Wood brochure - South Africa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Klingspor solutions for the wood trade and furniture industry<br />

Sanding with handheld machines<br />

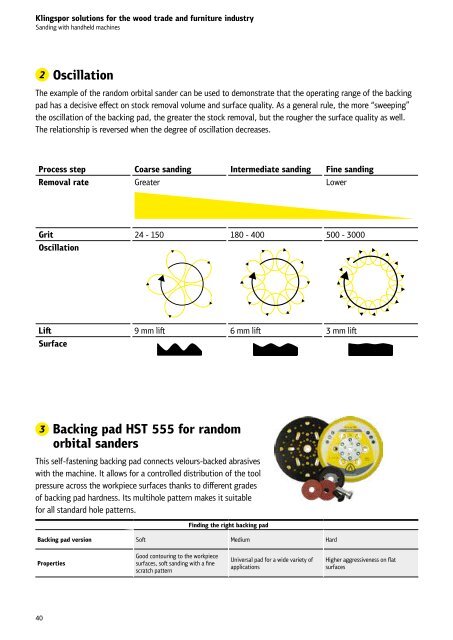

Oscillation<br />

The example of the random orbital sander can be used to demonstrate that the operating range of the backing<br />

pad has a decisive effect on stock removal volume and surface quality. As a general rule, the more “sweeping”<br />

the oscillation of the backing pad, the greater the stock removal, but the rougher the surface quality as well.<br />

The relationship is reversed when the degree of oscillation decreases.<br />

Process step Coarse sanding Intermediate sanding Fine sanding<br />

Removal rate Greater Lower<br />

Grit 24 - 150 180 - 400 500 - 3000<br />

Oscillation<br />

Lift 9 mm lift 6 mm lift 3 mm lift<br />

Surface<br />

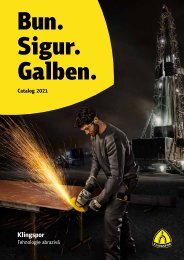

Backing pad HST 555 for random<br />

orbital sanders<br />

This self-fastening backing pad connects velours-backed abrasives<br />

with the machine. It allows for a controlled distribution of the tool<br />

pressure across the workpiece surfaces thanks to different grades<br />

of backing pad hardness. Its multihole pattern makes it suitable<br />

for all standard hole patterns.<br />

Finding the right backing pad<br />

Backing pad version Soft Medium Hard<br />

Properties<br />

Good contouring to the workpiece<br />

surfaces, soft sanding with a fine<br />

scratch pattern<br />

Universal pad for a wide variety of<br />

applications<br />

Higher aggressiveness on flat<br />

surfaces<br />

40