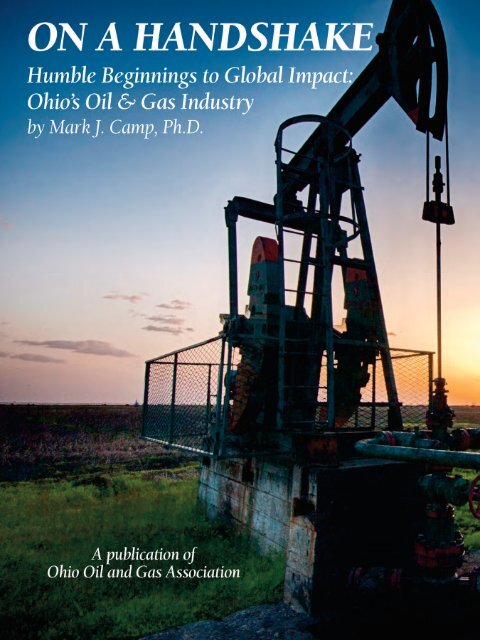

On A Handshake: Humble Beginnings to Global Impact: Ohio's Oil & Gas Industry

An illustrated history of Ohio's oil and gas industry paired with the histories of companies that have helped shape the industry.

An illustrated history of Ohio's oil and gas industry paired with the histories of companies that have helped shape the industry.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Thank you for your interest in this HPNbooks publication. For more information about other<br />

HPNbooks publications, or information about producing your own book with us, please visit www.hpnbooks.com.

ON A HANDSHAKE<br />

<strong>Humble</strong> <strong>Beginnings</strong> <strong>to</strong> <strong>Global</strong> <strong>Impact</strong>:<br />

Ohio’s <strong>Oil</strong> & <strong>Gas</strong> <strong>Industry</strong><br />

by Mark J. Camp, Ph.D.<br />

A publication of the Ohio <strong>Oil</strong> and <strong>Gas</strong> Association<br />

HPNbooks<br />

A division of Lammert Incorporated<br />

San An<strong>to</strong>nio, Texas

Derricks constructed in a shallow former canal reservoir .<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

First Edition<br />

Copyright © 2016 HPNbooks<br />

All rights reserved. No part of this book may be reproduced in any form or by any means, electronic or mechanical, including pho<strong>to</strong>copying, without permission in writing<br />

from the publisher. All inquiries should be addressed <strong>to</strong> HPNbooks, 11535 Galm Road, Suite 101, San An<strong>to</strong>nio, Texas, 78254. Phone (800) 749-9790, www.hpnbooks.com.<br />

ISBN: 978-1-944891-00-8<br />

Library of Congress Card Catalog Number: 2016932414<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

2<br />

<strong>On</strong> a <strong>Handshake</strong>: <strong>Humble</strong> <strong>Beginnings</strong> <strong>to</strong> <strong>Global</strong> <strong>Impact</strong>—Ohio’s <strong>Oil</strong> & <strong>Gas</strong> <strong>Industry</strong><br />

author: Mark J. Camp, Ph.D.<br />

contributing writer for “Sharing the Heritage”: Garnette Bane<br />

Eric Dabney<br />

HPNbooks<br />

president: Ron Lammert<br />

project manager: Mary Hanley<br />

administration: Donna M. Mata<br />

Melissa G. Quinn<br />

book sales: Dee Steidle<br />

production: Colin Hart<br />

Glenda Tarazon Krouse<br />

Evelyn Hart<br />

Tim Lippard<br />

Tony Quinn<br />

Chris<strong>to</strong>pher D. Sturdevant<br />

PRINTED IN MALAYSIA

CONTENTS<br />

4 LEGACY SPONSORS<br />

6 INTRODUCTION<br />

7 ACKNOWLEDGMENTS<br />

9 CHAPTER 1 In the Beginning There was Shale...<br />

13 CHAPTER 2 Ohio’s Subsurface<br />

17 CHAPTER 3 Significant <strong>Oil</strong> and <strong>Gas</strong>-Bearing Rocks of Ohio<br />

21 CHAPTER 4 The First Discoveries of <strong>Gas</strong> and <strong>Oil</strong><br />

31 CHAPTER 5 The Search Spreads<br />

55 CHAPTER 6 Tren<strong>to</strong>n Plays<br />

89 CHAPTER 7 Even Deeper Plays<br />

93 CHAPTER 8 From Discovery <strong>to</strong> Final Product<br />

117 CHAPTER 9 The Marcellus and Utica - 21st Century Boom<br />

121 CHAPTER 10 The Human Side of the <strong>Oil</strong> and <strong>Gas</strong> <strong>Industry</strong><br />

During the Boom Years<br />

146 OHIO OIL AND GAS INDUSTRY TIMELINE<br />

148 SOME GAS AND OIL FIELD TERMS AND PHRASES<br />

150 BIBLIOGRAPHY<br />

153 DATA FROM THE GAS AND OIL FIELDS<br />

163 SHARING THE HERITAGE<br />

165 SHARING THE HERITAGE: EXPLORATION & PRODUCTION<br />

234 SHARING THE HERITAGE: A STRONG FOUNDATION<br />

263 SPONSORS<br />

264 ABOUT THE AUTHOR<br />

C O N T E N T S<br />

3

LEGACY SPONSORS<br />

Through their generous support, these companies helped <strong>to</strong> make this project possible.<br />

Ariel Corporation<br />

35 Blackjack Road Extension<br />

Mount Vernon, OH 43050<br />

740-397-0311 • Fax 740-397-3856<br />

www.arielcorp.com<br />

Bass Energy, Inc.<br />

130 Merz Boulevard<br />

Fairlawn, OH 44333<br />

330-869-8070 • Fax 330-869-6313<br />

www.bassenergyco.com<br />

Dearing Compressor & Pump Co.<br />

3974 Simon Road<br />

Youngs<strong>to</strong>wn, OH 44501<br />

330-599-5720 • Fax 330-599-5724<br />

www.dearingcomp.com<br />

Dominion East Ohio<br />

Dominion Energy Resources<br />

120 Tredegar Street<br />

Richmond, VA 23219<br />

888-366-8280<br />

www.dominionenergy.com<br />

International Union of Operating<br />

Engineers, Local 18<br />

3515 Prospect Avenue<br />

Cleveland, OH 44115<br />

216-432-3138 • Fax 216-432-0370<br />

www.iuoelocal18.org<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

4

J. D. <strong>Gas</strong> & <strong>Oil</strong>, Inc.<br />

J. D. <strong>Gas</strong> & <strong>Oil</strong>, Inc.<br />

6995 Sweetheart Drive<br />

Zanesville, OH 43701-8607<br />

740-796-3305<br />

Moore Well Services, Inc.<br />

246 North Cleveland Avenue<br />

Mogadore, OH 44260<br />

330-628-4443 • Fax 330-628-4449<br />

www.moorewellservices.com<br />

Ohio <strong>Oil</strong> Gathering, LLC<br />

EnLink Midstream<br />

9320 Blackrun Road<br />

Nashport, OH 43830<br />

740-828-2892 • Fax 740-828-3660<br />

www.enlink.com<br />

Vorys, Sater, Seymour and Pease, LLP<br />

52 East Gay Street<br />

Columbus, OH 43215<br />

614-464-6400 • Fax 614-464-6350<br />

www.vorys.com<br />

Wheeling & Lake Erie Railway Company<br />

100 East First Street<br />

Brewster, OH 44613<br />

330-767-3401<br />

www.wlerwy.com<br />

L E G A C Y S P O N S O R S<br />

5

INTRODUCTION<br />

Ohio ranked 17th in oil and gas production in the United States in 2014. Before the Texas and<br />

Oklahoma booms of the early 1900s, Ohio was a leader in national production from 1895 <strong>to</strong> 1903.<br />

This was due <strong>to</strong> the Tren<strong>to</strong>n plays of the Lima-Indiana field which produced over 380 million<br />

barrels of oil and 2 trillion cubic feet of natural gas. A glance at the <strong>Oil</strong> and <strong>Gas</strong> Map of Ohio clearly<br />

shows the his<strong>to</strong>ric binary bands of production—the Lima-Indiana belt in the northwest and the<br />

eastern belt covering the eastern half of the state. The gas fields of eastern Ohio are currently<br />

expanding due <strong>to</strong> the exploration in the Utica shale. Standing out between these two his<strong>to</strong>ric areas<br />

of production are the oil fields of Morrow County.<br />

The following will present a his<strong>to</strong>ry of the development of the oil and gas industry in the<br />

