SPRING 2018

Distributor's Link Magazine Spring 2018 / Vol 41 No2

Distributor's Link Magazine Spring 2018 / Vol 41 No2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

116<br />

THE DISTRIBUTOR’S LINK<br />

ANTHONY Di MAIO STRUCTURAL TYPE BLIND RIVETS from page 34<br />

Multi-Grip is another advantage to the Monobolt and<br />

the Interlock Structural Blind rivets. One size rivet will<br />

accommodate many work thicknesses forces exist. Both<br />

having a locked portion of the mandrel in the set rivet<br />

body, avoiding the need to purchase many length rivets.<br />

This special nosepiece has a raised ring around the<br />

hole of the nosepiece that the mandrel is inserted into to<br />

set the rivet. The raised ring engages the locking shirt of<br />

the mandrel and flairs out the skirt into the body of the<br />

structural blind rivet. The locking skirt is forced into the<br />

inside wall of the rivet body as the setting tool pulls the<br />

There are 4 sizes of Monobolts and Interlocks: mandrel and when the tensile strength of the mandrel<br />

RIVET NO. GRIP RANGE<br />

is reached, the mandrel breaks. The mandrel breaks at<br />

64 .062-.250<br />

the pre-determined tensile value and at a pre-determined<br />

67 .214-.437<br />

breaking point of the mandrel.<br />

86 .080-.375<br />

The pre-determined breaking point, or breaking<br />

810 .350-.625<br />

position of the mandrel, is a groove that has been formed<br />

There are 2 diameters the Monobolt and Interlock is<br />

manufactured to, and that is “6”= 3/16 (.187) Diameter<br />

and “8” = 1/4 Diameter (.250). If you set any one of the<br />

above structural blind rivets and set it in the following<br />

ways:- one with no work thickness and one at maximum<br />

grip range, you will see that the mandrel material inside<br />

the body of the set rivet, is at the same position in both<br />

rivet bodies. No matter what work thickness (within the<br />

grip range of the rivet) you are setting this rivet in, the<br />

mandrel locking feature will lock the mandrel in the same<br />

position and that is flush with the flange. This happens<br />

for the following reason.<br />

into the mandrel diameter at a depth to determine the<br />

tensile strength of the mandrel.<br />

No matter what the work thickness is, the locking<br />

skirt will travel to the special nosepiece. The nosepiece<br />

will flair out the locking skirt into the inside wall of<br />

the rivet body and the mandrel will break at the predetermined<br />

tensile groove.<br />

The multiple grooves on the mandrel shank, are<br />

there to prevent the pulling jaws of the setting tool from<br />

slipping. Some setting tools use two piece pulling jaws<br />

and other tools use a three piece pulling jaws. In either<br />

case, the theory is the same. The pulling jaws have<br />

grooves that contact the grooves of the shank diameter<br />

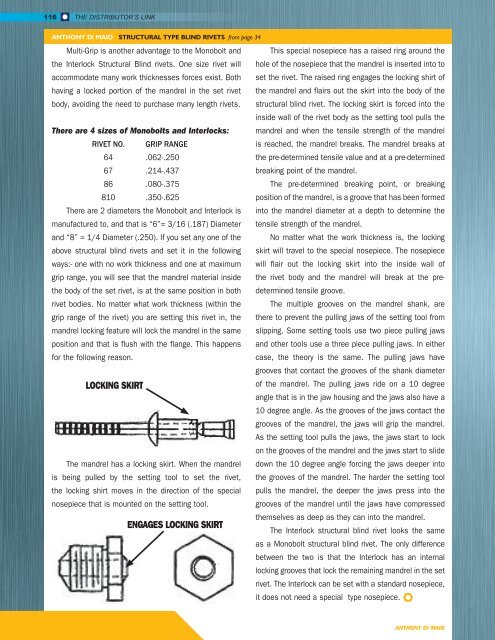

LOCKING SKIRT<br />

The mandrel has a locking skirt. When the mandrel<br />

is being pulled by the setting tool to set the rivet,<br />

the locking shirt moves in the direction of the special<br />

nosepiece that is mounted on the setting tool.<br />

ENGAGES LOCKING SKIRT<br />

of the mandrel. The pulling jaws ride on a 10 degree<br />

angle that is in the jaw housing and the jaws also have a<br />

10 degree angle. As the grooves of the jaws contact the<br />

grooves of the mandrel, the jaws will grip the mandrel.<br />

As the setting tool pulls the jaws, the jaws start to lock<br />

on the grooves of the mandrel and the jaws start to slide<br />

down the 10 degree angle forcing the jaws deeper into<br />

the grooves of the mandrel. The harder the setting tool<br />

pulls the mandrel, the deeper the jaws press into the<br />

grooves of the mandrel until the jaws have compressed<br />

themselves as deep as they can into the mandrel.<br />

The Interlock structural blind rivet looks the same<br />

as a Monobolt structural blind rivet. The only difference<br />

between the two is that the Interlock has an internal<br />

locking grooves that lock the remaining mandrel in the set<br />

rivet. The Interlock can be set with a standard nosepiece,<br />

it does not need a special type nosepiece.<br />

ANTHONY Di MAIO