CPT International 02/2018

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FETTLING & FINISHING<br />

Matthias Schweizer, Filderstadt<br />

Perfect grinding for aluminum<br />

framing components<br />

A tier-1 die-casting supplier in Slovakia manufactures complex aluminum framing components<br />

for premium vehicles. A state-of-the-art system delivered by automation specialist SHL AG,<br />

headquartered in Böttingen, Germany, provides these components with perfect grinding. Eight<br />

robots feed the parts into each processing station and then deposit them for further processing<br />

<br />

of quality and the system operates with complete reliability. SHL has delivered an entire manufacturing<br />

line for handling, loading, processing, unloading, and extraction processes<br />

With the construction of a new hall,<br />

the supplier also put its production to<br />

the test in order to optimize processes.<br />

In conjunction with this, the company<br />

was searching for a solution for the automated<br />

grinding of body panels that<br />

have complex geometrics, known as<br />

suspension seatings. The requirements<br />

were clearly defined: the parts needed<br />

to be free from burrs and fire cracks in<br />

order to then be able to adhere them<br />

without issue. On top of this, the system<br />

needed to operate reliably with a high<br />

output: a pair of left and right suspension<br />

seatings needs to be finish-ground<br />

every 140 seconds (Figure 1).<br />

One of the largest systems in<br />

the company’s history<br />

A total of eight competitors took part<br />

in the call for tenders. Ultimately, SHL<br />

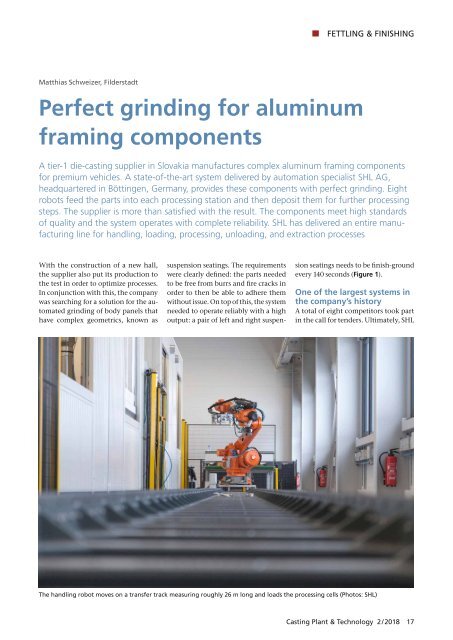

The handling robot moves on a transfer track measuring roughly 26 m long and loads the processing cells (Photos: SHL)<br />

Casting Plant & Technology 2 / <strong>2018</strong> 17