Buckeye state, from the early 1800s <strong>to</strong> present day. The his<strong>to</strong>ry is an erratic one, with one play<br />

following another with no particular relationship <strong>to</strong> age of rock, stratigraphic position, or<br />

geographic location. The plan is <strong>to</strong> present this his<strong>to</strong>ry based on these plays with the addition of<br />

the earliest plays in northeast and southeast Ohio and the current Marcellus and Utica activity. The<br />

state has been divided in<strong>to</strong> regional areas for this discussion, but the boundaries are arbitrary and<br />

sometimes overlap.<br />

Right: A well burns somewhere in<br />

northwestern Ohio.<br />

COURTESY OF THE MAX SHAFFER COLLECTION, WOOD<br />

COUNTY HISTORICAL CENTER & MUSEUM<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

6

ACKNOWLEDGMENTS<br />

This work, like many his<strong>to</strong>ries, is based on the work of many others who collected and<br />

assembled the data, physically witnessed the described events, <strong>to</strong>ok the pho<strong>to</strong>graphs, wrote the<br />

reports and papers, and made the interpretations. To these folks I am sincerely indebted. Thank<br />

you for making sure this information was recorded and preserved for future generations. Finding<br />

this information involved many trips, both physical and virtual, <strong>to</strong> Ohio libraries, museums, and<br />

his<strong>to</strong>rical societies. Through the years my personal library has grown <strong>to</strong> hold considerable geologic<br />

resources, so much data was already on hand. I spent numerous hours at the Toledo Lucas County<br />

Public Library Local His<strong>to</strong>ry room combing through their extensive collections of Ohio his<strong>to</strong>ry<br />

books, journals, newspapers, scrapbooks, and pho<strong>to</strong>s. I revisited the Wood County His<strong>to</strong>rical<br />

Center in Bowling Green <strong>to</strong> scan more pho<strong>to</strong>graphs and documents from the Max Schaffer<br />

collection. The Ohio Department of Natural Resources Division of Geological Survey provided<br />

his<strong>to</strong>ric pho<strong>to</strong>graphs from their collections. Of course, their publications were a major source of<br />

early data on oil and gas. I traveled throughout the Lima-Indiana field visiting many of the ghost<br />

<strong>to</strong>wns and recording what remained. Thanks are also extended <strong>to</strong> the Allen County His<strong>to</strong>rical<br />

Museum, the American Association of Petroleum Geologists, American <strong>Oil</strong> & <strong>Gas</strong> His<strong>to</strong>rical<br />

Society, Bremen Area His<strong>to</strong>rical Society, Center for Archival Collections–Bowling Green State<br />

University, Cleveland Public Library, Cleveland State University, Fairfield County District Library,<br />

Hancock His<strong>to</strong>rical Museum, Little Cities of Black Diamonds, Marietta College, Monroe County<br />

District Library, Monroe County His<strong>to</strong>rical Society, Morgan County Library, New Straitsville<br />

His<strong>to</strong>ry Center, North Baltimore His<strong>to</strong>rical Society, Ohio His<strong>to</strong>rical Society, Perry County Public<br />

Library, Puskarich Harrison County Public Library, Scio His<strong>to</strong>rical Museum, the Southeastern Ohio<br />

Digital Shoebox Project, Tuscarawas County His<strong>to</strong>rical Society, the U.S. Geological Survey, the<br />

Washing<strong>to</strong>n County Public Library, and Wood County District Public Library for maintaining<br />

collections and websites used during this study. Ben Eckart’s website, “His<strong>to</strong>ry of the National<br />

Refining Company” (www.enarco.com) and Samuel T. Pees’ website, “<strong>Oil</strong> His<strong>to</strong>ry”<br />

(http://www.petroleumhis<strong>to</strong>ry.org/<strong>Oil</strong>His<strong>to</strong>ry/OHindex.html), were also valuable resources.<br />

Thanks go <strong>to</strong> my co-author of Ohio <strong>Oil</strong> and <strong>Gas</strong>, Jeff A. Spencer, for sharing some newly acquired<br />

his<strong>to</strong>ric pho<strong>to</strong>graphs not used in our earlier work. I also extend thanks <strong>to</strong> former students—Julius<br />

Blanco of Marathon Petroleum and Kyle Tharp of the Ohio Division of <strong>Oil</strong> & <strong>Gas</strong> and employees<br />

of Chesapeake Energy for arranging field trips for my applied geology class <strong>to</strong> Marathon’s Oregon<br />

s<strong>to</strong>rage facility and a number of drilling sites in eastern Ohio. Mark Baranoski, another former UT<br />

student, of the ODNR Division of Geological Survey arranged for the use of his<strong>to</strong>ric pho<strong>to</strong>graphs.<br />

Thanks, Mark. Tom Boltz of the North Baltimore His<strong>to</strong>rical Society provided me with images from<br />

their fine collection as did Holly Hartlerode, Cura<strong>to</strong>r of the Wood County His<strong>to</strong>rical Center &<br />

Museum. I also thank the Ohio <strong>Oil</strong> & <strong>Gas</strong> Association, for asking me <strong>to</strong> undertake this project.<br />

A C K N O W L E D G M E N T S<br />

7

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

8

CHAPTER ONE<br />

I N T H E B E G I N N I N G T H E R E W A S S H A L E<br />

Five hundred million years ago a shallow sea covered what was <strong>to</strong> become Ohio. The planet had<br />

already been evolving for over four billion years—-small land masses were forming, more<br />

interactions were taking place between the developing atmosphere, erupting volcanoes, and the<br />

land and sea. Rocks that had originally cooled and solidified <strong>to</strong> form the primordial crust were<br />

being broken down by chemicals in the air—often crumbling <strong>to</strong> sand and mud and eventually<br />

finding a way <strong>to</strong> the early oceans. The coarsest particles accumulated along the coastlines and finer<br />

ones clouded the seas. This sediment was the beginning of the vast sedimentary archives of<br />

Earth. The coarser particles were compressed and cemented <strong>to</strong> become conglomerates,<br />

breccias, sands<strong>to</strong>nes, and silts<strong>to</strong>nes; the finer particles became muds<strong>to</strong>nes and shales. In a short<br />

time, this sediment became mixed with the remains of simple micro-organisms—organic matter.<br />

Billions of years passed; year after year more sediment accumulated on <strong>to</strong>p of the previous year’s<br />

deposit. As the Earth evolved so did the organisms — from one-celled creatures <strong>to</strong> complex<br />

invertebrates, vertebrates, and plants. The remains of these organisms—fossils and organic<br />

chemicals – accumulated with the sediments. Thousands of feet of sedimentary rock built up in<br />

some places. In other locales the rocks buckled and broke and were pushed up in<strong>to</strong> mountains,<br />

sometimes accompanied by volcanic eruptions and lava extrusion. The cycle continued as the<br />

uplifted areas were subjected <strong>to</strong> even stronger erosion; resulting in even more sediments. Thus has<br />

been the his<strong>to</strong>ry of our planet. The seas come and go, mountains come and go, lands come and go,<br />

and so on. What nature builds up; nature takes away, but then rebuilds. This is<br />

our his<strong>to</strong>ry.<br />

The sediment that formed in the geologic past is now buried as sedimentary rocks below the<br />

surface of Ohio. We see it occasionally where a stream, river, Lake Erie, or glacial icesheet has cut<br />

in<strong>to</strong> it, underneath our soils. It also appears where we have quarried away the overburden, sunk a<br />

mine shaft, or drilled a well. Because the sediment is of different shapes and sizes, as it settles out<br />

of oceans and other water bodies, there is always pore space between the particles. The coarser the<br />

sediment; the more space between particles. Finer particles also settle with openings among the<br />

particles, but usually of small size. Water from the sea in which the sediment was deposited often<br />

fills many of the pore spaces, especially in sands<strong>to</strong>nes, something geologists call connate water. Of<br />

course, more recent water—freshwater—trickles down in<strong>to</strong> the rocks from the surface. This<br />

groundwater is an important resource and <strong>to</strong>tally saturates pore space at a certain depth called the<br />

water table. Early humans learned of groundwater from places where it rises <strong>to</strong> the surface as springs<br />

or seeps. They also learned that they could contact it by simply digging deep in<strong>to</strong> the ground.<br />

A few of these springs or seeps were salty, others stunk of sulfur, and still others had oily<br />

films or sticky black oozes—-all were evidence of what lay below. The salt came from<br />

ancient seawater and the solution of subsurface evaporite deposits. These lighter density<br />

compounds moved <strong>to</strong>ward the surface whenever given the opportunity. Water reacting with<br />

sulfurous minerals, like pyrite, generated hydrogen sulfide, a gas with a distinctive “rotten egg”<br />

smell. In some places, organic matter from the remains of once living organisms became trapped<br />

among the fine pores of shales and muds<strong>to</strong>nes. Continued compression and an increase in<br />

temperature due <strong>to</strong> deeper and deeper burial of the fine-grained sedimentary rocks eventually<br />

transformed the organics in<strong>to</strong> hydrocarbons—mainly natural gas and oil. Commonly the<br />

hydrocarbons were forced out of the source rock <strong>to</strong> eventually move <strong>to</strong> areas of lower pressure.<br />

