8 Hour Stability

8 Hour Stability

8 Hour Stability

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Application Note:<br />

AN_E0637<br />

Key Words<br />

• ICP-AES<br />

• Environmental<br />

Analysis<br />

• SW-846 Method<br />

6010B<br />

• US EPA<br />

• SW-846 Method<br />

3050B<br />

US EPA SW-846 Method 6010B using the IRIS<br />

Intrepid II ICP-AES<br />

1. Introduction<br />

This Application Note describes the use of the Thermo<br />

Electron Corporation IRIS Intrepid II ICP-AES to carry<br />

out SW-846 Method 6010B compliant analysis. The<br />

method is suitable for the determination of 31 elements<br />

in ground waters, TCLP and EP extracts, industrial and<br />

organic wastes, soils, sludges and sediments. This note<br />

provides data showing compliance with each of the<br />

requirements and highlights the integrated system tools<br />

specifically designed to aid compliance.<br />

2. Background<br />

EPA Historical Facts<br />

In 1970, the United States government established the<br />

Environmental Protection Agency (EPA) in response to<br />

growing public demand for cleaner water, air and land.<br />

Prior to this, the national government was not structured<br />

to deal with pollution that caused harm to human health<br />

and degraded the environment. The EPA was tasked with<br />

repairing the damage already done and moving towards<br />

a cleaner environment. Its mission is to protect human<br />

health and to safeguard the natural environment. The<br />

Agency provides leadership in the nation's<br />

environmental science, research, education and<br />

assessment efforts and works closely with other federal<br />

agencies and local government to develop and enforce<br />

regulations under existing environmental law. The<br />

Agency is responsible for researching and setting national<br />

standards for a variety of environmental programs and<br />

delegates the responsibility for issuing permits, and<br />

monitoring and enforcing compliance, to local<br />

government. Where national standards are not met, the<br />

EPA can issue sanctions and take other steps to assist<br />

local government in reaching the desired levels of<br />

environmental quality. The Agency also works with<br />

industries and all levels of government in a wide variety<br />

of voluntary pollution prevention programs and energy<br />

conservation efforts. Its protocols have also been<br />

adopted as the basis for national or local standards in<br />

many countries around the world.<br />

Office of Solid Waste<br />

The EPA's Office of Solid Waste (OSW) regulates all waste<br />

under the Resource Conservation and Recovery Act<br />

(RCRA). The RCRA's goals are to:<br />

1. Protect the public from the hazards of waste disposal<br />

2. Conserve energy and natural resources by recycling and<br />

recovery<br />

3. Reduce or eliminate waste, and<br />

4. Clean up waste, which may have spilled, leaked, or<br />

been improperly disposed of.<br />

The RCRA tightly regulates all hazardous waste from<br />

production to disposal. The RCRA also controls domestic<br />

and industrial waste. Industrial waste is process waste that<br />

comes from a broad range of operations. Some wastes are<br />

managed by other federal agencies or state laws. Examples<br />

of such wastes are animal waste, radioactive waste, and<br />

medical waste.<br />

The EPA publication SW-846, entitled Test Methods for<br />

Evaluating Solid Waste, Physical/Chemical Methods, is the<br />

OSW's official compendium of over 200 analytical and<br />

sampling methods that have been evaluated and approved<br />

for use for analysis relating to the RCRA regulations. SW-<br />

846 functions primarily as a guidance document setting<br />

forth acceptable, although not required, methods for the<br />

regulated and regulatory communities to use in responding<br />

to RCRA-related sampling and analysis requirements. SW-<br />

846 is a multi-volume document that changes over time as<br />

new information and data are developed. It was first issued<br />

by the EPA in 1980 and is currently in its fourth edition.<br />

Advances in analytical instrumentation and techniques are<br />

continually reviewed by the OSW and incorporated into<br />

periodic updates to SW-846 to support changes in the<br />

regulatory program and to improve method performance<br />

and cost effectiveness. To date, the EPA has finalized<br />

Updates I through IIIA of the SW-846 manual, and the<br />

updated and fully integrated manual contains approximately<br />

3500 pages. The Methods Team of OSW has also made<br />

Draft Updates IVA and IVB available for public discussion.<br />

The SW-846 Method 6010B describes the use of ICP-<br />

AES instrumentation for determining a variety of metallic<br />

elements in aqueous and solid media. In draft edition IVA of<br />

November 2000, updated Method 6010C is under<br />

consideration.

