). The investment<br />

sum is 300 million Euro. //

closE to thE wind<br />

A wind turbine consists of a tower, a machine house with generator and of<br />

rotor blades. A wind power station produces energy by changing the wind<br />

force into a torsional moment (turning force) acting on the rotor blades.<br />

The generator changes mechanical energy into electrical energy. The volume<br />

of energy transferred onto the rotor by the wind depends on air density,<br />

the area of the rotor blades and wind speed. Wind speed increases the<br />

energy yield almost at the power of three. The efficiency factor is between<br />

25 % and 30 %, in theory even 70 %.<br />

A certain infrastructure is necessary to set up a wind turbine. Its huge<br />

components must be brought to their final destination. The manufacturer‘<br />

logistics department takes care of that. Before a wind turbine is sold<br />

experts check out access roads in detail (particularly the radius of turns).<br />

Wind turbines are usually transported by ship when they leave the manufacturer.<br />

Transportation then continues by truck.<br />

WhAt deterMines the loCAtion oF A Wind turBine?<br />

The wind speed of a specific location is the<br />

most important criterion. There are so-called<br />

wind charts that depict the wind regime, particularly<br />

wind speed. These allow a first evaluation<br />

of the suitability of a location. Topography<br />

is the most determining factor for wind<br />

speed. The surface of the water allows high,<br />

undamped wind speeds. Topographically varied<br />

environments not only cause a lower mean<br />

wind speed but also influence wind direction.<br />

The topographical influence becomes less and<br />

less the higher one goes above ground level.<br />

Wind speed increases the most 100 metres<br />

above ground. The wind speed at the hub is<br />

gondola<br />

it contains the<br />

wind turbine‘s entire<br />

machine unit<br />

rotor Blades<br />

made of preimpregnated expoxy<br />

fibre glass/carbon fibre<br />

rotor<br />

Diameter: 90 m<br />

Weight: 36 t<br />

tower<br />

Height: 100 m<br />

Weight: 255 t<br />

23<br />

the most important factor for a wind turbine.<br />

The distance to a transfer point for energy<br />

produced is another criterion for the choice of<br />

a location. Wind conditions are measured for at<br />

least a year once a location has been selected<br />

to have full data and certainty on the actual<br />

wind regime of that location.

24 // PROJECT<br />

Including<br />

five-o’clock tea<br />

DESERT GAMES A typical game of cricket lasts from four to five days -<br />

including five-o’clock tea and picnic. Fans never get bored with it. ALPINE has<br />

