CPT International 01/2018

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRESSURE DIE CASTING<br />

Robert Piterek, German Foundry Association, Düsseldorf<br />

Globalization in Swabian<br />

60 years after Föhl was founded, looking back is much less interesting than looking ahead: the<br />

zinc and plastic caster from Rudersberg near Stuttgart is preparing itself for the future with re-<br />

nese<br />

market<br />

die-casting foundry”), the consolidation<br />

of important processes, further<br />

work on establishing a corporate culture,<br />

and the professionalization of<br />

further education and training.<br />

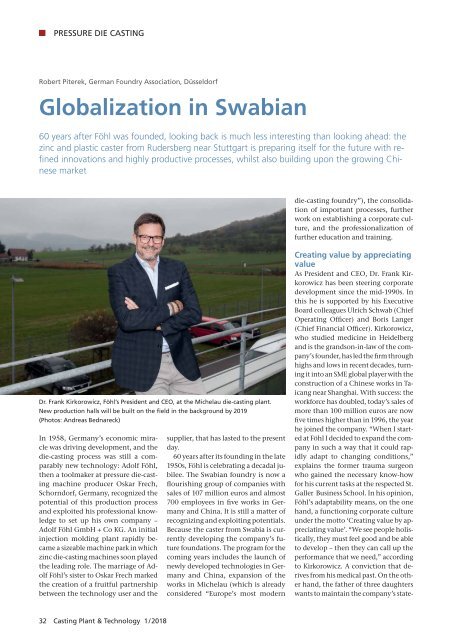

Dr. Frank Kirkorowicz, Föhl’s President and CEO, at the Michelau die-casting plant.<br />

<br />

(Photos: Andreas Bednareck)<br />

In 1958, Germany’s economic miracle<br />

was driving development, and the<br />

die-casting process was still a comparably<br />

new technology: Adolf Föhl,<br />

then a toolmaker at pressure die-casting<br />

machine producer Oskar Frech,<br />

Schorndorf, Germany, recognized the<br />

potential of this production process<br />

and exploited his professional knowledge<br />

to set up his own company –<br />

Adolf Föhl GmbH + Co KG. An initial<br />

injection molding plant rapidly became<br />

a sizeable machine park in which<br />

zinc die-casting machines soon played<br />

the leading role. The marriage of Adolf<br />

Föhl’s sister to Oskar Frech marked<br />

the creation of a fruitful partnership<br />

between the technology user and the<br />

supplier, that has lasted to the present<br />

day.<br />

60 years after its founding in the late<br />

1950s, Föhl is celebrating a decadal jubilee.<br />

The Swabian foundry is now a<br />

flourishing group of companies with<br />

sales of 107 million euros and almost<br />

700 employees in five works in Germany<br />

and China. It is still a matter of<br />

recognizing and exploiting potentials.<br />

Because the caster from Swabia is currently<br />

developing the company’s future<br />

foundations. The program for the<br />

coming years includes the launch of<br />

newly developed technologies in Germany<br />

and China, expansion of the<br />

works in Michelau (which is already<br />

considered “Europe’s most modern<br />

Creating value by appreciating<br />

value<br />

As President and CEO, Dr. Frank Kirkorowicz<br />

has been steering corporate<br />

development since the mid-1990s. In<br />

this he is supported by his Executive<br />

Board colleagues Ulrich Schwab (Chief<br />

Operating Officer) and Boris Langer<br />

(Chief Financial Officer). Kirkorowicz,<br />

who studied medicine in Heidelberg<br />

and is the grandson-in-law of the company’s<br />

founder, has led the firm through<br />

highs and lows in recent decades, turning<br />

it into an SME global player with the<br />

construction of a Chinese works in Taicang<br />

near Shanghai. With success: the<br />

workforce has doubled, today’s sales of<br />

more than 100 million euros are now<br />

five times higher than in 1996, the year<br />

he joined the company. “When I started<br />

at Föhl I decided to expand the company<br />

in such a way that it could rapidly<br />

adapt to changing conditions,”<br />

explains the former trauma surgeon<br />

who gained the necessary know-how<br />

for his current tasks at the respected St.<br />

Galler Business School. In his opinion,<br />

Föhl’s adaptability means, on the one<br />

hand, a functioning corporate culture<br />

under the motto ‘Creating value by appreciating<br />

value’. “We see people holistically,<br />

they must feel good and be able<br />

to develop – then they can call up the<br />

performance that we need,” according<br />

to Kirkorowicz. A conviction that derives<br />

from his medical past. On the other<br />

hand, the father of three daughters<br />

wants to maintain the company’s state-<br />

32 Casting Plant & Technology 1 / 2<strong>01</strong>8