Method 6010B (and draft 6010C)<br />

Both methods are broadly similar and provide guidelines<br />

on general laboratory practices such as sample<br />

preparation, instrument setup, calibration of analytes,<br />

and interference correction equations. They also provide<br />

specific rules on various analytical practices that must be<br />

followed, including elements covered, quality control<br />

practices and instrument validation. Since both methods<br />

are well established and readily available in the public<br />

domain they have become widely adopted as templates<br />

for methodologies used by a host of laboratories<br />

undertaking environmental analysis world-wide. The<br />

aim of the protocol is to ensure a consistently high<br />

quality of analytical data by enforcing compliance with a<br />

variety of stringent instrument and analytical<br />

performance checks.<br />

NOTE: Method 6010C, along with all Draft Update IVA SW-846 methods,<br />

may be downloaded from the EPA OSW website:<br />

http://www.epa.gov/epaoswer/hazwaste/test/up4a.htm<br />

3. Experimental<br />

3.1 Equipment<br />

An IRIS Intrepid II Model XDL ICP-AES (Thermo<br />

Electron Corporation, Franklin, Mass., USA) was used<br />

for the analysis of soil and sludge samples. It was fitted<br />

with a dual view optical design - axial view was used for<br />

elements expected at low concentration where the best<br />

sensitivity is required while radial view was used for<br />

elements at higher concentration or for those elements<br />

that suffer from EIE (Easily Ionised Element) interference.<br />

Internal standards were added on-line using the Internal<br />

Standard Mixing Kit (P/N 13670800).<br />

The instrument conditions used for the analysis are<br />

shown in Table 1 below.<br />

PARAMETER VALUE<br />

RF Forward power 1200 watts<br />

Torch Orientation Dual View<br />

Torch Gas Flow 16 L/min<br />

Auxiliary Gas Flow 0.5 L/min<br />

Mixing Chamber Glass Cyclone<br />

Nebulizer Glass Concentric<br />

Nebulizer Gas 0.65 L/min<br />

Sample Pump Winding 3-stop Orange Tygon<br />

Sample Uptake 1.7 mL/min<br />

Purge Gas Argon<br />

Tank Flow 4 L/min<br />

Nozzle Flow 4 L/min<br />

Camera Flow 1 L/min<br />

Table 1. Intrepid II XDL Parameters<br />

Details of the wavelengths and plasma view<br />

orientations used, as well as the internal standards<br />

employed, are shown in Table 2.<br />

ELEMENT WAVELENGTH PLASMA INTERNAL<br />

(nm) VIEW STANDARD<br />

Ag 328.289 Axial Y 361<br />

Al 308.215 Radial Y360<br />

As 189.042 Axial Y224<br />

B 208.959 Axial Y224<br />

Ba 455.403 Radial Y360<br />

Be 313.107 Radial Y360<br />

Ca 317.933 Radial Y360<br />

Cd 214.438 Axial In230<br />

Co 228.616 Axial In230<br />

Cr 205.552 Axial Y224<br />

Cu 324.754 Axial Y361<br />

Fe 271.441 Radial Y360<br />

In 230.606 Axial Int Std<br />

K 766.491 Radial Y360<br />

Li 670.784 Radial Y360<br />

Mg 279.079 Radial Y360<br />

Mn 257.610 Axial Y361<br />

Mo 202.030 Axial Y224<br />

Na 589.592 Radial Y360<br />

Ni 231.604 Axial In230<br />

P 178.287 Axial In230<br />

Pb 220.353 Axial In230<br />

Sb 206.833 Axial Y224<br />

Se 196.090 Axial Y224<br />

Si 251.612 Radial Y360<br />

Sn 189.989 Axial In230<br />

Ti 334.941 Axial Y361<br />

Tl 190.864 Axial In230<br />

V 292.402 Axial Y361<br />

Y 224.306 Axial Int Std<br />

Y 360.073 Radial Int Std<br />

Y 361.105 Axial Int Std<br />

Zn 206.200 Axial In230<br />

Table 2. Wavelengths and Plasma View used.<br />

3.2 Calibration Solutions<br />

Calibration Solutions<br />

High purity reagents were used throughout. Calibration<br />

standards were prepared in 5%v/v HCl and 1%v/v HNO3<br />

from a range of SPEX ICP standards at concentrations<br />

selected to cover the linear range for each element.<br />

Mixed calibration standards were prepared according<br />

to the conditions laid down in Method 6010B.<br />

SOLUTION ELEMENTS<br />

I Be, Cd, Mn, Pb, Se and Zn<br />

II Ba, Co, Cu, Fe and V<br />

III As and Mo<br />

IV Al, Ca, Cr, K, Na, Ni, Li and Sr<br />

V Ag, Mg, Sb and Tl<br />

VI P<br />

A mixture of 20ppm In and 10ppm Y was used as the<br />

internal standard.