constructed the new cricket stadium in only 28 months.<br />

// clAUDiA lAgler<br />

S<br />

Soccer is good, cricket is<br />

better: At least this applies<br />

to Great Britain and many<br />

other Commonwealth countries.<br />

Scores of spectators are electrified<br />

with this elitist team game and its<br />

complicated rules. It is not unusual<br />

to have 50,000 or more spectators<br />

at one of the large cricket stadiums<br />

in Australia, India or Pakistan.<br />

Equipped with T-shirt, club scarf,<br />

cap and picnic basket they enthusi-<br />

astically start their club song whenever<br />

their team scored. Each team<br />

consists of eleven players - the only<br />

parallel to soccer.<br />

Plait-Patterned juMPers<br />

and fast Balls<br />

Tradition is held high in this sport:<br />

The players wear classic attire:<br />

plait-patterned jumpers, white<br />

shirts, long white trousers and a<br />

white cap. The small ball to be hit<br />

is red, hard and very fast. A typical<br />

game lasts from four to five days.<br />

Traditionally there are five-o’clocktea<br />

breaks and the spectators are<br />

equipped for a great and long<br />

sport event, picnic basket and all.<br />

„Cricket has many social aspects.<br />

The entire family shows up, spends<br />

time together and learns for life“ Siva<br />

Nadarajah says, president of Austria<br />

Cricket Club Vienna. Nadarajah

ought his love for this sport from<br />

his home country Sri Lanka and<br />

fulfilled his life’s dream in Vienna:<br />

He founded his own cricket club,<br />

got his own stadium and excited<br />

many youngsters for this rather<br />

exotic sport on mainland Europe.<br />

Fans are excited as cricket takes<br />

long to play and never gets boring.<br />

Cricket is a team game with attack<br />

and defence clearly separated. The<br />

teams face each other either as<br />

batsmen or fielders. Such a phase<br />

in the game is called an inning.<br />

The batsmen try to score (making<br />

so-called runs) while the fielder try<br />

to dismiss the batsmen. This phase<br />

is completed when ten out of eleven<br />

batsmen have been dismissed and<br />

the teams switch roles.<br />

extensive rules<br />

While even the game‘s basic<br />

concept is hard to understand<br />

for a laymen the details sometimes<br />

even intimidate loyal fans or<br />

fanatic players (see next page for<br />

the rules of this game). Founded in<br />

1787 the noble Marylebon Cricket<br />

Club (MCC) in London supervises<br />

everything to ensure the rules are<br />

strictly followed and traditions<br />

meticulously observed. Women did<br />

not have access to cricket facilities<br />

for a long time.<br />

join the talk aBout cricket // iMPortant terMs<br />

INNINGS // A round (phase) in the game after which the batsmen and fielders change rolen<br />

RUNS // Scores obtained when the two batsmen change position<br />

WICKET // Three vertical stubs topped with bails (short wooden cross bars) merely resting<br />

on top of the stubs<br />

star in the desert<br />

BATSMEN // The two batsmen on the filed called striker and non-striker. They wear protective<br />

gear (skin guards, gloves and helmet) and a cricket bat<br />

BOWLER // A field player throwing six balls in such a way that they bounce in front of the striker<br />

PITCH // A playing field of about 20 metres in length at the end of which the two wickets are<br />

located. it is the most carefully prepared part of the playing field. its grass is cut extremely short<br />

since April 2009 dubaisports-City<br />

is the best<br />

address for cricket.<br />

Not too long ago Dubai became<br />

the Arabian area‘s best address for<br />

cricket players. The new cricket<br />

stadium was inaugurated at the end<br />

of April. It is part of the world’s largest<br />

sport centre: Dubai Sports City.<br />

As part of a joint venture with Emirates<br />

Belbadi Contracting with seat<br />

in Dubai, ALPINE Bau Deutschland<br />

constructed this cricket stadium.<br />

25

26 // PROJECT<br />

cricket stars<br />

WASIM AKRAM<br />

Pakistan<br />

Best bowler of all times<br />

SACHIN TENDULKAR<br />

India<br />

Holds the most runs ever<br />

ANDREW ‚FREDDIE‘ FLINTOFF<br />

England<br />

Excellent all-rounder<br />

DONALD BRADMAN<br />

Australia<br />

Best batsman of all times<br />

ADAM GILCHRIST<br />

Australia<br />

Celebrated wicket keeper<br />

MORE ON CRICKET ON THE INTERNET Ü<br />

Marylebon Cricket Club // www.lorDS.org<br />

International Cricket Council // www.Icc-crIckEt.com<br />

Deutscher Cricketbund // www.crIckEt.DE<br />

Austria Cricket Club Wien // www.auStrIacrIckEt.com<br />

Cricket Club Velden // www.ccv91.at<br />

30 sec. // CriCKet<br />

The reason cricket is so hard to<br />

understand to a layman is the way<br />

this game is plaid and because<br />

its has so many complicated<br />

rules. America has developed<br />

baseball from cricket with simpler<br />

rules and a simpler form of the<br />

game. The batting team has two<br />

batsmen at the playing field called<br />

pitch. They protect the wickets<br />

which the other team has to<br />

destroy with the ball to dismiss a<br />

batsman. The batsmen can score<br />

runs (points) only if they bat the<br />

ball thrown by the bowler (a player<br />

from the field team) as far away<br />

as possible to allow the batsmen<br />

to switch positions. if they manage<br />

they score a point. A batsman<br />

is dismissed and the team‘s next<br />

batsman goes onto the pitch if the<br />

ball has been brought back to the<br />

pitch before the batsmen are back<br />

in their positions. The batting<br />

team continues to bat until their<br />

last batsmen has been dismissed.<br />

At that point the teams switch<br />

their roles.

