SUMMER 2018

Distributor's Link Magazine Summer 2018 / Vol 41 No3

Distributor's Link Magazine Summer 2018 / Vol 41 No3

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

176<br />

THE DISTRIBUTOR’S LINK<br />

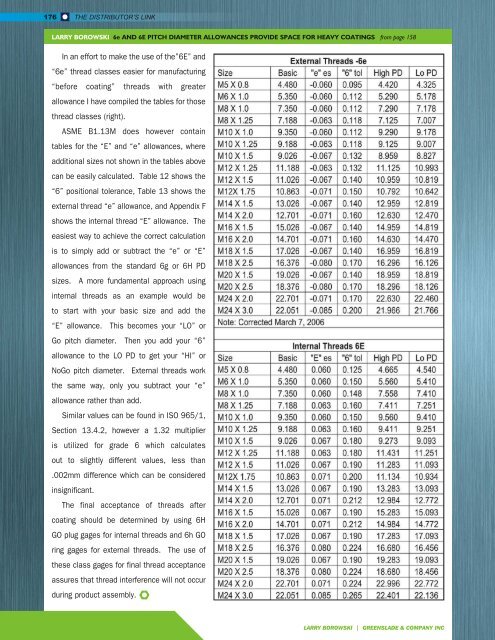

LARRY BOROWSKI 6e AND 6E PITCH DIAMETER ALLOWANCES PROVIDE SPACE FOR HEAVY COATINGS from page 158<br />

In an effort to make the use of the”6E” and<br />

“6e” thread classes easier for manufacturing<br />

“before coating” threads with greater<br />

allowance I have compiled the tables for those<br />

thread classes (right).<br />

ASME B1.13M does however contain<br />

tables for the “E” and “e” allowances, where<br />

additional sizes not shown in the tables above<br />

can be easily calculated. Table 12 shows the<br />

“6” positional tolerance, Table 13 shows the<br />

external thread “e” allowance, and Appendix F<br />

shows the internal thread “E” allowance. The<br />

easiest way to achieve the correct calculation<br />

is to simply add or subtract the “e” or “E”<br />

allowances from the standard 6g or 6H PD<br />

sizes. A more fundamental approach using<br />

internal threads as an example would be<br />

to start with your basic size and add the<br />

“E” allowance. This becomes your “LO” or<br />

Go pitch diameter. Then you add your “6”<br />

allowance to the LO PD to get your “HI” or<br />

NoGo pitch diameter. External threads work<br />

the same way, only you subtract your “e”<br />

allowance rather than add.<br />

Similar values can be found in ISO 965/1,<br />

Section 13.4.2, however a 1.32 multiplier<br />

is utilized for grade 6 which calculates<br />

out to slightly different values, less than<br />

.002mm difference which can be considered<br />

insignificant.<br />

The final acceptance of threads after<br />

coating should be determined by using 6H<br />

GO plug gages for internal threads and 6h GO<br />

ring gages for external threads. The use of<br />

these class gages for final thread acceptance<br />

assures that thread interference will not occur<br />

during product assembly.<br />

LARRY BOROWSKI | GREENSLADE & COMPANY INC