Blanks<br />

Two types of blanks are required for the analysis of<br />

samples prepared by any method other than EPA Method<br />

3050B. The calibration blank is used in establishing the<br />

analytical curve and the method blank is used to identify<br />

possible contamination resulting from either the reagents<br />

(acids) or the equipment used during sample processing<br />

including filtration.<br />

The calibration blank is prepared by acidifying<br />

reagent water to the same concentrations of the acids<br />

found in the standards and samples. A sufficient quantity<br />

must be prepared to flush the system between standards<br />

and samples. The calibration blank will also be used for<br />

all initial (ICB) and continuing calibration blank (CCB)<br />

determinations.<br />

The method blank must contain all of the reagents in<br />

the same volumes as used in the processing of the samples.<br />

The method blank must be carried through the complete<br />

preparation procedure and contain the same acid<br />

concentration in the final solution as the sample solution<br />

used for analysis<br />

Check Solutions<br />

The initial calibration verification (ICV) standard is<br />

prepared by combining compatible elements from a<br />

standard source different from that used to prepare the<br />

calibration standard, and at concentration near the<br />

midpoint of the calibration curve. This standard may also<br />

be purchased commercially.<br />

The continuing calibration verification (CCV)<br />

standard is prepared in the same acid matrix using the<br />

same standards used for calibration, at a concentration<br />

near the mid-point of the calibration curve.<br />

The interference check solution (ICS) is prepared to<br />

contain known concentrations of interfering elements that<br />

will provide an adequate test of the correction factors.<br />

The sample is spiked with the elements of interest,<br />

particularly those with known interferences at the 0.5 to 1<br />

mg/L level.<br />

3.3 Method Development<br />

Interelement Corrections<br />

Due to the complex nature of the matrix experienced with<br />

these types of samples, significant interferences from<br />

spectral overlaps can be observed. As part of the method<br />

development process, high purity solutions of the major<br />

matrix elements, such as Al, Ca, Fe, Mg, Si and P, were<br />

checked for their contribution to the signals of other<br />

analyte elements. After the interfering elements were<br />

identified, their solutions were measured and the<br />

instrument software was used to automatically calculate<br />

the appropriate interference correction factors.<br />

Table 3 lists the major interferences found during this<br />

procedure. A dash indicates that no significant interference<br />

was encountered at the wavelength concerned.<br />

ELEMENT WAVELENGTH (nm) INTERFERING ELEMENT<br />

Ag 328.289 Ca, Fe<br />

Al 308.215 -<br />

As 189.042 -<br />

B 208.959 Al, Fe<br />

Ba 455.403 -<br />

Be 313.107 -<br />

Ca 315.887 -<br />

Cd 214.438 Fe<br />

Co 228.616 Fe<br />

Cr 205.552 Fe<br />

Cu 324.754 Ca, Fe<br />

Fe 271.441 -<br />

In 230.606 -<br />

K 766.491 -<br />

Li 670.784 -<br />

Mg 279.079 -<br />

Mn 257.610 Al, Mg<br />

Mo 202.030 -<br />

Na 589.592 -<br />

Ni 231.604 Al, Fe<br />

P 178.287 -<br />

Pb 220.353 Al, Fe<br />

Sb 206.833 Al, Fe<br />

Se 196.090 Al, Fe<br />

Si 251.612 -<br />

Sn 189.989 -<br />

Ti 334.941 -<br />

Tl 190.864 Mg<br />

V 292.402 Fe<br />

Y 224.306 -<br />

Y 360.073 -<br />

Y 361.105 -<br />

Zn 206.200 Fe, Mg<br />

Table 3. Interelement interferences.<br />

Method 6010B states that interference effects must be<br />

evaluated for each individual instrument and the<br />

interelement corrections should be verified daily by<br />

running an ICS. The measured values must be within 20%<br />

for five consecutive days. They must also be verified and<br />

updated every six months or when changes to the<br />

instrumentation have been made (i.e. changing torch or<br />

nebuliser or plasma conditions).<br />

Method Detection Limits (MDL)<br />

Method Detection Limits were established by measuring a<br />

solution containing all the analytes at concentration levels<br />

which are 3 - 5x the published Instrument Detection<br />

Limits for the IRIS Intrepid II. The solution was analysed<br />

ten times on three separate days and the mean of the three<br />

sigma values from all runs was calculated. Table 4 lists the<br />

MDL’s in mg/L measured in the test and Method 6010B<br />

calls for them to be re-confirmed on a quarterly basis.

