8 Hour Stability

8 Hour Stability

8 Hour Stability

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Method 6010B (and draft 6010C)<br />

Both methods are broadly similar and provide guidelines<br />

on general laboratory practices such as sample<br />

preparation, instrument setup, calibration of analytes,<br />

and interference correction equations. They also provide<br />

specific rules on various analytical practices that must be<br />

followed, including elements covered, quality control<br />

practices and instrument validation. Since both methods<br />

are well established and readily available in the public<br />

domain they have become widely adopted as templates<br />

for methodologies used by a host of laboratories<br />

undertaking environmental analysis world-wide. The<br />

aim of the protocol is to ensure a consistently high<br />

quality of analytical data by enforcing compliance with a<br />

variety of stringent instrument and analytical<br />

performance checks.<br />

NOTE: Method 6010C, along with all Draft Update IVA SW-846 methods,<br />

may be downloaded from the EPA OSW website:<br />

http://www.epa.gov/epaoswer/hazwaste/test/up4a.htm<br />

3. Experimental<br />

3.1 Equipment<br />

An IRIS Intrepid II Model XDL ICP-AES (Thermo<br />

Electron Corporation, Franklin, Mass., USA) was used<br />

for the analysis of soil and sludge samples. It was fitted<br />

with a dual view optical design - axial view was used for<br />

elements expected at low concentration where the best<br />

sensitivity is required while radial view was used for<br />

elements at higher concentration or for those elements<br />

that suffer from EIE (Easily Ionised Element) interference.<br />

Internal standards were added on-line using the Internal<br />

Standard Mixing Kit (P/N 13670800).<br />

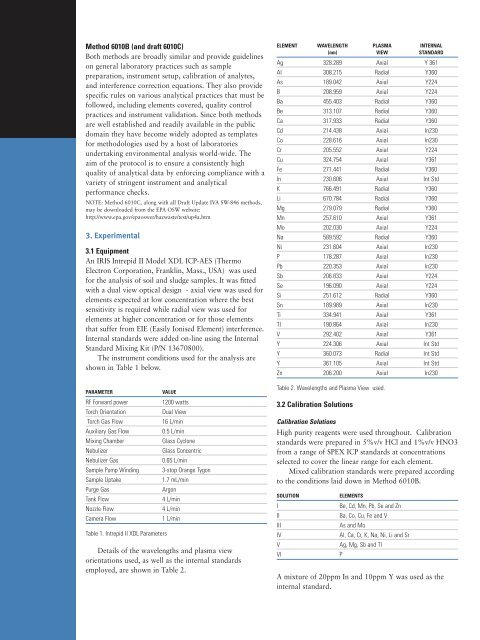

The instrument conditions used for the analysis are<br />

shown in Table 1 below.<br />

PARAMETER VALUE<br />

RF Forward power 1200 watts<br />

Torch Orientation Dual View<br />

Torch Gas Flow 16 L/min<br />

Auxiliary Gas Flow 0.5 L/min<br />

Mixing Chamber Glass Cyclone<br />

Nebulizer Glass Concentric<br />

Nebulizer Gas 0.65 L/min<br />

Sample Pump Winding 3-stop Orange Tygon<br />

Sample Uptake 1.7 mL/min<br />

Purge Gas Argon<br />

Tank Flow 4 L/min<br />

Nozzle Flow 4 L/min<br />

Camera Flow 1 L/min<br />

Table 1. Intrepid II XDL Parameters<br />

Details of the wavelengths and plasma view<br />

orientations used, as well as the internal standards<br />

employed, are shown in Table 2.<br />

ELEMENT WAVELENGTH PLASMA INTERNAL<br />

(nm) VIEW STANDARD<br />

Ag 328.289 Axial Y 361<br />

Al 308.215 Radial Y360<br />

As 189.042 Axial Y224<br />

B 208.959 Axial Y224<br />

Ba 455.403 Radial Y360<br />

Be 313.107 Radial Y360<br />

Ca 317.933 Radial Y360<br />

Cd 214.438 Axial In230<br />

Co 228.616 Axial In230<br />

Cr 205.552 Axial Y224<br />

Cu 324.754 Axial Y361<br />

Fe 271.441 Radial Y360<br />

In 230.606 Axial Int Std<br />

K 766.491 Radial Y360<br />

Li 670.784 Radial Y360<br />

Mg 279.079 Radial Y360<br />

Mn 257.610 Axial Y361<br />

Mo 202.030 Axial Y224<br />

Na 589.592 Radial Y360<br />

Ni 231.604 Axial In230<br />

P 178.287 Axial In230<br />

Pb 220.353 Axial In230<br />

Sb 206.833 Axial Y224<br />

Se 196.090 Axial Y224<br />

Si 251.612 Radial Y360<br />

Sn 189.989 Axial In230<br />

Ti 334.941 Axial Y361<br />

Tl 190.864 Axial In230<br />

V 292.402 Axial Y361<br />

Y 224.306 Axial Int Std<br />

Y 360.073 Radial Int Std<br />

Y 361.105 Axial Int Std<br />

Zn 206.200 Axial In230<br />

Table 2. Wavelengths and Plasma View used.<br />

3.2 Calibration Solutions<br />

Calibration Solutions<br />

High purity reagents were used throughout. Calibration<br />

standards were prepared in 5%v/v HCl and 1%v/v HNO3<br />

from a range of SPEX ICP standards at concentrations<br />

selected to cover the linear range for each element.<br />

Mixed calibration standards were prepared according<br />

to the conditions laid down in Method 6010B.<br />

SOLUTION ELEMENTS<br />

I Be, Cd, Mn, Pb, Se and Zn<br />

II Ba, Co, Cu, Fe and V<br />

III As and Mo<br />

IV Al, Ca, Cr, K, Na, Ni, Li and Sr<br />

V Ag, Mg, Sb and Tl<br />

VI P<br />

A mixture of 20ppm In and 10ppm Y was used as the<br />

internal standard.