8 Hour Stability

8 Hour Stability

8 Hour Stability

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Blanks<br />

Two types of blanks are required for the analysis of<br />

samples prepared by any method other than EPA Method<br />

3050B. The calibration blank is used in establishing the<br />

analytical curve and the method blank is used to identify<br />

possible contamination resulting from either the reagents<br />

(acids) or the equipment used during sample processing<br />

including filtration.<br />

The calibration blank is prepared by acidifying<br />

reagent water to the same concentrations of the acids<br />

found in the standards and samples. A sufficient quantity<br />

must be prepared to flush the system between standards<br />

and samples. The calibration blank will also be used for<br />

all initial (ICB) and continuing calibration blank (CCB)<br />

determinations.<br />

The method blank must contain all of the reagents in<br />

the same volumes as used in the processing of the samples.<br />

The method blank must be carried through the complete<br />

preparation procedure and contain the same acid<br />

concentration in the final solution as the sample solution<br />

used for analysis<br />

Check Solutions<br />

The initial calibration verification (ICV) standard is<br />

prepared by combining compatible elements from a<br />

standard source different from that used to prepare the<br />

calibration standard, and at concentration near the<br />

midpoint of the calibration curve. This standard may also<br />

be purchased commercially.<br />

The continuing calibration verification (CCV)<br />

standard is prepared in the same acid matrix using the<br />

same standards used for calibration, at a concentration<br />

near the mid-point of the calibration curve.<br />

The interference check solution (ICS) is prepared to<br />

contain known concentrations of interfering elements that<br />

will provide an adequate test of the correction factors.<br />

The sample is spiked with the elements of interest,<br />

particularly those with known interferences at the 0.5 to 1<br />

mg/L level.<br />

3.3 Method Development<br />

Interelement Corrections<br />

Due to the complex nature of the matrix experienced with<br />

these types of samples, significant interferences from<br />

spectral overlaps can be observed. As part of the method<br />

development process, high purity solutions of the major<br />

matrix elements, such as Al, Ca, Fe, Mg, Si and P, were<br />

checked for their contribution to the signals of other<br />

analyte elements. After the interfering elements were<br />

identified, their solutions were measured and the<br />

instrument software was used to automatically calculate<br />

the appropriate interference correction factors.<br />

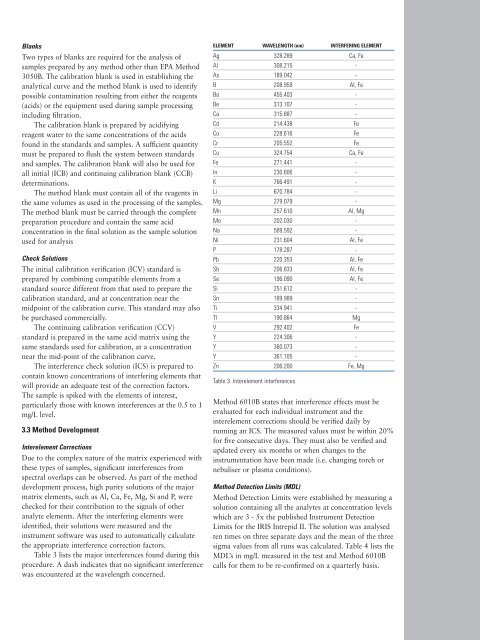

Table 3 lists the major interferences found during this<br />

procedure. A dash indicates that no significant interference<br />

was encountered at the wavelength concerned.<br />

ELEMENT WAVELENGTH (nm) INTERFERING ELEMENT<br />

Ag 328.289 Ca, Fe<br />

Al 308.215 -<br />

As 189.042 -<br />

B 208.959 Al, Fe<br />

Ba 455.403 -<br />

Be 313.107 -<br />

Ca 315.887 -<br />

Cd 214.438 Fe<br />

Co 228.616 Fe<br />

Cr 205.552 Fe<br />

Cu 324.754 Ca, Fe<br />

Fe 271.441 -<br />

In 230.606 -<br />

K 766.491 -<br />

Li 670.784 -<br />

Mg 279.079 -<br />

Mn 257.610 Al, Mg<br />

Mo 202.030 -<br />

Na 589.592 -<br />

Ni 231.604 Al, Fe<br />

P 178.287 -<br />

Pb 220.353 Al, Fe<br />

Sb 206.833 Al, Fe<br />

Se 196.090 Al, Fe<br />

Si 251.612 -<br />

Sn 189.989 -<br />

Ti 334.941 -<br />

Tl 190.864 Mg<br />

V 292.402 Fe<br />

Y 224.306 -<br />

Y 360.073 -<br />

Y 361.105 -<br />

Zn 206.200 Fe, Mg<br />

Table 3. Interelement interferences.<br />

Method 6010B states that interference effects must be<br />

evaluated for each individual instrument and the<br />

interelement corrections should be verified daily by<br />

running an ICS. The measured values must be within 20%<br />

for five consecutive days. They must also be verified and<br />

updated every six months or when changes to the<br />

instrumentation have been made (i.e. changing torch or<br />

nebuliser or plasma conditions).<br />

Method Detection Limits (MDL)<br />

Method Detection Limits were established by measuring a<br />

solution containing all the analytes at concentration levels<br />

which are 3 - 5x the published Instrument Detection<br />

Limits for the IRIS Intrepid II. The solution was analysed<br />

ten times on three separate days and the mean of the three<br />

sigma values from all runs was calculated. Table 4 lists the<br />

MDL’s in mg/L measured in the test and Method 6010B<br />

calls for them to be re-confirmed on a quarterly basis.