ELEMENT WAVELENGTH MDL MAXIMUM<br />

(nm) (µg/L) LINEAR RANGE (mg/L)<br />

Ag 328.289 0.5 10<br />

Al 308.215 11.4 1000<br />

As 189.042 2.1 50<br />

B 208.959 2.2 10<br />

Ba 455.403 0.7 50<br />

Be 313.107 0.1 10<br />

Ca 317.933 2.6 1000<br />

Cd 214.438 0.1 20<br />

Co 228.616 0.2 100<br />

Cr 205.552 0.3 50<br />

Cu 324.754 0.5 50<br />

Fe 271.441 52 1000<br />

K 766.491 30 500<br />

Li 670.784 1.0 50<br />

Mg 279.079 40 1000<br />

Mn 257.610 0.1 20<br />

Mo 202.030 0.5 20<br />

Na 589.592 10 200<br />

Ni 231.604 0.4 50<br />

P 178.287 3.2 20<br />

Pb 220.353 2.1 50<br />

Sb 206.833 2.4 50<br />

Se 196.090 2.8 50<br />

Si 251.612 7.2 50<br />

Sn 189.989 1.8 50<br />

Ti 334.941 0.2 20<br />

Tl 190.864 1.6 100<br />

V 292.402 0.6 50<br />

Zn 206.200 0.2 20<br />

Table 4. Wavelengths, Method Detection Limits and Maximum Linear Range.<br />

Linear Concentration Range<br />

The upper limit of the linear dynamic range must be<br />

established for each analyte and instrument configuration.<br />

The upper range limit should result in an observed signal<br />

no more than 10% below the level extrapolated from the<br />

normal calibration curve. This check should be carried<br />

out whenever instrument changes occur and at six<br />

monthly intervals as a minimum.<br />

This evaluation is very important when using interelement<br />

correction since, if the linear range is exceeded for<br />

the interfering element measurement, the calculated<br />

correction factor will be incorrect and the analytical result<br />

will be in error.<br />

For some elements the plasma is viewed in radial<br />

mode using a weaker line to improve the linear range.<br />

This results in less chance of some samples being overrange<br />

so that more accurate data is achieved. Table 4<br />

shows the maximum linear range figures in mg/L.<br />

Background Correction Points<br />

Method 6010B requires that off-peak background<br />

correction is used for trace element determinations. The<br />

background was measured simultaneously by monitoring<br />

the signal in pixels adjacent to the analyte peak position.<br />

The ideal position of background correction points was<br />

determined by examining spectra in subarrays for a<br />

calibration blank, calibration standard and spiked matrix<br />

solution. The points selected for analysis should take into<br />

account any spectral interferences that may be present.<br />

The documented data for all decisions related to<br />

wavelength choice (where different to the EPArecommended<br />

lines), background correction points,<br />

interelement corrections and MDL’s must be kept on file<br />

and be available for review by the data user or auditor.<br />

4. Results and Discussion<br />

4.1 Initial (ICV) and Continuing (CCV) Calibration<br />

Verification<br />

Method 6010B requires that a very strict quality control<br />

procedure is followed to ensure validity of sample data.<br />

Quality control checks are carried out following<br />

instrument calibration, during sample analysis and at the<br />

end of the analytical run. For the sample data to be<br />

acceptable all checks must meet the required criteria.<br />

The instrument was set up using the parameters shown in<br />

Table 1 and allowed to stabilise for 30 minutes prior to<br />

calibration.<br />

Immediately after calibration, an Initial Calibration<br />

Verification (ICV) solution, calibration blank and<br />

Continuing Calibration Verification (CCV) solution were<br />

run. The calibration blank value must be within 3 times<br />

the Method Detection Limit (MDL) while the calibration<br />

verification solution results must be within 10% of their<br />

calibrated value. In addition, the standard deviation for a<br />

minimum of 2 resamples must be less than 5% for the<br />

data to be acceptable. Typical results are shown in Table 5<br />

below.<br />

Analysis of the CCV solution and calibration blank<br />

was then repeated every 10 samples to ensure that the<br />

instrument remained in calibration.<br />

4.2 Interference Check Solutions<br />

Prior to the start of each sample analysis, interference<br />

check solutions were run to verify that the inter-element<br />

correction factors and background correction points were<br />

still valid.<br />

Interference Check Sample A (ICSA) was prepared<br />

containing 500mg/L Al, Ca, Mg and 200mg/L Fe.<br />

Interference Check Solution AB was then prepared by<br />

spiking this solution at concentrations of 0.05 to 1mg/L<br />

for the analyte elements. The values measured for ICSAB<br />

must be within 20% of the true value for the data to be<br />

acceptable. Data is shown in Table 6 below.

