8 Hour Stability

8 Hour Stability

8 Hour Stability

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

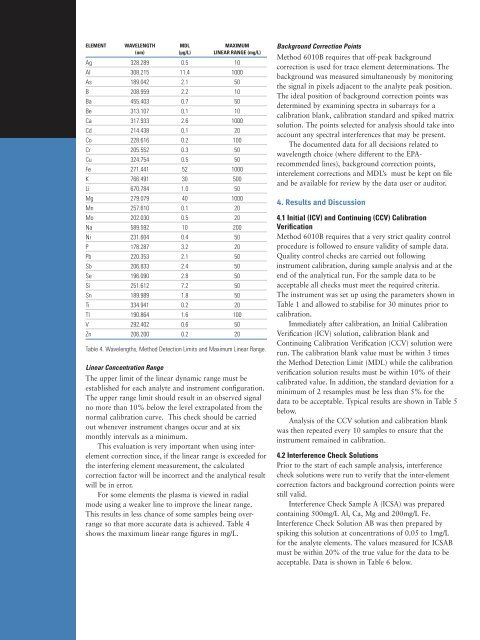

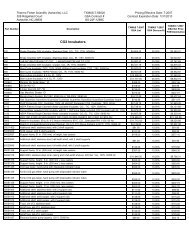

ELEMENT WAVELENGTH MDL MAXIMUM<br />

(nm) (µg/L) LINEAR RANGE (mg/L)<br />

Ag 328.289 0.5 10<br />

Al 308.215 11.4 1000<br />

As 189.042 2.1 50<br />

B 208.959 2.2 10<br />

Ba 455.403 0.7 50<br />

Be 313.107 0.1 10<br />

Ca 317.933 2.6 1000<br />

Cd 214.438 0.1 20<br />

Co 228.616 0.2 100<br />

Cr 205.552 0.3 50<br />

Cu 324.754 0.5 50<br />

Fe 271.441 52 1000<br />

K 766.491 30 500<br />

Li 670.784 1.0 50<br />

Mg 279.079 40 1000<br />

Mn 257.610 0.1 20<br />

Mo 202.030 0.5 20<br />

Na 589.592 10 200<br />

Ni 231.604 0.4 50<br />

P 178.287 3.2 20<br />

Pb 220.353 2.1 50<br />

Sb 206.833 2.4 50<br />

Se 196.090 2.8 50<br />

Si 251.612 7.2 50<br />

Sn 189.989 1.8 50<br />

Ti 334.941 0.2 20<br />

Tl 190.864 1.6 100<br />

V 292.402 0.6 50<br />

Zn 206.200 0.2 20<br />

Table 4. Wavelengths, Method Detection Limits and Maximum Linear Range.<br />

Linear Concentration Range<br />

The upper limit of the linear dynamic range must be<br />

established for each analyte and instrument configuration.<br />

The upper range limit should result in an observed signal<br />

no more than 10% below the level extrapolated from the<br />

normal calibration curve. This check should be carried<br />

out whenever instrument changes occur and at six<br />

monthly intervals as a minimum.<br />

This evaluation is very important when using interelement<br />

correction since, if the linear range is exceeded for<br />

the interfering element measurement, the calculated<br />

correction factor will be incorrect and the analytical result<br />

will be in error.<br />

For some elements the plasma is viewed in radial<br />

mode using a weaker line to improve the linear range.<br />

This results in less chance of some samples being overrange<br />

so that more accurate data is achieved. Table 4<br />

shows the maximum linear range figures in mg/L.<br />

Background Correction Points<br />

Method 6010B requires that off-peak background<br />

correction is used for trace element determinations. The<br />

background was measured simultaneously by monitoring<br />

the signal in pixels adjacent to the analyte peak position.<br />

The ideal position of background correction points was<br />

determined by examining spectra in subarrays for a<br />

calibration blank, calibration standard and spiked matrix<br />

solution. The points selected for analysis should take into<br />

account any spectral interferences that may be present.<br />

The documented data for all decisions related to<br />

wavelength choice (where different to the EPArecommended<br />

lines), background correction points,<br />

interelement corrections and MDL’s must be kept on file<br />

and be available for review by the data user or auditor.<br />

4. Results and Discussion<br />

4.1 Initial (ICV) and Continuing (CCV) Calibration<br />

Verification<br />

Method 6010B requires that a very strict quality control<br />

procedure is followed to ensure validity of sample data.<br />

Quality control checks are carried out following<br />

instrument calibration, during sample analysis and at the<br />

end of the analytical run. For the sample data to be<br />

acceptable all checks must meet the required criteria.<br />

The instrument was set up using the parameters shown in<br />

Table 1 and allowed to stabilise for 30 minutes prior to<br />

calibration.<br />

Immediately after calibration, an Initial Calibration<br />

Verification (ICV) solution, calibration blank and<br />

Continuing Calibration Verification (CCV) solution were<br />

run. The calibration blank value must be within 3 times<br />

the Method Detection Limit (MDL) while the calibration<br />

verification solution results must be within 10% of their<br />

calibrated value. In addition, the standard deviation for a<br />

minimum of 2 resamples must be less than 5% for the<br />

data to be acceptable. Typical results are shown in Table 5<br />

below.<br />

Analysis of the CCV solution and calibration blank<br />

was then repeated every 10 samples to ensure that the<br />

instrument remained in calibration.<br />

4.2 Interference Check Solutions<br />

Prior to the start of each sample analysis, interference<br />

check solutions were run to verify that the inter-element<br />

correction factors and background correction points were<br />

still valid.<br />

Interference Check Sample A (ICSA) was prepared<br />

containing 500mg/L Al, Ca, Mg and 200mg/L Fe.<br />

Interference Check Solution AB was then prepared by<br />

spiking this solution at concentrations of 0.05 to 1mg/L<br />

for the analyte elements. The values measured for ICSAB<br />

must be within 20% of the true value for the data to be<br />

acceptable. Data is shown in Table 6 below.