You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Aerial<br />

Advantage<br />

Softwashing drones built by<br />

North Carolina-based Lucid Drone<br />

Technologies promise to make<br />

businesses more efficient<br />

BY DREW RUBLE<br />

In a recent Forbes magazine article<br />

titled “The Future of Work: Humans<br />

+ Gigs + Robots are the New Blended<br />

Workforce,” author Jeanne Meister explored<br />

how it’s “humans AND machines<br />

who comprise the new blended workforce,<br />

not humans VS. machines.”<br />

Meister highlights the new category<br />

of jobs emerging that blend blue collar<br />

work with digital know-how, which she<br />

defined as “New Collar jobs.”<br />

“What is needed” she says, “is the<br />

ability to re-imagine how [businesses]…<br />

invest in learning and development…<br />

and nurture a new blended workforce.”<br />

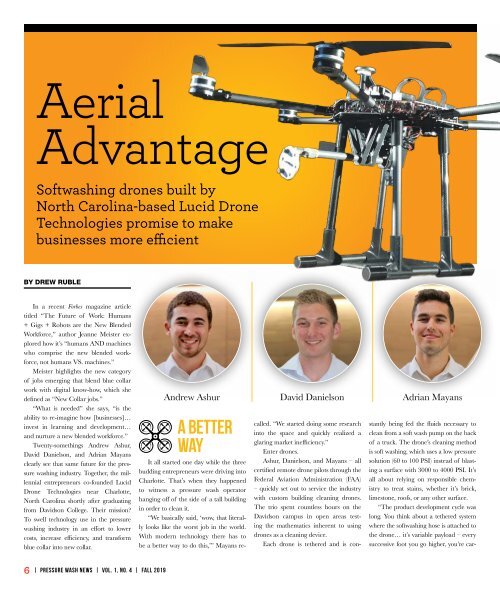

Twenty-somethings Andrew Ashur,<br />

David Danielson, and Adrian Mayans<br />

clearly see that same future for the pressure<br />

washing industry. Together, the millennial<br />

entrepreneurs co-founded Lucid<br />

Drone Technologies near Charlotte,<br />

North Carolina shortly after graduating<br />

from Davidson College. Their mission?<br />

To swell technology use in the pressure<br />

washing industry in an effort to lower<br />

costs, increase efficiency, and transform<br />

blue collar into new collar.<br />

Andrew Ashur David Danielson Adrian Mayans<br />

A BETTER<br />

WAY<br />

It all started one day while the three<br />

budding entrepreneurs were driving into<br />

Charlotte. That’s when they happened<br />

to witness a pressure wash operator<br />

hanging off of the side of a tall building<br />

in order to clean it.<br />

“We basically said, ‘wow, that literally<br />

looks like the worst job in the world.<br />

With modern technology there has to<br />

be a better way to do this,’” Mayans recalled.<br />

“We started doing some research<br />

into the space and quickly realized a<br />

glaring market inefficiency.”<br />

Enter drones.<br />

Ashur, Danielson, and Mayans – all<br />

certified remote drone pilots through the<br />

Federal Aviation Administration (FAA)<br />

– quickly set out to service the industry<br />

with custom building cleaning drones.<br />

The trio spent countless hours on the<br />

Davidson campus in open areas testing<br />

the mathematics inherent to using<br />

drones as a cleaning device.<br />

Each drone is tethered and is constantly<br />

being fed the fluids necessary to<br />

clean from a soft wash pump on the back<br />

of a truck. The drone’s cleaning method<br />

is soft washing, which uses a low pressure<br />

solution (60 to 100 PSI) instead of blasting<br />

a surface with 3000 to 4000 PSI. It’s<br />

all about relying on responsible chemistry<br />

to treat stains, whether it’s brick,<br />

limestone, roofs, or any other surface.<br />

“The product development cycle was<br />

long. You think about a tethered system<br />

where the softwashing hose is attached to<br />

the drone… it’s variable payload – every<br />

successive foot you go higher, you’re car-<br />

6 | PRESSURE WASH NEWS | VOL. 1, NO. 4 | FALL <strong>2019</strong>