ELEMENT ICV (µg/g) CCV (µg/g)<br />

ACTUAL MEASURED ACTUAL MEASURED<br />

Ag 1 0.96 0.5 0.51<br />

Al 200 202 100 99.7<br />

As 1 0.99 0.5 0.48<br />

B 1 0.99 0.5 0.5<br />

Ba 10 10.3 5 4.97<br />

Be 1 1.02 0.5 0.52<br />

Ca 200 201 100 98.8<br />

Cd 1 1.03 0.5 0.49<br />

Co 10 10.5 5 5.02<br />

Cr 10 10.2 5 5.05<br />

Cu 10 9.80 5 4.98<br />

Fe 200 203 100 101<br />

K 100 98.7 50 49.9<br />

Mg 100 101 50 50.5<br />

Mn 10 9.85 5 4.92<br />

Mo 1 1.02 0.5 0.48<br />

Na 100 102 50 51.2<br />

Ni 10 10.1 5 5.10<br />

P 10 10.2 5 5.07<br />

Pb 10 9.93 5 5.04<br />

Sb 1 0.98 0.5 0.48<br />

Se 1 1.05 0.5 0.53<br />

Ti 10 10.1 5 5.02<br />

Tl 1 0.97 0.5 0.48<br />

V 10 10.4 5 4.89<br />

Zn 10 10.1 5 5.02<br />

Table 5. Calibration QC Checks.<br />

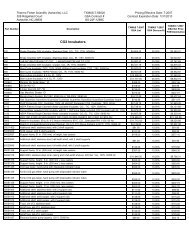

4.3 Correction Factor <strong>Stability</strong> Evaluation<br />

The IRIS Intrepid II XDL spectrometer has a highly<br />

regulated temperature controlled optical system. This<br />

ensures that peak analytical performance is maintained<br />

over extended time periods, despite any fluctuations in the<br />

general laboratory conditions.<br />

An interference correction was set up for Fe on Cd<br />

and then a high purity iron solution was measured over<br />

an 8 hour period in order to assess the amount of drift on<br />

the Cd signal in this time frame. A plot of the data is<br />

shown in Figure 1.<br />

To provide additional evidence of the instrument<br />

stability, a nominal 100 ppb multielement standard was<br />

analysed over an 8 hour period, without any calibration<br />

updates. The plots are shown in Figure 2 and illustrate the<br />

inherent stability of the system.<br />

ELEMENT ICSA ICSAB TARGET VALUE %<br />

(µg/L) (µg/L) (µg/L) RECOVERY<br />

Ag < 0.5 98.7 100 98.7<br />

As -1.3 100.7 100 100.7<br />

B < 2 499 500 99.8<br />

Ba < 0.7 486 500 97.2<br />

Be < 0.1 495 500 99.0<br />

Cd < 0.1 103 100 103<br />

Co < 0.2 489 500 97.8<br />

Cr < 0.3 476 500 95.2<br />

Cu < 0.5 478 500 95.6<br />

Mn < 0.1 512 500 102<br />

Mo < 0.5 478 500 95.6<br />

Ni < 0.4 952 1000 95.2<br />

P < 3 475 500 95<br />

Pb < 2 48.9 50 97.8<br />

Sb < 2 503 500 101<br />

Se < 3 58 50 116<br />

Si < 7 47 50 94<br />

Ti < 0.2 507 500 101<br />

Tl < 2 88.5 100 88.5<br />

V < 0.6 487 500 97.4<br />

Zn < 0.2 1012 1000 101<br />

Table 6. Results for Interference Check Solutions.<br />

4.4 Sample Results<br />

After the successful analysis of the specified quality<br />

control solutions, the actual sample analysis sequence can<br />

begin. With the exception of groundwater samples, all<br />

aqueous and solid matrices require acid digestion prior to<br />

analysis. Recommended dissolution procedures for real<br />

samples are given in EPA Method 3050B or 3051A (the<br />

latter being a microwave-assisted version of the former).<br />

Groundwater samples that have been pre-filtered and<br />

acidified do not need acid digestion.<br />

It is general practice to include at least one Laboratory<br />

Control Sample (LCS) in each run, the LCS normally<br />

being a Standard Reference Material with a similar matrix<br />

to the samples being analysed. In this particular analysis, a<br />

sample of Buffalo River Sediment (NBS SRM2704) was<br />

prepared and used as the LCS.<br />

This sample can also be prepared and analysed in<br />

duplicate, at least once per analysis, in order to check for<br />

contamination problems. The sample was also spiked and<br />

analysed to monitor spike recoveries.<br />

Method 6010B states that duplicate samples must<br />

agree within 20% of each other and spiked samples must<br />

be recovered within 25% of the actual value.