This migration might occur over immense amounts of time and result in considerable relocation.<br />

Because of their lighter densities the hydrocarbons tend <strong>to</strong> move upward in the strata through time.<br />

Opposite: Some oil and gas traps displayed<br />

in an east-west cross section across Ohio.<br />

COURTESY OF JOHN WICKS EXPLORATION.<br />

C H A P T E R O N E<br />

9

Right: John Strong Newberry.<br />

All the time, the gas and oil are acquiring the<br />

various changes in chemical composition and<br />

viscosity that will define their future use as<br />

fuels, lubricants, medicine, etc. Migration<br />

ends when either the gas or oil reach the<br />

surface or they are trapped within the rock<br />

strata by changes in the lithology or geologic<br />

structure. If a suitable reservoir rock is<br />

present where conditions terminate the<br />

migration, an accumulation of hydrocarbons<br />

(a pool) may form. This is what petroleum<br />

geologists are looking for.<br />

In the mid-1800s geologists and other<br />

scientists were puzzled by the scattered<br />

occurrence of gas and oil. By the turn of the<br />

century, Ohio geologists were convinced the<br />

gas and oil had an organic origin rather than<br />

an inorganic one favored by certain chemists,<br />

but the details were lacking. By 1899 two<br />

noted Ohio geologists—John Strong<br />

Newberry and Edward J. Or<strong>to</strong>n had published<br />

their thoughts on this matter. In 1859<br />

Newberry reported:<br />

The precise process by which petroleum is<br />

evolved from the carbonaceous matter<br />

contained in the rocks which furnish it is<br />

not yet fully known, because we cannot<br />

in ordinary circumstances inspect it. We<br />

may fairly infer, however, that it is a<br />

distillation, though generally performed at a<br />

low temperature.<br />

He further reports in 1882:<br />

I have already referred <strong>to</strong> the Huron shale<br />

as a probable source of the greater part of the<br />

petroleum obtained in this country…. We<br />

have in the Huron shale a vast reposi<strong>to</strong>ry of<br />

solid hydro-carbonaceous matter which may<br />

be made <strong>to</strong> yield ten <strong>to</strong> twenty gallons of oil <strong>to</strong><br />

the <strong>to</strong>n by artificial distillation. Like all other<br />

organic matter this is constantly undergoing<br />

spontaneous distillation, except where hermetically<br />

sealed deep under rock and water.<br />

This results in the formation of oil and gas,<br />

closely resembling those which we make artificially<br />

from the same substance…. The rock<br />

itself is frequently found saturated with petroleum,<br />

and the overlying strata, if porous, are<br />

sure <strong>to</strong> be more or less impregnated with it.<br />

In 1890, Or<strong>to</strong>n summarized the ideas<br />

about the origin of petroleum:<br />

1. Most geologists hold that petroleum is derived<br />

from organic substances that were<br />

incorporated with the strata when the latter<br />

were formed. There is substantial harmony<br />

among the entire class of geologists as <strong>to</strong><br />

this point.<br />

2. The majority incline <strong>to</strong> the opinion that<br />

vegetable substances have supplied the chief<br />

sources, but some count animal remains as<br />

also an important source. There are a few<br />

authorities upon the subject, chiefly foreign,<br />

who consider animal remains the chief, or<br />

perhaps, the sole source of petroleum.<br />

3. Many hold that it is the result of destructive<br />

distillation of the organic matter of the rocks.<br />

They rely upon such facts as have been<br />

already adduced, that certain shales, for<br />

example, contain a considerable percentage of<br />

hydrocarbonaceous material that is easily<br />

transformed by heat in<strong>to</strong> several products of<br />

the bituminous theory.<br />

4. In accounting for the origin of oil and gas by<br />

destructive distillation of the shale, the<br />

advocates of the theory seem bound <strong>to</strong> furnish<br />

an adequate source of the heat required, and<br />

also <strong>to</strong> show what has become of the carbon<br />

residue that is inseparably connected with the<br />

process of destructive distillation. Real<br />

difficulties beset this theory in these regards.<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

10

The view that destructive distillation is<br />

accomplished at ordinary temperatures would<br />

relieve the first difficulty, if such a process<br />

could be substantiated, but at present it only<br />

stands as an entirely unsupported suggestion.<br />

5. According <strong>to</strong> one phase of this theory,<br />

petroleum is constantly forming in the rocks;<br />

of course, as the world is old, the great s<strong>to</strong>cks<br />

were formed thousands and millions of years<br />

ago. According <strong>to</strong> a second phase of the<br />

theory, the oil of the Allegheny field was<br />

formed at the time when the Appalachian [sic]<br />

mountains were elevated.<br />

6. A small number of geologists hold the view<br />

that petroleum results from the primary<br />

decomposition of organic matter; that the<br />

production is not a lost art of nature, but is in<br />

actual, though perhaps feeble operation at the<br />

present time, its chief seats being in tropical or<br />

subtropical regions. According <strong>to</strong> this view, the<br />

disseminated petroleum that the rocks contain<br />

was formed when the rocks themselves were<br />

formed. Organic matter which is no<strong>to</strong>riously<br />

unstable reaches in the bituminous series its<br />

stage of rest, and we may, therefore, truly<br />

speak of Silurian oil, Devonian oil, Tertiary oil<br />

and the like, the several s<strong>to</strong>cks really having<br />

the age of the beds that hold them.<br />

The<br />

process of oil formation, according <strong>to</strong> this<br />

theory, ceased long ago in the older rocks.<br />

7. The facts upon which the last theory must rest<br />

are not well enough substantiated <strong>to</strong> allow<br />

[sic] as <strong>to</strong> build upon them with full<br />

confidence, but we are justified in looking<br />

upon it with great interest [sic] us it furnishes<br />

on the whole the best explanation of the facts<br />

for which we are obliged <strong>to</strong> account.<br />

Adding <strong>to</strong> the ideas of Newberry and Or<strong>to</strong>n,<br />

Charles B. Morrey, an Ohio State University<br />

Professor of Bacteriology proposed around<br />

1902 that bacteria transformed organic matter<br />

in<strong>to</strong> gas and oil. To quote Dr. Morrey:<br />

In accounting for the origin of oil and gas<br />

from organic matter, geologists have been<br />

unable <strong>to</strong> furnish the agent which might have<br />

brought about the proper decomposition,<br />

since there is no evidence of the action of heat<br />

on the vegetable and animal remains in Ohio<br />

fields at least.<br />

Now the only other agent with which we<br />

are acquainted which can produce the same<br />

compounds as we have in destructive<br />

distillation of organic matter are Bacteria.<br />

So, the gas or oil begins in a source rock,<br />

but because of differing densities, begins <strong>to</strong><br />

move laterally or vertically from its birthplace,<br />

following fractures, pore spaces, and larger<br />

cavities or vugs. This migration continues<br />

until it reaches the surface or something<br />

impedes the movement. Since 1934, this<br />

impediment has been called a trap. A trap<br />

causes the hydrocarbons <strong>to</strong> concentrate and<br />

form a pool. In the mid-1800s geologists<br />

pinpointed the anticline as associated with<br />

oil and gas pools and thus most of the<br />

early searches involved drilling at known<br />

upward bends in the strata. It was soon found<br />

that this was just one of many different ways<br />

in which oil and gas could be caused <strong>to</strong><br />

accumulate. Traps within reservoir rocks are<br />

often divided in<strong>to</strong> structural, stratigraphic,<br />

and combination types.<br />

The hydrocarbons in Ohio reservoir<br />

rocks have been shown <strong>to</strong> be derived<br />

from shales of mainly the Devonian, Sunbury,<br />

Ohio, and Olentangy and Ordovician Point<br />

Pleasant formations, migrating along faults,<br />

fractures, unconformities, and extensive<br />

permeable beds from deep within the<br />

Appalachian basin.<br />

Left: Edward J. Or<strong>to</strong>n.<br />

C H A P T E R O N E<br />

1 1

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

12

CHAPTER TWO<br />

O H I O ’ S<br />

S U B S U R F A C E<br />

The Ordovician strata are covered unconformably by younger rocks <strong>to</strong> the north and east,<br />

beginning with sands<strong>to</strong>nes, shales, limes<strong>to</strong>nes, and dolos<strong>to</strong>nes dating <strong>to</strong> 420 <strong>to</strong> 445 million years<br />

old. This is the Silurian bedrock of western Ohio. It lies beneath the soil and spans from Day<strong>to</strong>n<br />

and Springfield, north <strong>to</strong> Toledo, west <strong>to</strong> the Indiana border, between Preble and Paulding<br />

