CPT International 02/2018

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

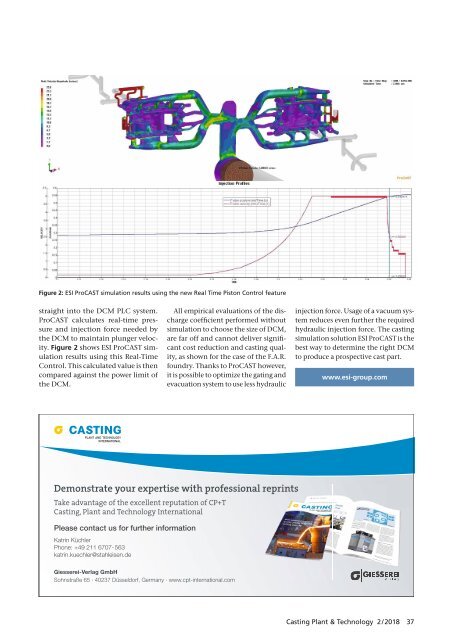

Figure 2: ESI ProCAST simulation results using the new Real Time Piston Control feature<br />

straight into the DCM PLC system.<br />

ProCAST calculates real-time pressure<br />

and injection force needed by<br />

the DCM to maintain plunger velocity.<br />

Figure 2 shows ESI ProCAST simulation<br />

results using this Real-Time<br />

Control. This calculated value is then<br />

compared against the power limit of<br />

the DCM.<br />

All empirical evaluations of the discharge<br />

coefficient performed without<br />

simulation to choose the size of DCM,<br />

are far off and cannot deliver significant<br />

cost reduction and casting quality,<br />

as shown for the case of the F.A.R.<br />

foundry. Thanks to ProCAST however,<br />

it is possible to optimize the gating and<br />

evacuation system to use less hydraulic<br />

injection force. Usage of a vacuum system<br />

reduces even further the required<br />

hydraulic injection force. The casting<br />

simulation solution ESI ProCAST is the<br />

best way to determine the right DCM<br />

to produce a prospective cast part.<br />

www.esi-group.com<br />

Demonstrate your expertise with professional reprints<br />

Take advantage of the excellent reputation of CP+T<br />

Casting, Plant and Technology <strong>International</strong><br />

Please contact us for further information<br />

Katrin Küchler<br />

Phone: +49 211 6707- 563<br />

katrin.kuechler@stahleisen.de<br />

Giesserei-Verlag GmbH<br />

Sohnstraße 65 · 4<strong>02</strong>37 Düsseldorf, Germany · www.cpt-international.com<br />

Casting Plant & Technology 2 / <strong>2018</strong> 37