Its cross-vaulted roof style reminds<br />

of a star in the middle of the desert.<br />

Up to 25,000 spectators can watch<br />

competing teams in this modern<br />

sports facility. The roof construction<br />

protects the seating from sun<br />

and wind. The field is under the<br />

open sky. The earth for the playground<br />

has been specifically imported<br />

from Pakistan to proved the best<br />

possible conditions for the players.<br />

It‘s almost a matter of course to<br />

have a special lawn. Cricket players<br />

in no way stay behind golfers in<br />

their care for the lawn.<br />

Dubai Sports City (located right in<br />

the middle of the desert) will hold<br />

even more facilities, e.g. a shopping<br />

mall and a multi-function stadium<br />

for soccer, rugby and athletics.<br />

a feel for the Ball and a<br />

fantastic catcher<br />

„The different versatilities required is<br />

what makes cricket so fascinating“<br />

OPeNiNg MATcH 22/04/2009<br />

171 : 168<br />

PAKISTAN : AUSTRALIA<br />

says Michael Tschernitz, president<br />

of the Cricket Club Velden, founded<br />

in 1991: „You must have a feel for the<br />

ball, be a fantastic catcher, have a<br />

good eye, a fast reaction, an excellent<br />

condition and mental strength“. It is<br />

a fast and exciting game despite its<br />

length. Nadarajah points out that<br />

most of the time the entire family<br />

shows up. He says that in most<br />

Muslim areas women are welcome<br />

in the stadiums: „Cricket is for cosmopolitan<br />

people“.<br />

Games played according to the<br />

classic rules are called tests. They<br />

last for several days and most of the<br />

time are part of a series of games.<br />

Only a few national teams have the<br />

permission to play tests. The strongest<br />

teams world-wide come from<br />

Australia, South Africa, India, Sri<br />

Lanka, England and Pakistan.<br />

Cricket has not remained the same<br />

despite the love for tradition. One-<br />

Day-Internationals increasingly<br />

gained importance for several deca-<br />

des. The modern form of cricket is<br />

considerably faster - a concession<br />

to TV. The classic white dropped<br />

out from these games. Teams are<br />

dressed in their national colours<br />

and the ball is white. Traditionalists<br />

the dubai stadium’s<br />

cross-vaulted roof style<br />

reminds of a star in the<br />

middle of the desert.<br />

respond to these changes with the<br />

cry „It’s not Cricket.“ – which in<br />

Great Britain is synonymous with:<br />

That’s improper. //<br />

27

28 // MARKET<br />

SISSI, HEIDI GABI<br />

go on a joUrney<br />

LOGISTICS It sounds like three girls making a pleasure trip but actually is a logistic<br />

master piece. Sissi, Heidi, Gabi I and II are quite heavy-weight ladies – each of them weighs<br />