Concentration (ug/L)<br />

110<br />

105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

10:38<br />

11:15<br />

11:44<br />

8 <strong>Hour</strong> Run, drift of Corrected Cadmium with Iron IEC<br />

12:16<br />

12:48<br />

13:14<br />

13:40<br />

EPA Acceptable Range<br />

EPA Acceptable Range<br />

13:57<br />

8 <strong>Hour</strong> <strong>Stability</strong><br />

1 21 41 61 81 101 121<br />

Sample number<br />

ELEMENT MEASURED CONCENTRATION CERTIFIED VALUE<br />

As 23.1µg/g 23.4+/- 0.8<br />

Ba 407µg/g 414 +/- 12<br />

Ca 2.55% 2.60 +/- 0.03<br />

Cd 3.50µg/g 3.45 +/- 0.22<br />

Co 14.3µg/g 14 +/- 0.6<br />

Cr 132µg/g 135 +/- 5<br />

Cu 100.2µg/g 98.6 +/- 5.0<br />

Fe 4.03% 4.11 +/- 0.10<br />

K 2.02% 2.00 +/- 0.04<br />

Mg 1.21% 1.20 +/- 0.02<br />

Mn 547µg/g 555 +/- 19<br />

Na 0.53% 0.547 +/- 0.014<br />

Ni 43.8µg/g 44.1 +/- 3.0<br />

Pb 163µg/g 161 +/- 17<br />

Sb 3.61µg/g 3.79 +/- 0.15<br />

Ti 0.46% 0.457 +/- 0.018<br />

V 93µg/g 95 +/- 4<br />

Zn 440µg/g 438 +/- 12<br />

Table 7. NBS 2704 Buffalo River Sediment Data<br />

14:25<br />

15:12<br />

15:40<br />

15:55<br />

16:25<br />

16:50<br />

17:18<br />

17:42<br />

18:00<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

-0.5 -<br />

-1 -<br />

-1.5 -<br />

-2 -<br />

PPB<br />

As1890<br />

Ba4554<br />

Cd2288<br />

Pb2203<br />

Se1960<br />

Zn2138<br />

Figure 1. <strong>Stability</strong> of<br />

the Fe interelement<br />

correction factor for<br />

Cd<br />

Figure 2. <strong>Stability</strong> of a<br />

100ppb multielement<br />

standard over an 8<br />

hour period<br />

Table 7 compares the measured and certified results<br />

for the SRM2704 Buffalo River Sediment sample,<br />

demonstrating the excellent agreement between them.

