Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

19 Emission control Klarius Products<br />

EVOLUTION<br />

for modern exhaust systems<br />

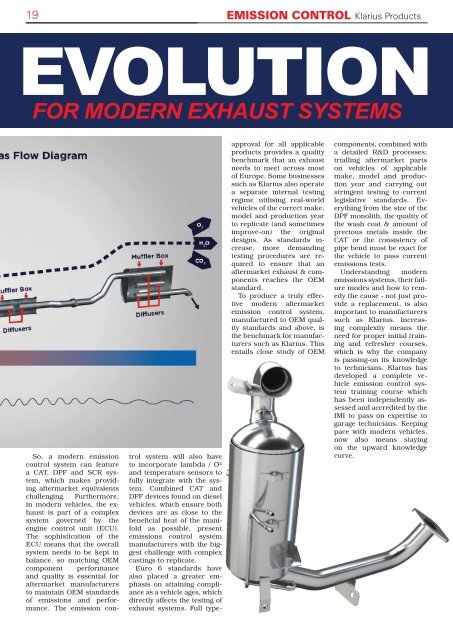

So, a modern emission<br />

control system can feature<br />

a CAT, DPF and SCR system,<br />

which makes providing<br />

aftermarket equivalents<br />

challenging. Furthermore,<br />

in modern vehicles, the exhaust<br />

is part of a complex<br />

system governed by the<br />

engine control unit (ECU).<br />

<strong>The</strong> sophistication of the<br />

ECU means that the overall<br />

system needs to be kept in<br />

balance, so matching OEM<br />

component performance<br />

and quality is essential for<br />

aftermarket manufacturers<br />

to maintain OEM standards<br />

of emissions and performance.<br />

<strong>The</strong> emission control<br />

system will also have<br />

to incorporate lambda / O²<br />

and temperature sensors to<br />

fully integrate with the system.<br />

Combined CAT and<br />

DPF devices found on diesel<br />

vehicles, which ensure both<br />

devices are as close to the<br />

beneficial heat of the manifold<br />

as possible, present<br />

emissions control system<br />

manufacturers with the biggest<br />

challenge with complex<br />

castings to replicate.<br />

Euro 6 standards have<br />

also placed a greater emphasis<br />

on attaining compliance<br />

as a vehicle ages, which<br />

directly affects the testing of<br />

exhaust systems. Full typeapproval<br />

for all applicable<br />

products provides a quality<br />

benchmark that an exhaust<br />

needs to meet across most<br />

of Europe. Some businesses<br />

such as Klarius also operate<br />

a separate internal testing<br />

regime utilising real-world<br />

vehicles of the correct make,<br />

model and production year<br />

to replicate (and sometimes<br />

improve-on) the original<br />

designs. As standards increase,<br />

more demanding<br />

testing procedures are required<br />

to ensure that an<br />

aftermarket exhaust & components<br />

reaches the OEM<br />

standard.<br />

To produce a truly effective<br />

modern aftermarket<br />

emission control system,<br />

manufactured to OEM quality<br />

standards and above, is<br />

the benchmark for manufacturers<br />

such as Klarius. This<br />

entails close study of OEM<br />

components, combined with<br />

a detailed R&D processes;<br />

trialling aftermarket parts<br />

on vehicles of applicable<br />

make, model and production<br />

year and carrying out<br />

stringent testing to current<br />

legislative standards. Everything<br />

from the size of the<br />

DPF monolith, the quality of<br />

the wash coat & amount of<br />

precious metals inside the<br />

CAT or the consistency of<br />

pipe bend must be exact for<br />

the vehicle to pass current<br />

emissions tests.<br />

Understanding modern<br />

emissions systems, their failure<br />

modes and how to remedy<br />

the cause - not just provide<br />

a replacement, is also<br />

important to manufacturers<br />

such as Klarius. Increasing<br />

complexity means the<br />

need for proper initial training<br />

and refresher courses,<br />

which is why the company<br />

is passing-on its knowledge<br />

to technicians. Klarius has<br />

developed a complete vehicle<br />

emission control system<br />

training course which<br />

has been independently assessed<br />

and accredited by the<br />

IMI to pass on expertise to<br />

garage technicians. Keeping<br />

pace with modern vehicles,<br />

now also means staying<br />

on the upward knowledge<br />

curve.<br />

18, 19 Opinion.indd 2 04/10/2018 11:23