Rockford Systems Control Systems for Presses Catalog

Catalog for control systems for mechanical power presses and press brakes, and hydraulic power presses and press brakes. These control systems are designed and built to comply with applicable OSHA regulations and ANSI standards. The catalog goes into detail about the features of the systems, and describes the different options available to update or replace existing control systems. This catalog also includes spring-loaded turnover bars, palm button assemblies, danger signs, and a section with helpful references. The catalog is divided into sections that offer control systems and components for: - Full-Revolution-Clutch Presses - Part-Revolution-Clutch Presses and Press Brakes - Hydraulic Presses and Press Brakes - Press Automation Control

Catalog for control systems for mechanical power presses and press brakes, and hydraulic power presses and press brakes. These control systems are designed and built to comply with applicable OSHA regulations and ANSI standards. The catalog goes into detail about the features of the systems, and describes the different options available to update or replace existing control systems. This catalog also includes spring-loaded turnover bars, palm button assemblies, danger signs, and a section with helpful references.

The catalog is divided into sections that offer control systems and components for:

- Full-Revolution-Clutch Presses

- Part-Revolution-Clutch Presses and Press Brakes

- Hydraulic Presses and Press Brakes

- Press Automation Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SSC-3000 EXPANDABLE OPTIONS (CONTINUED)<br />

DIE PROTECTION CARD<br />

Part No. FTL-321<br />

The 8-Input Die Protection Card is designed to provide user-programmable inputs that monitor static or cyclic events during the press stroke. Up to<br />

three 8-Input Die Protection Cards can be used <strong>for</strong> a total of 24 inputs. The 24-V DC inputs have individual jumpers that set each input to current<br />

sinking or sourcing. All inputs have depluggable terminal strips with LED indicators <strong>for</strong> easy installation and maintenance.<br />

The die protection inputs can be used <strong>for</strong> equipment monitoring, die protection, or other user-defined functions. Five (5) parameters can be<br />

programmed <strong>for</strong> each input: logic, stop type, open angle, close angle, and fault message. Ten (10) user-defined messages exist at the end of the<br />

user-programmable fault list. These ten messages can be edited by the user via the programmable options in the main program screen.<br />

ANGLE DISPLAY CARD<br />

Part No. FTL-323<br />

The Angle Display Card is used in conjunction with the crankshaft angle display described below. The crankshaft angle display unit must be<br />

purchased in addition to the angle display card.<br />

CRANKSHAFT ANGLE DISPLAY UNIT<br />

Part No. FTL-054<br />

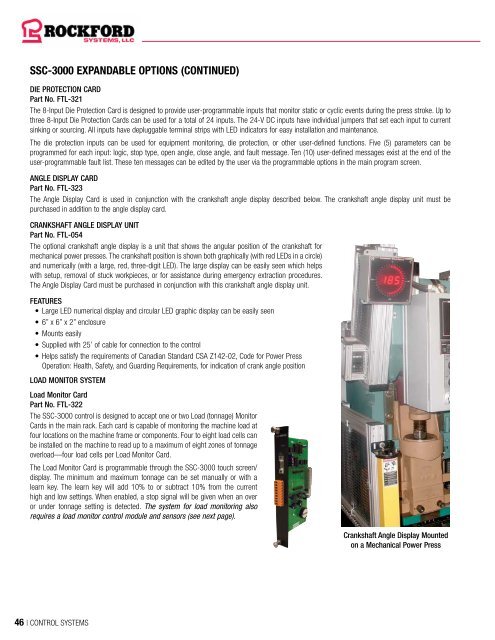

The optional crankshaft angle display is a unit that shows the angular position of the crankshaft <strong>for</strong><br />

mechanical power presses. The crankshaft position is shown both graphically (with red LEDs in a circle)<br />

and numerically (with a large, red, three-digit LED). The large display can be easily seen which helps<br />

with setup, removal of stuck workpieces, or <strong>for</strong> assistance during emergency extraction procedures.<br />

The Angle Display Card must be purchased in conjunction with this crankshaft angle display unit.<br />

FEATURES<br />

• Large LED numerical display and circular LED graphic display can be easily seen<br />

• 6” x 6” x 2” enclosure<br />

• Mounts easily<br />

• Supplied with 25’ of cable <strong>for</strong> connection to the control<br />

• Helps satisfy the requirements of Canadian Standard CSA Z142-02, Code <strong>for</strong> Power Press<br />

Operation: Health, Safety, and Guarding Requirements, <strong>for</strong> indication of crank angle position<br />

LOAD MONITOR SYSTEM<br />

Load Monitor Card<br />

Part No. FTL-322<br />

The SSC-3000 control is designed to accept one or two Load (tonnage) Monitor<br />

Cards in the main rack. Each card is capable of monitoring the machine load at<br />

four locations on the machine frame or components. Four to eight load cells can<br />

be installed on the machine to read up to a maximum of eight zones of tonnage<br />

overload—four load cells per Load Monitor Card.<br />

The Load Monitor Card is programmable through the SSC-3000 touch screen/<br />

display. The minimum and maximum tonnage can be set manually or with a<br />

learn key. The learn key will add 10% to or subtract 10% from the current<br />

high and low settings. When enabled, a stop signal will be given when an over<br />

or under tonnage setting is detected. The system <strong>for</strong> load monitoring also<br />

requires a load monitor control module and sensors (see next page).<br />

Crankshaft Angle Display Mounted<br />

on a Mechanical Power Press<br />

46 | CONTROL SYSTEMS