Counties, and southwest <strong>to</strong> the Ohio River, in Adams County. The deepest Silurian strata contain<br />

the “Clin<strong>to</strong>n”sands<strong>to</strong>ne, which replaced the Tren<strong>to</strong>n as the main producing formation in the state<br />

in the early 1900s. The “Clin<strong>to</strong>n” unit formed in delta distributaries and as offshore bars as the<br />

former Taconic Mountains were being eroded away. The “Clin<strong>to</strong>n” appears as sands<strong>to</strong>ne lenses in<br />

central Ohio and as sheet deposits in the eastern counties. The Silurian rocks form the center of a<br />

series of north-south bands of bedrock in western Ohio. Bands <strong>to</strong> either the west or east of the<br />

Silurian show increasingly younger bedrock—from Devonian <strong>to</strong> Pennsylvanian age, 415- <strong>to</strong> 300-<br />

million- year-old rock. This is part of a gentle upward flexure of the sedimentary rock layers called<br />

the Cincinnati arch in the south and the Findlay Arch in the northern part of the state. This<br />

structure, along with associated fault systems, facies changes, and unconformities plays a role in<br />

the occurrence of oil and gas plays in Ohio, serving as traps for migrating petroleum. From a<br />

sedimentary section of 2,600 feet in northwestern Ohio, strata thickens <strong>to</strong> over 12,000 feet on the<br />

edge of the Appalachian basin in southeastern Ohio.<br />

Later in Silurian time, warm shallow seas returned <strong>to</strong> Ohio. By this time colonial corals<br />

flourished and led <strong>to</strong> the buildup of organic accumulations called reefs. Reef growth spread<br />

throughout the Silurian seas, often bordering areas where slow sinking of bot<strong>to</strong>m sediments were<br />

taking place. These reefs eventually were buried in sediment and covered by younger rock layers.<br />

Their resistance <strong>to</strong> compaction left pores and cavities that later filled with fluids including<br />

petroleum and brines. This is represented by the Newburg horizon of the subsurface, a rather<br />

porous dolos<strong>to</strong>ne which here and there yields natural gas. In late Silurian time, seas withdrew from<br />

Ohio exposing former sea bot<strong>to</strong>ms <strong>to</strong> erosion and leading <strong>to</strong> the evaporation of areas still covered<br />

by seas and the precipitation of dolomite, gypsum and rock salt.<br />

Shallow seas returned around four hundred million years ago during the Devonian Period. <strong>On</strong>ce<br />

again limey and clay-rich sediments accumulated, forming limes<strong>to</strong>nes and shales. In present day<br />

eastern Ohio, rivers flowing out of an upland landscape, carried sands and silts, depositing them<br />

in finger-like deltas reaching the central counties. The Berea Sands<strong>to</strong>ne, another oil producer, is<br />

typical of this deltaic deposition. Surrounding the deltas were subsiding basins where the finegrained<br />

sediments formed organic-rich shales. Late in Devonian time, the sea covering Ohio<br />

received a great influx of mud, forming a thick sequence of organic-rich shales. This led <strong>to</strong> the<br />

Olentangy and Ohio shales, source rock for hydrocarbons. The Devonian bedrock forms two<br />

bands. <strong>On</strong>e extends along the Lake Erie shoreline from Ashtabula <strong>to</strong> Sandusky, then south through<br />

Columbus <strong>to</strong> the Ohio River in Adams and Scio<strong>to</strong> Counties. The other one extends from west of<br />

Toledo <strong>to</strong> the Indiana border with Paulding County. There is also a small erosional remnant at the<br />

crest of the Cincinnati Arch around Bellefontaine in Logan County.<br />

More deltaic deposition—sands<strong>to</strong>nes, silts<strong>to</strong>nes, and shales—characterizes the younger bedrock<br />

of the eastern half of the state. Mississippian strata (318-359 million years old) form the bedrock<br />

just south of the Devonian bedrock from Trumbull <strong>to</strong> Huron Counties and south <strong>to</strong> the Ohio River<br />

and Portsmouth. These rocks form the upland landscape along the edge of the Allegheny Plateau—<br />

the hills of southeastern Ohio. They are best known for their scenic shelter caves, natural arches,<br />

and waterfalls such as seen in Hocking Hills and Mohican State Parks.<br />

Opposite: Ohio geologic map.<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL<br />

RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

C H A P T E R T W O<br />

1 3

Streams and rivers continued <strong>to</strong> shape<br />

ancient Ohio on the far western edge of the<br />

rising Appalachian Mountains during<br />

Pennsylvanian time, some 310 million years<br />

ago. The meandering water courses<br />

periodically carved channels, depositing<br />

pebbles and sand, <strong>to</strong> later become<br />

conglomerates and sands<strong>to</strong>nes. Floodplains<br />

formed from accumulating silt and mud. Low<br />

spots became marshes and swamps where<br />

organic debris eventually led <strong>to</strong> peat and<br />

coal formation. Fluctuating sea levels led<br />

<strong>to</strong> shifting delta complexes which produced<br />

the cyclic depositional-erosional events<br />

recorded in the Pennsylvanian strata.<br />

Petroleum trapped in some of the<br />

Pennsylvanian channel sands led <strong>to</strong> some of<br />

the earliest discoveries in the state. The<br />

Pennsylvanian strata underlie most of the<br />

southeastern counties.<br />

The youngest strata in the state outcrop<br />

from Belmont <strong>to</strong> Washing<strong>to</strong>n Counties<br />

along the Ohio River. These are Permian in<br />

age (299-251 million years old) and are hard<br />

<strong>to</strong> distinguish from the underlying<br />

Pennsylvanian strata. Deltaic deposition<br />

continued until the end of the Paleozoic Era.<br />

Strata of Mesozoic and Cenozoic age are<br />

lacking in the state due <strong>to</strong> the withdrawal of<br />

the shallow seas and slow rise of the<br />

landscape, continuing after the Appalachian<br />

mountain building episode. The present day<br />

landscape owes its origin <strong>to</strong> the erosionaldepositional<br />

processes of great glacial ice<br />

lobes and the ever present modification by the<br />

current drainage systems and Lake Erie.<br />

Opposite: A typical pump jack at a well in<br />

Jackson Township, Knox County, in 1953.<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL<br />

RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

14

C H A P T E R T W O<br />

1 5

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

16

CHAPTER THREE<br />

S I G N I F I C A N T O I L A N D G A S - B E A R I N G R O C K S O F O H I O<br />

The first Ohio strata discovered <strong>to</strong> contain hydrocarbons were shallow sands<strong>to</strong>nes from the<br />

Allegheny plateau of the southeastern counties. As settlers headed in<strong>to</strong> the hills bordering the Ohio<br />

and Muskingum Rivers they noted numerous oil and gas seeps or springs. With just a little shallow<br />

digging they saw that the fluids were coming from the bedrock and eventually using primitive<br />

methods drilled shallow wells. <strong>On</strong>e of the first tasks of the newly created State Geological Survey<br />

was <strong>to</strong> uncover the mineral resources of the state. By 1900, state geologists had reported on most<br />

of the gas- and oil- bearing strata of the state. The main producers are listed in stratigraphic order,<br />

that is from oldest <strong>to</strong> youngest.<br />

T H E R O S E R U N<br />

The Rose Run sands<strong>to</strong>ne has been an important source of gas and oil since its initial discovery<br />

in 1965. It is part of the much thicker Cambro-Ordovician Knox dolomite and stretches in the<br />

subsurface in a Northeast-Southwest band from Ashtabula <strong>to</strong> Pickaway County. It was named for<br />

a well site in Bath County, Kentucky. The sands<strong>to</strong>ne is medium <strong>to</strong> coarse grained, dolomitic in<br />

places, and poorly sorted. It is considered Late Cambrian in age.<br />

T H E<br />

T R E N T O N<br />

Named after outcrops first described in Tren<strong>to</strong>n Township, <strong>On</strong>eida County, New York, this<br />

Ordovician limes<strong>to</strong>ne-dolos<strong>to</strong>ne is in the subsurface of Ohio, but closest <strong>to</strong> the surface<br />

in northwestern Ohio. It led <strong>to</strong> the Findlay gas boom in 1884 and the discovery of oil at Lima,<br />

the next year. Around sixty thousand producing gas and oil wells were drilled <strong>to</strong> this<br />

horizon. Production from the Tren<strong>to</strong>n pushed Ohio <strong>to</strong> one of the <strong>to</strong>p producers in the country<br />

in the 1890s.<br />

A generalized column of bedrock units<br />

in Ohio.<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL<br />

RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

T H E U T I C A S H A L E<br />

This organic-rich Ordovician shale lies in the subsurface of much of Ohio. It is interbedded with<br />

thin beds of fossiliferous limes<strong>to</strong>ne. It varies in thickness from 0 <strong>to</strong> 340 feet, becoming thicker in<br />

the Appalachian basin. Upon stimulation the strata yields gas and some oil.<br />