Table 8 shows the results for a duplicate analysis test<br />

with the LCS sample. Agreement between duplicates is<br />

generally within 1%, well within the EPA limit of 20%.<br />

ELEMENT ANALYSIS 1 ANALYSIS 2 % DIFFERENCE<br />

As 23.1µg/g 23.3µg/g 0.8<br />

Ba 407µg/g 403µg/g 1.0<br />

Ca 2.55% 2.54% 0.4<br />

Cd 3.50µg/g 3.46µg/g 1.1<br />

Co 14.3µg/g 14.4µg/g 0.7<br />

Cr 132µg/g 131µg/g 0.8<br />

Cu 100.2µg/g 101µg/g 0.8<br />

Fe 4.03% 4.04% 0.3<br />

K 2.02% 2.03% 0.6<br />

Mg 1.21% 1.20% 0.3<br />

Mn 547µg/g 543µg/g 0.8<br />

Na 0.53% 0.54% 1.8<br />

Ni 43.8µg/g 44.1µg/g 0.7<br />

Pb 163µg/g 163µg/g 0.2<br />

Sb 3.61µg/g 3.65µg/g 1.1<br />

Ti 0.46% 0.46% 0.4<br />

V 93.0µg/g 92.3µg/g 0.8<br />

Zn 440µg/g 435µg/g 1.1<br />

Table 8. NBS 2704 Buffalo River Sediment Duplicate Analysis Test<br />

Table 9 shows the recoveries from spiked samples of<br />

the LCS, again all well within the EPA 25% limit.<br />

ELEMENT CERTIFIED VALUE SPIKE CONC MEASURED VALUE % REC<br />

www.thermo.com/elemental<br />

µg/L µg/L µg/L<br />

As 230 50 276 92<br />

Ba 4140 100 4234 94<br />

Cd 34.5 10 43.6 91<br />

Co 140 10 151 110<br />

Cr 1350 50 1402 104<br />

Cu 986 50 1033 94<br />

Mn 5550 100 5652 102<br />

Ni 441 10 450 90<br />

Pb 1610 50 1656 92<br />

Sb 37.9 10 47.0 91<br />

V 950 50 1004 108<br />

Zn 4380 100 4482 102<br />

Table 9. NBS 2704 Buffalo River Sediment Spike Sample Recovery Data<br />

In order to check that the method works for different<br />

sample matrices, a reference sample of a sewage sludge<br />

(BCR146) was analysed using exactly the same procedure.<br />

Table 10 compares the measured and certified results for<br />

the sediment sample, demonstrating the excellent<br />

agreement. Values in brackets are advisory figures only.<br />

USA: 5225 Verona Road<br />

Madison, WI 53711-4495<br />

Tel: +1 800 201 8132, +1 608 276 6100<br />

Fax: +1 608 273 5046<br />

Email: spectroscopy@thermo.com<br />

ELEMENT MEASURED CONCENTRATION CERTIFIED VALUE<br />

Ca 10.2% (10.14%)<br />

Cd 75.8µg/g 77.7 +/- 2.6<br />

Co 11.9µg/g 11.8 +/- 0.7<br />

Cu 928µg/g 934 +/- 24<br />

Fe 1.80% (1.86%)<br />

K 0.49% (0.48%)<br />

Mg 2.01% (1.99%)<br />

Mn 570µg/g 588 +/- 24<br />

Na 0.21% (0.22%)<br />

Ni 276µg/g 280 +/- 18<br />

P 2.52% (2.58%)<br />

Pb 1260µg/g 1270 +/- 28<br />

Zn 4040µg/g 4059 +/- 90<br />

Table 10. BCR146 Sewage Sludge Data<br />

5. Conclusions<br />

The IRIS Intrepid II demonstrates SW-846 Method 6010B<br />

compliant analysis for a range of sample types and easily<br />

copes with the stringent interference checks and AQC<br />

requirements stipulated for use in this method.<br />

