Wood brochure - South Africa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Klingspor solutions for the wood trade and furniture industry<br />

Stationary sanding<br />

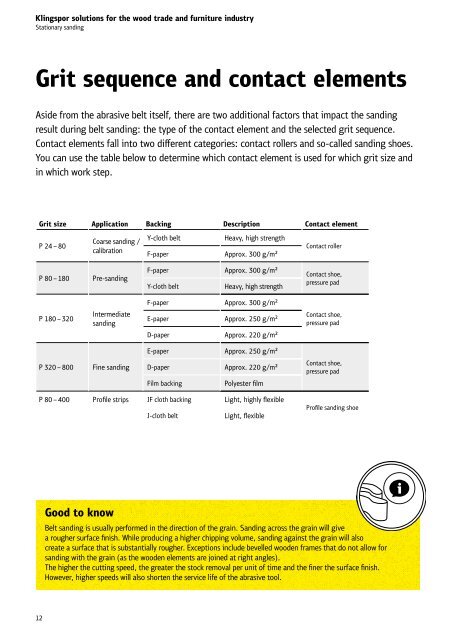

Grit sequence and contact elements<br />

Aside from the abrasive belt itself, there are two additional factors that impact the sanding<br />

result during belt sanding: the type of the contact element and the selected grit sequence.<br />

Contact elements fall into two different categories: contact rollers and so-called sanding shoes.<br />

You can use the table below to determine which contact element is used for which grit size and<br />

in which work step.<br />

Grit size Application Backing Description Contact element<br />

P 24 – 80<br />

Coarse sanding /<br />

calibration<br />

Y-cloth belt<br />

F-paper<br />

Heavy, high strength<br />

Approx. 300 g/m²<br />

Contact roller<br />

P 80 – 180<br />

Pre-sanding<br />

F-paper<br />

Y-cloth belt<br />

Approx. 300 g/m²<br />

Heavy, high strength<br />

Contact shoe,<br />

pressure pad<br />

P 180 – 320<br />

Intermediate<br />

sanding<br />

F-paper<br />

E-paper<br />

D-paper<br />

Approx. 300 g/m²<br />

Approx. 250 g/m²<br />

Approx. 220 g/m²<br />

Contact shoe,<br />

pressure pad<br />

E-paper<br />

Approx. 250 g/m²<br />

P 320 – 800<br />

Fine sanding<br />

D-paper<br />

Approx. 220 g/m²<br />

Contact shoe,<br />

pressure pad<br />

Film backing<br />

Polyester film<br />

P 80 – 400 Profile strips JF cloth backing Light, highly flexible<br />

J-cloth belt<br />

Light, flexible<br />

Profile sanding shoe<br />

Good to know<br />

Belt sanding is usually performed in the direction of the grain. Sanding across the grain will give<br />

a rougher surface finish. While producing a higher chipping volume, sanding against the grain will also<br />

create a surface that is substantially rougher. Exceptions include bevelled wooden frames that do not allow for<br />

sanding with the grain (as the wooden elements are joined at right angles).<br />

The higher the cutting speed, the greater the stock removal per unit of time and the finer the surface finish.<br />

However, higher speeds will also shorten the service life of the abrasive tool.<br />

12