T H E C L I N T O N S A N D<br />

The Clin<strong>to</strong>n sand has been a major source of natural gas in Ohio and ranks just behind the Tren<strong>to</strong>n<br />

in terms of oil production. Although the name suggests correlation with the Silurian Clin<strong>to</strong>n group—<br />

mainly carbonate strata of New York; it is instead equivalent <strong>to</strong> the older Silurian Medina group—<br />

sands<strong>to</strong>nes, silts<strong>to</strong>nes, and shales of New York. In Ohio’s subsurface the Medina is informally referred<br />

<strong>to</strong> as the Clin<strong>to</strong>n in the eastern counties and is correlative <strong>to</strong> the Brassfield formation in the western<br />

part of the state. Drillers recognize three parts of the Clin<strong>to</strong>n—the stray Clin<strong>to</strong>n, red Clin<strong>to</strong>n, and<br />

white Clin<strong>to</strong>n. In appearance perhaps it best compares <strong>to</strong> the Silurian Whirlpool sands<strong>to</strong>ne exposed<br />

in the Niagara gorge. Wells tap the Clin<strong>to</strong>n from Cuyahoga <strong>to</strong> Lawrence Counties, across the midsection<br />

of the state. Its value as a producer became recognized in 1887 when drilling below the Berea<br />

hit a strong gas flow in the Clin<strong>to</strong>n near Lancaster in Fairfield County.<br />

C H A P T E R T H R E E<br />

1 7

The Clin<strong>to</strong>n sand varies from fine <strong>to</strong> coarse<br />

grained with generally good porosity, but<br />

because of a tendency <strong>to</strong> be well cemented,<br />

lacks the permeability of some other strata.<br />

Within the sands<strong>to</strong>ne are scattered thin beds<br />

of shale—known as breaks <strong>to</strong> the driller.<br />

Thickness ranges from 1 <strong>to</strong> 100 feet, but it<br />

averages 20 <strong>to</strong> 40 feet.<br />

By the late 1940s, the success rate of<br />

Clin<strong>to</strong>n wells had diminished, around fifty<br />

percent were recorded as dry holes. Much of<br />

the industry was convinced that the Clin<strong>to</strong>n<br />

was played out. In the early 1950s, hydraulic<br />

fracturing experiments showed that<br />

production rates could be greatly increased. A<br />

renewed interest in the Clin<strong>to</strong>n resulted. The<br />

year 2000 marked another increase in drilling<br />

<strong>to</strong> the Clin<strong>to</strong>n horizon. According <strong>to</strong> the Ohio<br />

<strong>Oil</strong> and <strong>Gas</strong> Association, the average depth <strong>to</strong><br />

the Clin<strong>to</strong>n was 4,792 feet and the average<br />

cost of completing a well was $175,000.<br />

T H E N E W B U R G S A N D<br />

This Silurian gas producer was first noted<br />

in a gas well drilled in Newburg in Cuyahoga<br />

County. The “sand’ is actually a sandy<br />

dolos<strong>to</strong>ne equivalent <strong>to</strong> the Guelph-<br />

Greenfield contact of western Ohio. Its<br />

thickness averages 8 <strong>to</strong> 15 feet. The Newburg<br />

often contains large volumes of saltwater and<br />

is also referred <strong>to</strong> by drillers as the Big Water.<br />

T H E O R I S K A N Y S A N D<br />

This Devonian gas producer is known only<br />

from the subsurface of northeastern Ohio as<br />

discontinuous patches bounded above and<br />

below by disconformities. It lies below the<br />

Columbus limes<strong>to</strong>ne and above the Bass<br />

Islands dolomite. The stratum averages<br />

between 10 and 30 feet thick. Wells producing<br />

from this horizon were mainly in Ashtabula,<br />

Guernsey, and Tuscarawas Counties.<br />

T H E O H I O S H A L E<br />

This Upper Devonian gas-bearer outcrops<br />

from Erie County south <strong>to</strong> Scio<strong>to</strong> County, east<br />

along Lake Erie from the Huron area <strong>to</strong><br />

Conneaut, and around Bellefontaine in Logan<br />

County. It is in the subsurface of eastern Ohio<br />

and is equivalent <strong>to</strong> the subsurface Antrim<br />

shale of northwestern Ohio. It occurs as thin<br />

organic-rich beds from 250 <strong>to</strong> greater than<br />

500 feet in outcrop. Known by drillers as Big<br />

and Little Cinnamon, the Ohio shale thickens<br />

in the subsurface <strong>to</strong> over 4,000 feet.<br />

T H E B E R E A S A N D O R<br />

B E R E A G R I T<br />

The Berea sand was the earliest stratum<br />

discovered <strong>to</strong> yield commercial quantities of oil<br />

in Ohio. It was named by John Strong Newberry<br />

for surface outcrops near Berea, Cuyahoga<br />

County in 1869. The Berea sands<strong>to</strong>ne outcrops<br />

from Cuyahoga County east along the Lake Erie<br />

shore and south across the middle counties <strong>to</strong><br />

Scio<strong>to</strong> County on the Ohio River. In the eastern<br />

counties, it lies in the subsurface.<br />

The Berea is characterized by fine <strong>to</strong><br />

medium grain size sands<strong>to</strong>nes with scattered<br />

layers of sandy shale. The strata vary from<br />

thin <strong>to</strong> thick, planar <strong>to</strong> lenticular beds. The<br />

unit varies in thickness from 1 <strong>to</strong> 155 feet.<br />

T H E B I G I N J U N S A N D<br />

This subsurface stratum of eastern Ohio is<br />

correlative with the Mississippian Cuyahoga<br />

Formation Black Hand Sands<strong>to</strong>ne. This<br />

member stretches from Cuyahoga County<br />

south <strong>to</strong> the Ohio River and Scio<strong>to</strong> County<br />

and inland from Lake Erie from Cuyahoga <strong>to</strong><br />

Ashtabula Counties. It contains beds of<br />

sands<strong>to</strong>ne, conglomerate, and shale. The<br />

sands<strong>to</strong>ne beds tend <strong>to</strong> be coarse-grained and<br />

mainly yield gas and saltwater. The general<br />

thickness is 70 <strong>to</strong> 120 feet. His<strong>to</strong>rically, the<br />

Big Injun has been a good producer in<br />

Monroe and Washing<strong>to</strong>n Counties and <strong>to</strong> a<br />

smaller extent in Athens, Belmont, Guernsey,<br />

Morgan, and Noble Counties.<br />

T H E K E E N E R S A N D<br />

This Middle Mississippian sands<strong>to</strong>ne lies<br />

above the Big Injun sand in the subsurface of<br />

eastern Ohio. It was named for farm property<br />

in the Sistersville, West Virginia pool. It is<br />

correlative with the Mississippian Logan<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

18

formation that crops out in south central Ohio.<br />

Its thickness averages 25 <strong>to</strong> 35 feet and consists<br />

of alternating layers of coarse- and fine-grained<br />

sands<strong>to</strong>ne. Most production has come from<br />

Athens, Belmont, Guernsey, Monroe, Morgan,<br />

Noble, and Washing<strong>to</strong>n Counties.<br />

T H E M A X T O N S A N D<br />

Found in the subsurface of eastern Ohio<br />

this oil-bearing sands<strong>to</strong>ne correlates with the<br />

Pennsylvanian Pottsville Group Sharon<br />

conglomerate/sands<strong>to</strong>ne. The Max<strong>to</strong>n was<br />

first encountered in the Sistersville pool of<br />

West Virginia. Outcrops of the Sharon occur<br />

in northeastern and southern Ohio. The<br />

Max<strong>to</strong>n consists of interbedded medium- <strong>to</strong><br />

coarse-grained sands<strong>to</strong>ne, pebbly sands<strong>to</strong>ne,<br />

and conglomerate. The stratum varies from 10<br />

<strong>to</strong> 200 feet in thickness.<br />

T H E M A C K S B U R G 7 0 0<br />

This subsurface stratum forms the <strong>to</strong>p of the<br />

Pennsylvanian Pottsville group in southeastern<br />

Ohio and is equivalent <strong>to</strong> the Homewood<br />

sands<strong>to</strong>ne. It is present as a discontinuous lens<br />

in the subsurface of Monroe, Morgan, Noble,<br />

and Washing<strong>to</strong>n Counties.<br />

T H E M A C K S B U R G<br />

5 0 0 - F O O T S A N D<br />

A major producer from the Pennsylvanian<br />

Allegheny group in southeastern Ohio, this<br />

sands<strong>to</strong>ne correlates with the Clarion<br />

sands<strong>to</strong>ne and is widespread in the subsurface.<br />

It ranges in thickness between 10 and 50 feet.<br />

It was part of the original explora<strong>to</strong>ry drilling<br />

in the Macksburg area in the early 1860s.<br />

S E C O N D C O W R U N S A N D /<br />

P E E K E R S A N D<br />

Discovered in drilling along Cow Run in<br />

Washing<strong>to</strong>n County, this subsurface<br />

sands<strong>to</strong>ne is equivalent <strong>to</strong> the Upper Freeport<br />