about 3,000 tons and with back-up is more than 400 m in length.<br />

// iNeS ScHMieDMAier<br />

ese heavy-duty workers<br />

are tunnel boring<br />

T machines (TBM) with<br />

an impressive propelling force of<br />

27.500 kN and a cutter head power<br />

of 3,500 kW. They press this force<br />

against the tunnel face and cut out<br />

pieces of mountain rock the size<br />

&<br />

of a breakfast plate. However, the<br />

steel colossus first need to get to the<br />

Gotthard tunnel before they can<br />

begin working.<br />

From the very beginning, the procurement<br />

process is a central part<br />

in all work procedures. An order<br />

is placed with the manufacturer<br />

of tunnel boring machines as soon<br />

as a construction company wins a<br />

tender and has it finally confirmed.<br />

Both, construction company and<br />

TBM manufacturer are pressed for<br />

time. The time between the placement<br />

of a job and TBM delivery

dates are increasingly becoming<br />

shorter. The planning phases are<br />

long - and each machine is one of<br />

its kind.<br />

The machine is to leave the factory<br />

as soon as possible as the storage<br />

costs are extremely high. The<br />

machine is almost completely assembled<br />

(95 %) when the customer<br />

performs the factory tests and accepts<br />

the machine. All electro-mechanical<br />

and hydraulic functions<br />

work. The only thing that cannot be<br />

tested is actual drilling. The technical<br />

acceptance is the first hurdle<br />

the manufacturer has to master and<br />

is part of a contractually regulated<br />

procedure. In most cases a contract<br />

is fulfilled only once the tunnel<br />

boring machine arrived at its final<br />

destination, has been completely<br />

assembled and performed the first<br />

few metres of tunnelling.<br />

transPortation is<br />

taken into account in<br />

construction<br />

Construction must already take into<br />

account that the machine will be<br />

assembled, disassembled and reassembled<br />

at its final destination. “30<br />

years of experience play their part in<br />

handling logistics” says Achim Kühn<br />

from the company Herrenknecht<br />

AG in the city of Schwanau (Baden-<br />

Württemberg). About half of all<br />

tunnel boring machines produced<br />

world-wide are manufactured by<br />

this German company.<br />

The logistics part is enormous:<br />

There are about 90,000 individual<br />

parts to a machine. As few components<br />

as possible are disassembled<br />

and the modules are kept as large<br />

as possible for transportation. They<br />

all must arrive at the final destination<br />

according to an exact schedule.<br />

“The hub of it all is project management”<br />

Achim Kühn points out. The<br />

precious goods are protected from<br />

dust and dirt by custom-developed<br />

transportation boxes.<br />

98 % of transportation occur on<br />

water, only 2 % on land. The first<br />

leg from the factory in Schwanau to<br />

the harbour at the city of Kehl (at<br />

the river Rhine) is partially handled<br />

with extra-wide and extra-long<br />

trailers. This is where the parts are<br />

loaded onto ships and shipped via<br />

inland-water-transport routes or<br />

via Rotterdam and the open see.<br />

at the Base of the hiMalaYa<br />

A considerably tougher challenge<br />

