Wood brochure - South Africa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Klingspor solutions for the wood trade and furniture industry<br />

Sanding with handheld machines<br />

Factors affecting the sanding with<br />

handheld machines<br />

Sander<br />

The quality / roughness of the surface is largely determined by the grit size used. The smaller the grit size,<br />

the finer the scratch pattern and vice versa: While increasing the stock removal rate and the penetration depth<br />

of the grit, a bigger grit size will generally also result in a rougher surface.<br />

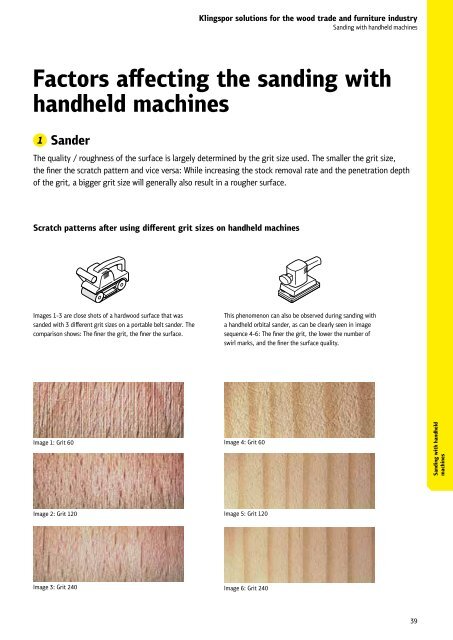

Scratch patterns after using different grit sizes on handheld machines<br />

Images 1-3 are close shots of a hardwood surface that was<br />

sanded with 3 different grit sizes on a portable belt sander. The<br />

comparison shows: The finer the grit, the finer the surface.<br />

This phenomenon can also be observed during sanding with<br />

a handheld orbital sander, as can be clearly seen in image<br />

sequence 4-6: The finer the grit, the lower the number of<br />

swirl marks, and the finer the surface quality.<br />

Image 1: Grit 60<br />

Image 4: Grit 60<br />

Sanding with handheld<br />

machines<br />

Image 2: Grit 120<br />

Image 5: Grit 120<br />

Image 3: Grit 240<br />

Image 6: Grit 240<br />

39