sands<strong>to</strong>ne of the Allegheny group. Although<br />

not a major source of gas or oil, production<br />

has come from Monroe, Morgan, Noble, and<br />

Washing<strong>to</strong>n Counties.<br />

T H E M A C K S B U R G<br />

3 0 0 - F O O T S A N D<br />

The base of the Conemaugh strata is<br />

marked by this lens of sands<strong>to</strong>ne, occasionally<br />

a minor producer of oil and gas. It was first<br />

discovered in drilling around Macksburg,<br />

Washing<strong>to</strong>n County. It is correlative with the<br />

Mahoning sands<strong>to</strong>ne and occurs sporadically<br />

in the southeastern counties.<br />

T H E F I R S T C O W R U N S A N D<br />

This Pennsylvanian Conemaugh Group<br />

sands<strong>to</strong>ne outcrops along the Muskingum<br />

River and its tributaries. It is in the shallow<br />

subsurface of eastern Ohio. It was named from<br />

drilling along Cow Run, Washing<strong>to</strong>n County.<br />

The unit is massive, coarse-grained <strong>to</strong> pebbly<br />

and ranges between 5 and 40 feet thick. It<br />

averages about 25 feet thick. It occurs in the<br />

subsurface of eastern Ohio, but is most<br />

prominent in Athens, Morgan, Muskingum,<br />

Noble, and Washing<strong>to</strong>n counties.<br />

C H A P T E R T H R E E<br />

1 9

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

20

CHAPTER FOUR<br />

T H E F I R S T D I S C O V E R I E S O F G A S A N D O I L<br />

L O O K I N G F O R S A L T<br />

Settlement of the lands west of the Allegheny Mountains in the years after the Revolutionary<br />

War was a slow process and only for the most hardy. Among the many hardships was preserving<br />

foodstuffs in the wilderness. The pioneers were familiar with salt as a preservative from the old<br />

country and shortly discovered it could be found in the hills of what was <strong>to</strong> become southeast<br />

Ohio. They were helped by the fact that deer and bison had already discovered sites where brine<br />

came <strong>to</strong> the surface. Native Americans also pointed out places where salt was available. Salt licks<br />

and springs appear on early maps. It is without doubt that the discovery of salt in the bedrock of<br />

the Ohio and Muskingum River drainage and the development of the salt industry laid foundations<br />

for this part of the Northwest Terri<strong>to</strong>ry <strong>to</strong> become a state in 1803. Before these discoveries, most<br />

salt was laboriously hauled over the mountains by wagon and pack animal.<br />

Aside from springs along the major drainage courses, among the first lands <strong>to</strong> be developed for<br />

salt manufacture were the flats along Little Salt Creek near the present city of Jackson. This site was<br />

easily discovered following well-worn paths left by herds of bison that made frequent trips <strong>to</strong> the<br />

site up until about 1800. Native Indians were the first <strong>to</strong> evaporate the brines, crystalizing the salt.<br />

They hollowed out shallow pits in the Pennsylvanian sands<strong>to</strong>ne exposed along the creek bed<br />

during the dry season, dipped out the brine that filled the depressions, and boiled it.<br />

As the brine was generally a weak solution, enterprising settlers figured that the brine would be more<br />

concentrated at depth as it was in the old country. Thus, wells were first dug by hand, but this limited<br />

their depth and often did not yield the results wanted. The blacksmith became a valuable addition <strong>to</strong><br />

this developing landscape. Augers and drills allowed the deepening of the salt wells, but then another<br />

problem arose. Since most of the early drilling <strong>to</strong>ok place in valleys, bedrock was further down so<br />

digging was mainly in valley fill, but eventually the deeper wells hit resistant rock. A simple auger no<br />

longer worked and new ways of drilling had <strong>to</strong> be developed. Percussion drilling was the answer.<br />

The Scio<strong>to</strong> Saline, as the Jackson County salt plains became known, was the earliest recorded attempt<br />

at making salt in what was <strong>to</strong> become Ohio, around 1795. Later on, attempts by the state legislature <strong>to</strong><br />

control development of salt mining encouraged deeper drilling and exploring away from springs and<br />

licks. It was only a matter of time before more drillers were encountering petroleum and natural gas.<br />

The first salt wells bored in Columbiana County <strong>to</strong>ok place around a series of salt springs at a<br />

location that would become Salineville in 1839. The first wells produced more gas and water than<br />

salt, but by 1818 the production was finally satisfac<strong>to</strong>ry. The climax seems <strong>to</strong> have been around<br />

1835 when twenty wells were producing in the valley of Yellow Creek. Although salt production<br />

declined after 1835 the business still remained profitable until around 1865. Inves<strong>to</strong>rs looking for<br />

oil in 1866, revived the industry when they struck high pressure gas and saltwater, rather than oil.<br />

The last salt production in Columbiana County was 1880.<br />

The early salt industry lives on in the names of creeks and villages across the state—places like the<br />

many Salt Creeks, Salt Forks, Salt Runs, and Salineville, but after the success of the 1859 Drake well<br />

in nearby Pennsylvania, drillers shifted their focus <strong>to</strong> the black smelly contaminant of many salt wells.<br />

Opposite: <strong>Oil</strong> still fills the hollowed-out log<br />

casing of one of the 1814 Thorla-McKee<br />

wells near Caldwell.<br />

COURTESY OF JEFF A. SPENCER.<br />

F R O M N U I S A N C E T O A U S E A B L E P R O D U C T<br />

Perhaps among the earliest references <strong>to</strong> an oil spring in what was <strong>to</strong> become Ohio is one by early<br />

explorers of the Ohio Valley near Macksburg, Washing<strong>to</strong>n County in 1787. Later in 1814, Robert<br />

C H A P T E R F O U R<br />

2 1

Above: Dr. Samuel P. Hildreth of Marietta,<br />

McKee and Silas Thorla drilled for salt at a<br />

deer lick along Salt Run near present day<br />

Caldwell, Noble County. Using the spring pole<br />

drilling method, the well struck salt, oil, and<br />

natural gas a couple hundred feet down. A<br />

second, somewhat deeper, well was drilled in<br />

1816 with the same results. Due <strong>to</strong> lack of<br />

competition in the area the saltworks thrived<br />

for about ten years. To get good saleable salt,<br />

the oil had <strong>to</strong> be separated from the brine;<br />

initially it was considered a great nuisance.<br />

Perhaps learning from the native population,<br />

the owners began marketing the oil as a<br />

cure-all.<br />

Dr. Samuel P. Hildreth, a Marietta<br />

physician, was also well versed in the sciences<br />

and wrote numerous articles about the natural<br />

his<strong>to</strong>ry of southeastern Ohio and surrounding<br />

Virginia (now West Virginia). In 1826, he<br />

reported on the McKee well in a letter <strong>to</strong><br />

Caleb Atwater of Circleville, another early<br />

investiga<strong>to</strong>r of Ohio geology and natural<br />

his<strong>to</strong>ry. The letter was published in Benjamin<br />

Silliman’s American Journal of Science out of<br />

Yale University. Hildreth also reported that oil<br />

and natural gas was found commonly in the<br />

Muskingum Valley:<br />

“They have sunk two wells which are now<br />

more than 400 feet in depth. <strong>On</strong>e of them<br />

affords a very strong and pure water, but not<br />

in great quantity. The other discharges such<br />

vast quantities of petroleum, or as it is<br />

vulgarly called ‘Seneka oil’, and besides is<br />

subject <strong>to</strong> such tremendous explosions of gas<br />

for several days that they make but little or no<br />

salt. Nevertheless, the petroleum, affords<br />

considerable profit, and is beginning <strong>to</strong> be in<br />

demand for lamps, in workshops and<br />

manufac<strong>to</strong>ries. It affords a clean, brisk light<br />

when burnt this way, and will be a valuable<br />

article for lighting the street lamps in the<br />

future cities of Ohio.<br />

There is a continual discharge of<br />

carbonated hydrogen gas from the well; and<br />

also from the bed of the creek on which the<br />

well is situated at various places for the<br />

distance of half a mile. This gas is highly<br />

inflammable, and where there is a free<br />

discharge of it, will take fire on the surface of<br />

the water, on application of a lighted stick, or<br />

flash of a gun, and continue burning for days,<br />

unless put out by a heavy shower or a high<br />

wind. It was this discharge of gas that induced<br />

the present proprie<strong>to</strong>rs <strong>to</strong> search for saltwater.<br />