is a transportation to India. This is<br />

where ALPINE (as part of a consortium)<br />

constructs an 11.3 km-long<br />

headrace tunnel for a hydropower<br />

station in Tapovan-Vishnugad.<br />

The main bearing of a tunnel boring<br />

machines weighs 85 tons and must<br />

be shipped in two parts as streets<br />

do not allow a weight of more than<br />

60 tons. Not all machine parts must<br />

be shipped to India as the less sensitive<br />

parts are manufactured in India<br />

according to German plans and<br />

subjected to the same tests.<br />

First the containers or transport<br />

boxes arrive at one of the Mumbai<br />

harbours. One harbour only handles<br />

containers and the other only<br />

general cargo. The handling of containers<br />

is faster than that of general<br />

cargo. The goods belonging together<br />

however must be shipped<br />

together despite such differences.<br />

Custom clearance can take between<br />

4 to 6 weeks due to Indian bureaucracy.<br />

“Key to it all is the cooperation<br />

with the right shipper” Paul Bargmann<br />

points out. He is responsible<br />

for the preparation of all machines<br />

necessary for tunnelling.<br />

700 kM in 8 to 10 daYs<br />

Next comes the heavy-load transportation<br />

on the motorway. It takes<br />

from 8 to 10 days to cover the 700<br />

km from Mumbai to Rishikesh at<br />

the base of the mountains. In India<br />

a centre rail, if there at all, serves<br />

only as a rough guideline. Vehicles<br />

and bicycles are tightly packed<br />

on the roads and cows have to be<br />

avoided. The challenge becomes a<br />

real challenge once the base of the<br />

maintains has been reached. The<br />

monsoon may well sweep away a<br />

road or giant rocks may block the<br />

roads that usually are in bad repair<br />

or not solidified at all and soaked.<br />

High humidity may creep into container<br />

and damage machine parts.<br />

Instructing experts and handling<br />

insurance claims is part of the daily<br />

routine once a damage occurred.<br />

There is little space at a tunnel construction<br />

site and all parts must be<br />

delivered in an exact sequence -<br />

as must all material necessary for<br />

construction. A fourwheeler with<br />

a payload of 8 - 10 tons requires<br />

about a day from the storage place<br />

on the plains to the construction<br />

site in about 2,000 m above sea<br />

level. A heavy-goods truck takes<br />

much longer. “Once we even have<br />

lost a container on its way up” Paul<br />

Bargmann tell us. He adds “Once we<br />

had sent a search party we found it in<br />

the middle of the road”. Flat concrete<br />

floors usually exist for the assembly<br />

of a TBM. In this location the work<br />

has to be done on soft and muddy<br />

ground.<br />

However, this cannot unnerve Mr.<br />

Bargmann (in business since 1972)<br />

or his Indian customer. A former<br />

colleague once stated: “We have<br />

deadlines. The Indians have time.” //<br />

Ü www.herrenknecht.de<br />

Ü www.alptransit.ch<br />

29<br />

A tunnelling<br />

construction site<br />

offers very little<br />

space – meeting<br />

exactly defined<br />

delivery schedules<br />

is essential.

30 // MARKET<br />

BalKaN

GO EAST ‘Balkan Fever’ does not only refer to the identically named<br />

cultural festival in Vienna but also is the place-to-be for the ‘young and wild’<br />

