ETX-10829_Etex-AR2017_WEB_2018_DEF2 (2)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.3<br />

About <strong>Etex</strong><br />

Our three-pillar agenda<br />

<strong>Etex</strong> Annual Report 2017<br />

About <strong>Etex</strong><br />

Our three-pillar agenda<br />

Profitable<br />

growth<br />

Operational<br />

excellence<br />

Capitalising on the global structure<br />

introduced in 2016, our divisions target<br />

well-defined business segments to<br />

capture growth pockets and meet<br />

specific challenges.<br />

In 2017, we integrated our Latin America<br />

business into this structure. Consequently,<br />

we sold Chilean brick company Industrias<br />

Princesa, whose activities fall outside our<br />

core business.<br />

From producing building materials<br />

to providing building solutions<br />

To grow our business, we have an<br />

expanding merger and acquisition radar<br />

in place. In 2017, this was evident in our<br />

acquisition of Spanish plasterboard<br />

company Pladur.<br />

Furthermore, thanks to increased market<br />

intimacy, we aim to bring value-driven<br />

propositions to market. Our joint venture<br />

with Chilean composite wood panel<br />

producer Arauco is a significant first step in<br />

this direction. We also launched affordable<br />

housing initiatives in Nigeria and Peru.<br />

An innovation-forward approach<br />

In 2017, our innovation and technical<br />

expertise increased margins slightly more<br />

than associated overheads. We also<br />

developed a substantial pipeline of new<br />

products and solutions.<br />

A complete review of our innovation<br />

processes and metrics enables our three<br />

Innovation and Technology Centres (ITCs)<br />

to collaborate more closely without<br />

boundaries. The ITC organisations also<br />

ensure that innovation activities are<br />

developed alongside the business.<br />

To maintain close relationships with<br />

customers, these centres host open<br />

innovation days. Customers visit our<br />

centres, see and test new products and give<br />

their all-important feedback. This ensures<br />

we remain competitive and that our efforts<br />

target market and customer needs.<br />

Streamlined footprint<br />

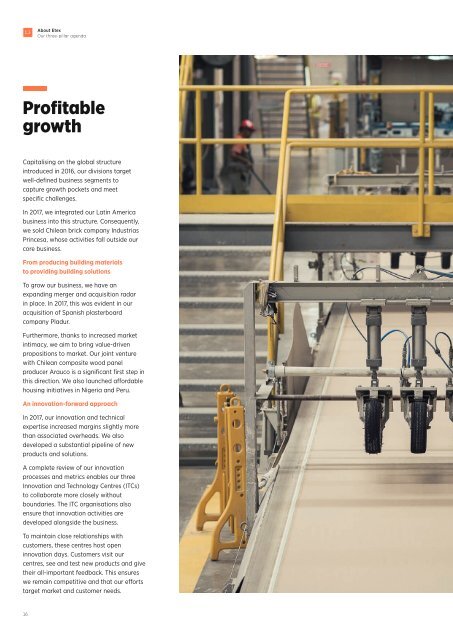

Increasing productivity and improving<br />

existing equipment and machinery at<br />

our plants is crucial. Prior investments<br />

made in 2015 and 2016 supported growth<br />

throughout 2017 without exceptional<br />

capital expenditure. In addition, enhanced<br />

communication and collaboration between<br />

our engineering, operations and purchasing<br />

organisations has led to more effective<br />

project management in terms of timing,<br />

cost and deliverables.<br />

Furthermore, our new Cedral line for<br />

fibre cement siding in Lithuania is fully<br />

operational. We also made smaller,<br />

targeted investments, building capacity to<br />

meet market needs more quickly. In total,<br />

11 major projects will come online in <strong>2018</strong>.<br />

In Germany, we reassessed and<br />

consolidated our production footprint.<br />

We closed our facility in Heidelberg.<br />

We also sold our clay façade panel<br />

factory in Weroth, which is outside our<br />

portfolio scope.<br />

Buy for best value<br />

The integrated purchasing organisation set<br />

up in 2016 paid off in 2017. Harnessing the<br />

group’s purchasing power, we continue to<br />

take advantage of the many opportunities<br />

to increase overall cost savings across the<br />

business to deliver benefits to all our local<br />

companies. We will continue to build upon<br />

this approach in <strong>2018</strong> as we seek not just<br />

to buy better, but also to spend smarter in<br />

terms of total cost of ownership.<br />

Enhanced shared services<br />

As they are further integrated across our<br />

activities, our shared services centres<br />

continue to enhance transactional support<br />

to the business. By introducing more<br />

automated and end-to-end processes,<br />

these centres are on course to further<br />

reduce costs, engage teams and improve<br />

customer satisfaction.<br />

BIM for better buildings<br />

We made headway integrating Building<br />

Information Management (BIM) technology<br />

into our projects. Using BIM helps boost<br />

demand for our products, increase<br />

efficiency and promote collaboration with<br />

customers. We aim to become an industry<br />

leader in using this digital tool.<br />

PPOur industrial facilities are always striving<br />

to do more with less. We continue to invest in<br />

increasing productivity and improving existing<br />

equipment and machinery at our plants.<br />

16 17