It being invariably found <strong>to</strong> accompany,<br />

all the salt-water, of any consequence, that has<br />

been discharged in this western country.”<br />

Dr. Hildreth traveled throughout<br />

southeastern Ohio and Virginia, making notes<br />

on the archaeology, botany, geology and other<br />

<strong>to</strong>pics of natural his<strong>to</strong>ry. By 1833 he found<br />

hydrocarbons being used for illumination,<br />

medicine, and lubrication throughout this<br />

region. Much of the early expertise in drilling<br />

salt wells, and later oil wells came from the<br />

Virginia side of the Ohio River between<br />

Charles<strong>to</strong>n and Parkersburg. The Ruffner<br />

Brothers are credited with developing a series<br />

of techniques that allowed them <strong>to</strong> drill wells<br />

in<strong>to</strong> the bedrock along the Kanawha River<br />

Valley at what is now Charles<strong>to</strong>n, West<br />

Virginia, in 1806. It appears they were familiar<br />

with methods of removing s<strong>to</strong>ne in quarries<br />

and applied those <strong>to</strong> the drilling of salt wells<br />

in<strong>to</strong> the bedrock. They also found a way <strong>to</strong><br />

incase the upper part of a well <strong>to</strong> prevent<br />

groundwater from diluting the brine and<br />

causing collapse of the well margins. Soon<br />

these techniques were applied throughout the<br />

salt industry.<br />

A brief description of Marietta and<br />

surrounding Washing<strong>to</strong>n County published<br />

in 1834 by John Delafield, Jr. mentioned<br />

spring oil or Seneca oil was familiar <strong>to</strong><br />

hunters and early inhabitants since the<br />

first settlement. Delafield reports, "It can<br />

be used in lamps as it affords a brilliant<br />

light. It is very useful and therefore much<br />

employed in curing the diseases of and<br />

injuries done <strong>to</strong> horses. It is perhaps the best<br />

substance known for the prevention of<br />

friction in machinery."<br />

Up north, settlers as early as the 1850s,<br />

wrote of gas and oil springs in what was <strong>to</strong><br />

become Lorain County. In 1857 reports came<br />

of flaming gas jets southwest of South<br />

Amherst. Similar areas of burning gas were<br />

observed in the Black River valley at Sheffield.<br />

Successful gas wells were put down at Avon,<br />

Lagrange, Pittsfield, and Russia. By 1915, 17<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

22

gas wells were producing about 10 million<br />

cubic feet per day. A single Avon well was<br />

responsible for about half this production.<br />

The gas was from the Ohio shale and would<br />

prove short-lived. Pits were dug where oil was<br />

seen on the surface at Belden so the oil could<br />

be collected and sold as a cure-all. Around<br />

1860 a salt well was drilled and, at a depth of<br />

120-140 feet, oil was struck in the Devonian<br />

Berea Sands<strong>to</strong>ne. This initial play drew<br />

wildcatters <strong>to</strong> the area and soon the area<br />

was riddled with holes. <strong>On</strong>e well yielded<br />

about 145 barrels the first day; a couple<br />

others also had good yields, but overall the<br />

average production was 3 <strong>to</strong> 5 barrels a day.<br />

Initially the oil was not highly regarded<br />

because of its viscosity. There was hope that it<br />

could be distilled <strong>to</strong> make kerosene. The oil<br />

was soon found <strong>to</strong> be a good lubricant, but<br />

after about twenty-five years the field was<br />

essentially abandoned.<br />

A pioneer in distributing petroleum was<br />

the firm of Bosworth Wells & Co. of Marietta.<br />

They purchased oil from men mining it in<br />

sand pits along the Hughes River in<br />

neighboring Virginia in the early 1840s. The<br />

firm started out buying it for twenty-five cents<br />

a gallon, marketing it as “Seneca <strong>Oil</strong>” for<br />

medicinal purposes and then selling it <strong>to</strong> a<br />

New York City drug company for ninety cents<br />

a gallon. The oil was shipped down the Ohio<br />

and Mississippi Rivers <strong>to</strong> New Orleans and up<br />

the Atlantic coast <strong>to</strong> New York. Bosworth &<br />

Wells continued dealing in the Virginia oil<br />

until the early 1850s shipping it across the<br />

continent <strong>to</strong> dealers making all kinds of<br />

medicinal oils and liniments. The Drake<br />

discovery in 1859 greatly impacted the<br />

company’s business, since now crude oil<br />

became much more available and cut in<strong>to</strong> the<br />

company’s profits.<br />

A N E A R L Y P L A Y I N<br />

T H E B E R E A S A N D S T O N E —<br />

T H E M E C C A F I E L D<br />

Aside from these scattered encounters at<br />

salt wells and furnaces, the first true oil play<br />

in Ohio <strong>to</strong>ok place at the small Trumbull<br />

County community of West Mecca in 1860.<br />

This area is underlain by glacial till and about<br />

forty feet of Devonian Berea Sands<strong>to</strong>ne which<br />

served as an aquifer for early settlers sinking<br />

water wells along Mosqui<strong>to</strong> Creek. However<br />

early residents were frustrated, as often<br />

retrieved water had an oily surface film. So,<br />

small quantities of oil were soaked up with<br />

rags and used as a cure-all.<br />

<strong>Oil</strong> seekers spreading in<strong>to</strong> Ohio after the<br />

Drake discovery were on the lookout for<br />

likely places <strong>to</strong> drill. News of the oily wells<br />

soon reached them. The first few wells yielded<br />

oil at depths of only 45 <strong>to</strong> 60 feet at rates of<br />

around 40 barrels a day. The early production<br />

far exceeded the market and the start of the<br />

Civil War in 1861 practically ended any<br />

further work in the field. Some time between<br />

1861-65, an attempt was made <strong>to</strong> mine the<br />

Berea for its oil (a technique that had been<br />

successful in the 1840s in Virginia). Three<br />

shafts were sunk <strong>to</strong> the Berea. Tunnels were<br />

then dug in the Berea with the hope of<br />

intersecting a nearby valley where it was<br />

expected the oil would flow out of the<br />

tunnels. The project became more challenging<br />

than expected and was never finished. A<br />

refinery or two operated in the region in the<br />

early years, but the operations were<br />

apparently unsuccessful as they were<br />

abandoned in a few years. After the Civil War,<br />

wildcatters eventually put down some 2,000<br />

<strong>to</strong> 2,500 wells in the area, most no deeper<br />

than 50 feet. In later years, a few wells were<br />

drilled as deep as the Ohio Shale, including<br />

one as deep as 1,135 feet, but none proved <strong>to</strong><br />

be productive. The field was a relatively small<br />

one, covering about fifteen square miles. Most<br />

of the production was from an area of a few<br />

hundred acres. The oil was a thick dense<br />

variety, quite different from that underlying<br />

the Pennsylvania <strong>Oil</strong> Creek field. It was<br />

marketed as lubricating oil, fetching prices<br />

as high as $50 per barrel in places like<br />

Pittsburgh and Cleveland. <strong>On</strong>ly minor<br />

amounts of gas were associated with the<br />

Mecca field. During the best year an estimated<br />

5,000 barrels of oil were pumped from this<br />

field. Most wells were short-lived, producing<br />

only trickles by the 1880s.<br />

In 1884, on the west side of the Mecca<br />

field, drillers once again attempted <strong>to</strong> mine the<br />

oil sand by excavating a shaft down <strong>to</strong><br />

C H A P T E R F O U R<br />

2 3

T H E M A C K S B U R G A N D C O W<br />

R U N F I E L D S : T H E S T A R T O F<br />

S O U T H E A S T E R N O H I O O I L<br />

A N D G A S P R O D U C T I O N<br />

Above: Although details are sketchy, this is<br />

thought <strong>to</strong> be a view in the Cow Run field of<br />

Washing<strong>to</strong>n County probably in the late<br />

1860s.. Note the spring pole rigs and open<br />

wooden s<strong>to</strong>rage tanks.<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL<br />

RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

Below: Another early view of probably the<br />

Cow Run field near Marietta. Note that the<br />

wells are all in the valley bot<strong>to</strong>m.<br />

COURTESY OF THE U.S. DEPARTMENT OF AGRICULTURE<br />

FOREST SERVICE.<br />

the Berea Sands<strong>to</strong>ne and then running<br />

tunnels through the bed. Although plentiful<br />

quantities of sand were removed, the mine was<br />

shortly abandoned. The community of West<br />

Mecca became a classic boom<strong>to</strong>wn in the<br />

1860s. Now most of the area lies at the bot<strong>to</strong>m<br />

of the Mosqui<strong>to</strong> Lake Reservoir, completed in<br />

April, 1944. Many of the structures were<br />

moved <strong>to</strong> Cortland and Warren. West Mecca<br />

and Mecca continue as small communities, but<br />

attention is now focused on the recreational<br />

activities created by the reservoir.<br />

<strong>Oil</strong> in the Duck Creek valley of Noble and<br />

Washing<strong>to</strong>n Counties was well known due <strong>to</strong><br />

