Jeweller - May 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

so you don’t put the environment, the public or your employees at risk.”<br />

Morris & Watson, too, holds environmental sustainability is a core value. “Every<br />

green initiative we have undertaken over the years has repaid us many times over<br />

via reduced production costs and higher yield returns,” says George. “For example<br />

our filter press and water recycle programs have ensured substantial reduction<br />

in water rates and acid removal costs along with a double check on any precious<br />

metal content of the spent acid.”<br />

Chemgold takes an extra step, ensuring all slurry waste is filtered so it doesn’t end<br />

up in the sewerage system. This waste is then collected and treated by a specialist<br />

environmentally friendly company.<br />

Across both the casting and refining industries, reducing packaging waste with<br />

biodegradable options is becoming mainstream, as is becoming energy conscious<br />

by upgrading to newer, more efficient plants powered by renewables like solar.<br />

Botha says there is an “emphasis on environmentally friendly precious metal that is<br />

responsibly sourced from guaranteed conflict free areas.”<br />

To ensure its supply chain is as ethical as possible, Botha says that Palloys sources<br />

from its sister company, ABC Refinery, which is accredited by the London Bullion<br />

Market Association (LBMA) and the Shanghai Gold Exchange (SGE). “This has a<br />

major benefit that no other precious metals group in Australia can offer,” says<br />

Botha. “All Palloys precious metals comply with the strictest of sourcing controls<br />

that guarantee our metals are responsibly sourced and conflict free.”<br />

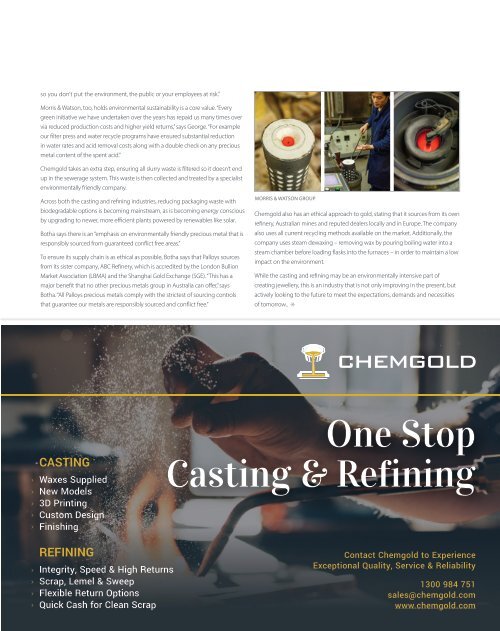

MORRIS & WATSON GROUP<br />

Chemgold also has an ethical approach to gold, stating that it sources from its own<br />

refinery, Australian mines and reputed dealers locally and in Europe. The company<br />

also uses all current recycling methods available on the market. Additionally, the<br />

company uses steam dewaxing – removing wax by pouring boiling water into a<br />

steam chamber before loading flasks into the furnaces – in order to maintain a low<br />

impact on the environment.<br />

While the casting and refining may be an environmentally intensive part of<br />

creating jewellery, this is an industry that is not only improving in the present, but<br />

actively looking to the future to meet the expectations, demands and necessities<br />

of tomorrow.. i<br />

CASTING<br />

Waxes Supplied<br />

New Models<br />

3D Printing<br />

Custom Design<br />

Finishing<br />

One Stop<br />

Casting & Refining<br />

REFINING<br />

Integrity, Speed & High Returns<br />

Scrap, Lemel & Sweep<br />

Flexible Return Options<br />

Quick Cash for Clean Scrap<br />

Contact Chemgold to Experience<br />

Exceptional Quality, Service & Reliability<br />

1300 984 751<br />

sales@chemgold.com<br />

www.chemgold.com