The IRIS Intrepid II is the latest generation of IRIS<br />

ICP Spectrometers from Thermo Electron. It incorporates<br />

a new design of the exclusive charge injection device<br />

(CID) detector housed in a highly regulated optical<br />

system. The result of these product developments is an<br />

instrument that is capable of providing extremely low<br />

detection limits and excellent long term stability. This<br />

makes the IRIS Intrepid II ideally suited for cost-effective<br />

elemental analysis in the environmental field.<br />

References<br />

USEPA SW-846 Method 3050B, Revision 2, December 1996.<br />

USEPA SW-846 Method 3051A, Revision 1, January 1998.<br />

USEPA SW-846 Method 6010B, Revision 2, December 1996.<br />

USEPA SW-846 Method 6010C, Revision 3, November 2000.<br />

UK: 19 Mercers Row<br />

Cambridge, CB5 8BZ, UK<br />

Tel: +44 (0)1223 345410<br />

Fax: +44 (0)1223 345411<br />

Email: spectroscopy.uk@thermo.com<br />

Switzerland: En Vallaire Ouest C<br />

case postale, CH-1024, Ecublens<br />

Tel: +41 (0)21 694 71 11<br />

Fax: +41 (0)21 694 71 12<br />

Email: spectroscopy.ch@thermo.com<br />

Thermo Electron Corporation<br />

has direct subsidiary offices in<br />

North America, Europe and<br />

Japan. To complement these<br />

direct subsidiaries, we maintain<br />

a network of representative<br />

organizations throughout the<br />

world. Use this reference list or<br />

visit our Web site to locate the<br />

representative nearest you.<br />

Australia<br />

Tel: +61 (0)2 9898 1244<br />

Austria<br />

Tel: +43 (0)1 333 50 34 0<br />

Belgium<br />

Tel: +32 2482 3030<br />

Canada<br />

Tel: +1 905 890 1034<br />

China<br />

Thermo ARL:<br />

Tel: +86 10 6833 6715<br />

Thermo Elemental:<br />

Tel: +86 10 6592 0232<br />

Thermo Nicolet:<br />

Tel: +86 10 6597 3388 ext 2912<br />

France<br />

Tel: +33 (0)1 39 30 53 00<br />

Germany<br />

Tel: +49 (0)6102 3671 0<br />

Italy<br />

Tel: +39 02 6601 6351<br />

Japan<br />

Thermo Elemental:<br />

Tel: +81 774 201245<br />

Thermo Nicolet:<br />

Tel: +81 45 450 1112<br />

Netherlands<br />

Tel: +31 76 5724840<br />

Nordic<br />

Thermo Nicolet:<br />

Tel: +358 9 3291 00<br />

Thermo ARL:<br />

Tel: +46 (0)8 556 468 31<br />

South Africa<br />

Tel: +27 (0) 11 570 1840<br />

Spain<br />

Tel: +34 (91) 657 49 30<br />

©2003 Thermo Electron Corp.<br />

All rights reserved worldwide.<br />

We make no warranties,<br />

expressed or implied, in<br />

this product summary, and<br />

information is subject to<br />

change without notice.<br />

All product and company<br />

names are property of their<br />

respective owners.<br />

AN_E0637 06/03