the active salt industry, a couple of burning<br />

springs, and the 1814 Thorla and McKee well.<br />

It was only natural that the Drake discovery<br />

led locals <strong>to</strong> investigate the many oil seeps<br />

and gas springs north of Marietta. As Spring<br />

arrived in 1860, a well was drilled for the sole<br />

purpose of finding oil. Unfortunately it was a<br />

dry hole. Another well was put down in the<br />

fall on a farm just south of Macksburg in<br />

Washing<strong>to</strong>n County. The well was driven by a<br />

special type of hand lever, not the traditional<br />

spring pole. At 59 feet down oil was struck.<br />

It was a very viscous oil, unlike the<br />

Pennsylvania oil. Disappointment turned <strong>to</strong><br />

joy when the oil was found <strong>to</strong> be a valuable<br />

lubricant and garnered $28 per barrel. It was<br />

taken by wagon <strong>to</strong> the Muskingum River port<br />

of Lowell where it was shipped by boat <strong>to</strong><br />

Marietta and up the Ohio River <strong>to</strong> Pittsburgh.<br />

Another such investigation <strong>to</strong>ok place in 1861<br />

on the Uriah S. Dye and Samuel Dye farmsteads<br />

<strong>to</strong> the south at Cow Run by inves<strong>to</strong>rs<br />

led by John New<strong>to</strong>n of Marietta. <strong>Gas</strong> periodically<br />

bubbled <strong>to</strong> the surface along Cow Run<br />

and there had been unsuccessful attempts <strong>to</strong><br />

use the gas as a fuel by a nearby cooper. Hard<br />

work at the spring pole eventually led <strong>to</strong> a<br />

good play of oil at 137 feet, with wells averaging<br />

about 50 barrels per day. The oil was<br />

hauled by wagon <strong>to</strong> Marietta, then by packet<br />

boat down the Ohio and up the Mississippi <strong>to</strong><br />

a refinery in St. Louis.<br />

The successes at Macksburg and Cow Run<br />

fields led <strong>to</strong> an oil boom. Stretching on both<br />

sides of the Ohio River around Marietta and<br />

Parkersburg, north <strong>to</strong> Caldwell, wooden<br />

derricks dotted the stream valleys. Then 1861<br />

brought the start of the Civil War and a<br />

slowdown <strong>to</strong> oilfield activity. The early boom<br />

was greatly speculative; the payout was less<br />

than expected, great expense was required <strong>to</strong><br />

get the oil <strong>to</strong> market, and, as more oil became<br />

available, the price per barrel decreased. The<br />

first Macksburg boom was short and not so<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

24

sweet. After the war, geology played a much<br />

more important role in the development of<br />

wells. George Rice’s gusher of 150 barrels in<br />

1874 rekindled interest in the Macksburg area.<br />

From 1872 <strong>to</strong> the mid-1880s much of Noble<br />

and Washing<strong>to</strong>n Counties were under lease <strong>to</strong><br />

various oil companies. These companies<br />

included Acme <strong>Oil</strong>, Archer’s Fork <strong>Oil</strong> of<br />

Marietta, Bergen <strong>Oil</strong> and Coal of New York,<br />

Bos<strong>to</strong>n Petroleum and Mining, Cincinnati<br />

Petroleum, Crescent Petroleum of Bos<strong>to</strong>n,<br />

Duck Creek Petroleum and Mining of<br />

Cincinnati, Eagle <strong>Oil</strong> Association of New York,<br />

Equitable Petroleum of New York, Exchange<br />

<strong>Oil</strong>, Germania <strong>Oil</strong>, Lowell <strong>Oil</strong>, “Madison <strong>Oil</strong>”,<br />

Marietta Mining of New York, Marietta <strong>Oil</strong><br />

of Bos<strong>to</strong>n, Moorehead <strong>Oil</strong>, New Jersey <strong>Oil</strong>,<br />

Ohio <strong>Oil</strong> and Mining of Marietta, Putnam<br />

Petroleum of Day<strong>to</strong>n, Union Coal of Marietta,<br />

Williamsport and Ohio Petroleum, and<br />

Willow Glen Petroleum of Philadelphia. These<br />

companies brought improved technology and<br />

equipment for drilling wells, including the<br />

first steam engines and new drilling bits.<br />

Exploration centered on the southern field<br />

around Cow Run and the northern or<br />

Macksburg field around Macksburg.<br />

Then in the 1880s, due <strong>to</strong> deep drilling<br />

plays in the Devonian Berea Sands<strong>to</strong>ne, the<br />

boom returned <strong>to</strong> Macksburg. By August,<br />

1883, monthly production was 4,600 barrels,<br />

now transported by pipeline <strong>to</strong> refineries in<br />

Parkersburg,West Virginia. A peak in monthly<br />

production of 79,737 barrels was reached in<br />

July, 1885. Production declined slowly<br />

around Macksburg. According <strong>to</strong> a March 31,<br />

1887 report, 466 wells were producing an<br />

average of 66 barrels a month in an area of<br />

roughly 4,000 acres. The oil plays came in at<br />

depths of 1,425 feet below the valleys and<br />

1,900 feet under the uplands. Unfortunately,<br />

by 1900, it was evident that the deeper plays<br />

were not as successful as anticipated. Drillers<br />

headed <strong>to</strong> greener pastures.<br />

The Macksburg area is unique among oil<br />

fields in having a large number of oil-saturated<br />

sands. The first oil was encountered in a thin<br />

discontinuous band of sand only 59 feet<br />

down. Drilling deeper brought a strong play in<br />

Above: Farm fields yield <strong>to</strong> derricks in the<br />

Marietta area.<br />

COURTESY OF THE U.S. DEPARTMENT OF AGRICULTURE<br />

FOREST SERVICE.<br />

Below: This map of the Cow Run and<br />

Macksburg fields was drafted for John<br />

Bownocker’s 1902 Bulletin 1 of the Ohio<br />

Geological Survey. Macksburg is at the very<br />

<strong>to</strong>p of the map, but is shown as an inset in<br />

the bot<strong>to</strong>m corner.<br />

C H A P T E R F O U R<br />

2 5

Above: Most of the development was south<br />

of Macksburg as shown by this c. 1887<br />

plat map.<br />

COURTESY OF THE OHIO DEPARTMENT OF NATURAL<br />

RESOURCES DIVISION OF GEOLOGICAL SURVEY.<br />

Below: Derricks sprout from the lowlands of<br />

Washing<strong>to</strong>n County. Although this postcard<br />

is labeled for the Marietta area, similar<br />

views are labeled for nearby West Virginia.<br />

It was common for some postcard<br />

pho<strong>to</strong>graphers <strong>to</strong> label the same pho<strong>to</strong> for<br />

several different locations.<br />

COURTESY OF THE AUTHOR.<br />

what was called the 140-foot sand. It was<br />

equivalent <strong>to</strong> the First Cow Run sand<br />

encountered in the southerly Cow Run field.<br />

The best producers in this horizon yielded<br />

around 180 barrels, but most were in the 4- <strong>to</strong><br />

60-barrel range. Here and there, below the<br />

140-foot sand is another thin discontinuous<br />

stringer of sand—the Buell Run—which<br />

occasionally showed a minor amount of oil.<br />

The 300-foot sand is another stratum<br />

containing minor amounts of oil. Below the<br />

300-foot sand is the Peaker sand which has<br />

produced at rates of 40 barrels a day near<br />

Macksburg. These wells were short-lived. The<br />

500-foot sand, 10 <strong>to</strong> 30 feet thick near<br />

Macksburg, was another important horizon.<br />

An 1861 well on the Keith farm initially<br />

produced 100 barrels per day and continued<br />

<strong>to</strong> produce until 1899. Many other wells<br />

tapping this stratum were still producing in<br />

the early 1900s. Discontinuous strands of sand<br />

were also encountered at 700 and 800 feet,<br />

but generally were unproductive in the<br />

Macksburg region. The lowest sand is the<br />

Berea which is pretty continuous throughout<br />

the Macksburg and Cow Run area.<br />

The plays of the 1860s in Noble County<br />

came from Pennsylvanian sands<strong>to</strong>nes marking<br />

the site of former stream and distributary<br />

channels and offshore bars of the clastic delta<br />

complex stretching along the Ohio-<br />

Pennsylvania side of the rising Appalachian<br />

Mountains. These features were constantly<br />

shifting with the rise and fall of the<br />

Pennsylvanian seas and changes in stream<br />

dynamics. This led <strong>to</strong> short discontinuous sand<br />

lenses throughout the Pennsylvanian strata and<br />

the hit and miss potential of any well. Drillers<br />

named the plays based on depth below the<br />

surface. <strong>Oil</strong> horizons might be the Macksburg<br />

140, 300, 700, and 800, referring <strong>to</strong> feet below<br />

the Duck Creek valley. Because of the<br />

meandering of the water courses, Macksburg<br />

O N A H A N D S H A K E : H u m b l e B e g i n n i n g s t o G l o b a l I m p a c t — O h i o ’ s O i l & G a s I n d u s t r y<br />

26

As an example of costs of an early well, F.H. Newell of the Ohio Geological Survey provided the following synopsis in 1888.<br />