CPT International 02/2017

The leading technical journal for the global foundry industry – Das führende Fachmagazin für die weltweite Gießerei-Industrie

The leading technical journal for the

global foundry industry – Das führende Fachmagazin für die

weltweite Gießerei-Industrie

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SIMULATION<br />

Lu Baosheng, Changchun, China<br />

Manufacturability of a cylinder<br />

block sand core<br />

Quality sand cores are a natural requirement for most high integrity castings. Just as for the castings,<br />

the challenges are related to technical, environmental and cost aspects. One key factor for a<br />

robust core production is manufacturability: the reliability of production considering the given facility<br />

conditions. For FAW Foundry, core process simulation using MAGMA C+M is an important<br />

tool to establish a robust state-of-the art production of lightweight automotive cylinder blocks<br />

Sand core production is as complex<br />

and demanding as the manufacture of<br />

metal castings. A robust and high quality<br />

production means efficient development,<br />

reduced energy consumption<br />

and waste, and foremost a guaranteed<br />

consistent quality. A typical example<br />

for these diverse targets is a core for an<br />

automotive cylinder block being produced<br />

for a renowned and internationally<br />

active automobile company.<br />

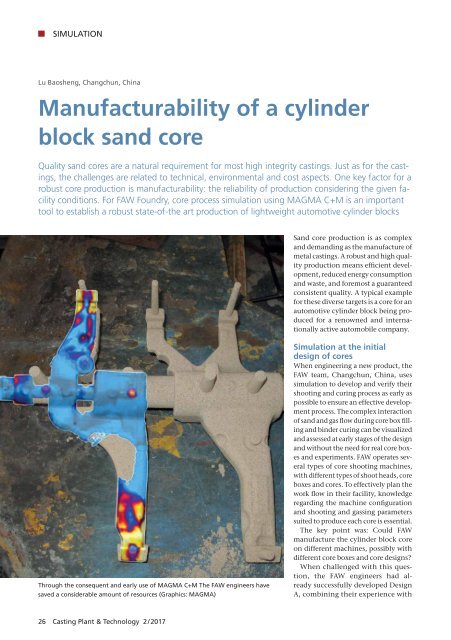

Through the consequent and early use of MAGMA C+M The FAW engineers have<br />

saved a considerable amount of resources (Graphics: MAGMA)<br />

Simulation at the initial<br />

design of cores<br />

When engineering a new product, the<br />

FAW team, Changchun, China, uses<br />

simulation to develop and verify their<br />

shooting and curing process as early as<br />

possible to ensure an effective development<br />

process. The complex interaction<br />

of sand and gas flow during core box filling<br />

and binder curing can be visualized<br />

and assessed at early stages of the design<br />

and without the need for real core boxes<br />

and experiments. FAW operates several<br />

types of core shooting machines,<br />

with different types of shoot heads, core<br />

boxes and cores. To effectively plan the<br />

work flow in their facility, knowledge<br />

regarding the machine configuration<br />

and shooting and gassing parameters<br />

suited to produce each core is essential.<br />

The key point was: Could FAW<br />

manu facture the cylinder block core<br />

on different machines, possibly with<br />

different core boxes and core designs?<br />

When challenged with this question,<br />

the FAW engineers had already<br />

successfully developed Design<br />

A, combining their experience with<br />

26 Casting Plant & Technology 2 / <strong>2017</strong>