of the construction industry.<br />

// iNeS ScHMieDMAier<br />

U<br />

ntil the end of the eighties it was desirable to<br />

earn one‘s wings somewhere in Europe. Those<br />

who wanted to prove themselves at the end<br />

of the nineties subscribed to the creed ‘Go East’ and<br />

looked for adventure in the Balkan.<br />

However the geographic meaning of the term ‘Balkan’<br />

and the national self-image of the countries concerned<br />

is as diverse as the cultures on the Balkan Peninsula.<br />

The Balkan region does however include the former<br />

states of Yugoslavia, Albania, Bulgaria, Greece and the<br />

European part of Turkey in addition to Slovenia.<br />

ALPINE takes part in many projects in the Balkans as<br />

the traffic and energy infrastructure of that region is<br />

developed intensively. Qualified personnel is a must to<br />

meet the demanding technical requirements and guarantee<br />

a timely completion of all buildings at the very<br />

highest quality standards.<br />

What is needed most are executives that can be sent<br />

into an area to build up their own team wherever they<br />

are: so-called Expatriates. However, how do you find<br />

the right candidates willing to work for years at a construction<br />

site at sometimes remote locations in the Balkans?<br />

Little social contacts compound a missing infrastructure,<br />

language difficulties and cultural differences.<br />

cosMoPolitan and Personal resPonsiBilitY<br />

Jivka Atanassova is responsible for recruiting at ALPINE<br />

with focus on South-East Europe. She’s always looking<br />

for employees at construction sites abroad who first<br />

and foremost meet one criterion: cosmopolitan.<br />

All previous experience has to be scraped when starting<br />

in a new country as one’s general experience is viewed<br />

completely differently. But experience is an important<br />

factor too. The more experience one has abroad the eas-<br />

ier it is to find one’s footing in a new cultural environment,<br />

the Bulgarian-born recruiter points out.<br />

Executives face the challenge to personally be responsible<br />

to achieve the objective: to complete the construction<br />

site successfully far away from home. Decisions<br />

have to be made and structures have to be built.<br />

The requirements for both have one thing in common:<br />

They are definitely different from home!<br />

It is not enough to find your way in the host country’s<br />

culture, customs, traditions and its way of life. The different<br />

attitudes regarding time and deadlines have to<br />

be taken into account as well. “It is not common in the<br />

Balkans to plan time and use schedules. It is common to let<br />

things happen” Atanassova tells us. While West Europe<br />

says ‘time is money’ the Balkan Peninsula says ‘time is<br />

free and we have plenty thereof’. The cultures in South-<br />

East Europe focus on relations and are very hospitable.<br />

It is a must to accept invitations to dinners (usually<br />

with opulently filled plates) as they are considered confidence-building<br />

affairs.<br />

60 executives wanted<br />

Peter Gfrerer is another expert when it comes to recruiting<br />

personnel for mega construction sites. He<br />

heads the department of hydropower station engineering<br />

in Tsankov Kamak, located in the south-east part<br />

of Bulgaria. A hydropower station is to be constructed<br />

at the river Vacha, located in the mountainous region<br />

called Rhodopen. ALPINE has a contract to construct a<br />

125 m high and 457 m long arch dam, extensively seal<br />

off the intake structure and build a power house.<br />

About 1,500 people simultaneously work at this construction<br />

site, 1,200 of them are ALPINE employees and<br />

the remaining 300 are composed of subcontractors,<br />

clients and local building inspectors.<br />

31<br />

“To be able to<br />

demonstrate<br />

their ability on<br />

a daily basis,<br />

skilled workers<br />

sent abroad must<br />

be independent,<br />

be able to assert<br />

themselves yet<br />

be highly able to<br />

adjust and come<br />

with abundant<br />

dose of self assurance.”<br />

Jivka Atanassova<br />

ALPINE Recruiting<br />

South-East Europe

32 // MARKET<br />

“Ideally the<br />

team stays at<br />

the construction<br />

site until completion<br />

– this<br />

is particularly<br />

important for<br />

the project<br />

manager.”<br />

Peter gfrerer<br />

At the beginning of a project this size 60 expatriates<br />

from Austria and Germany are needed as project managers,<br />

section construction managers, foremen, machine<br />

engineers, machine foremen and so-called assistant<br />

managers (mostly metalworker).<br />

word of Mouth is excellent ProMotion<br />

When a new area of operation is being developed an<br />

external team of consultants searches for the fitting<br />

personnel meeting various requirements. An expert<br />

team might already exist if a similar project with similar<br />

conditions has just been completed. Quite often executives<br />

bring in their tried and tested crew. “Word of<br />

mouth is an excellent means to get the right people to the<br />

right place - the network of experts in this highly specialized<br />

field is small - one knows the other” Peter Gfrerer<br />

said. Classic methods like advertising and continuous<br />

contact with Technical Universities also help to find<br />

employees. Educational institutions are also contacted<br />

at the location of the construction site. The ALPINE HR<br />

department actively promotes the cooperation already<br />

existing with the Technical University in Sofia. An employee<br />

from Bulgaria (a graduate of the university of<br />

applied sciences in Varna) brought in his fellow student.<br />

Now he too found work at the power station construction<br />

site. Then there are ‘modern nomads’ working<br />

on construction sites around the world. A drawback<br />

is that these employees quite often lack a bond with<br />

any particular company. When even little difficulties<br />

arise they quit.<br />

froM start to finish<br />

“Ideally the team stays at the construction site until completion<br />

- this is particularly important for the project manager”<br />

Peter Gfrerer said. “Often there are teething problems<br />

while a team forms. This lasts until each found his<br />

place” Gfrerer continues, “however, this phase is over<br />

and now the core team works together well for two and a<br />

half year”.<br />

Sometimes the construction period is hard to estimate.<br />

The hydropower station was estimated to be completed<br />

in 48 months. By now this has stretched out to 72<br />